Method for preparing concrete micro-expansion agent from industrial solid waste steel slag

A technology of industrial solid waste and micro-expansion agent, applied in the field of building materials, can solve the problems of high grinding energy consumption, long storage time, poor grindability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

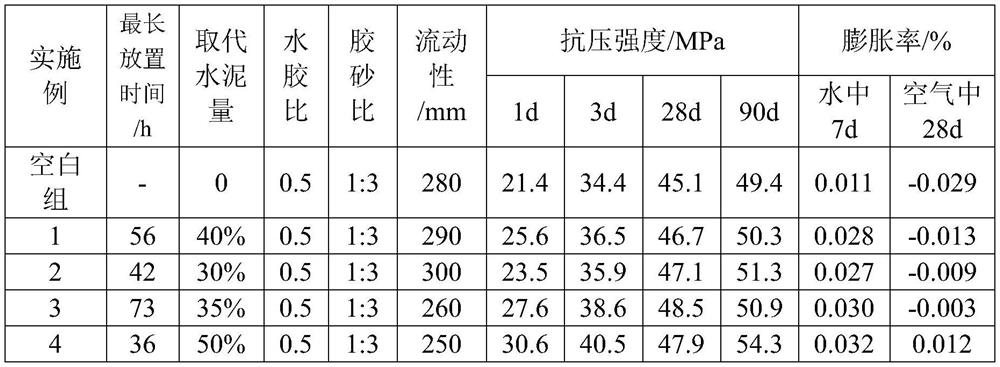

Embodiment 1

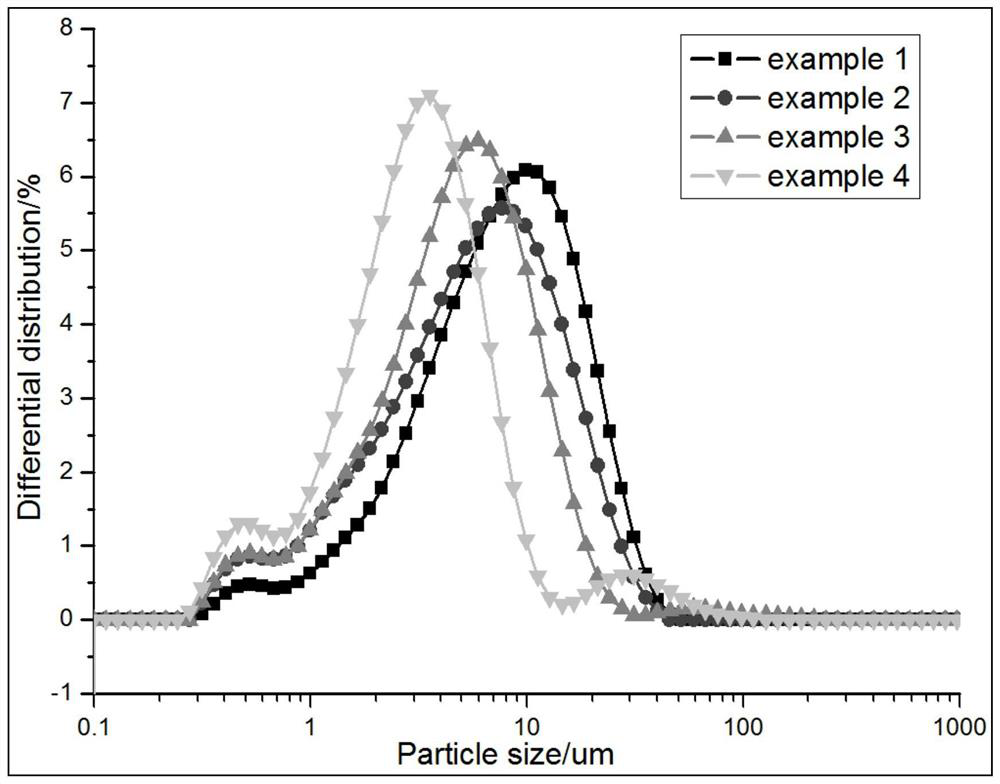

[0039] 1) After the industrial solid waste steel slag is crushed to a particle size of 10mm, then demagnetized and screened to remove the iron phase in the steel slag;

[0040] After demagnetization and screening, the content of elemental iron in steel slag is 0.5-2%;

[0041] 2) Take 100 parts of steel slag after step 1) demagnetization and screening, and put 80 parts of water in a wet drum type ball mill for ball milling to obtain fluid slurry; 1.5, the grinding ball is made of high manganese steel;

[0042] 3) Take the fluid slurry obtained in step 2) and place it in a vertical sand mill for wet grinding until the median particle size of the steel slag particles reaches 8 μm, the gradation interval of the grinding balls is 1.5-2.6 mm, and the ball-to-material ratio 1.5, the grinding ball is made of alumina;

[0043] 4) Add sodium methylene bis-naphthalene sulfonate and 0.4% sodium hexametaphosphate in an amount of 0.1% by mass fraction of steel slag to the steel slag part...

Embodiment 2

[0045] 1) After crushing the industrial solid waste steel slag to a particle size of 20 mm, then demagnetize and screen to remove the iron phase in the steel slag;

[0046] After demagnetization and screening, the content of elemental iron in steel slag is 0.5-2%;

[0047] 2) Take 100 parts of steel slag after demagnetization and screening in step 1), and put 100 parts of water in a wet roller ball mill to obtain a fluid slurry; 1.8, the material of the grinding ball is low alloy wear-resistant steel;

[0048] 3) Take the fluid slurry obtained in step 2) and place it in a vertical sand mill for wet grinding until the median particle size of the steel slag particles reaches 6 μm, the grading range of the grinding balls is 1.5-2.3 mm, and the ball-to-material ratio 1.8, the material of the grinding ball is zirconia;

[0049] 4) Add 0.3% polycarboxylate superplasticizer and 0.3% lignin sulfonate to the steel slag particles with a median particle size of 6 μm obtained in step 2)...

Embodiment 3

[0051] 1) After crushing industrial solid waste steel slag to a particle size of 25 mm, demagnetization and screening are performed to remove the iron phase in the steel slag;

[0052] After demagnetization and screening, the content of elemental iron in steel slag is 0.5-2%;

[0053] 2) Take 100 parts of steel slag after demagnetization and screening in step 1), and put 90 parts of water in a wet roller ball mill to obtain fluid slurry; 2.3, the material of the grinding ball is chromium molybdenum silicon manganese steel;

[0054] 3) Take the fluid slurry obtained in step 2) and place it in a vertical sand mill for wet grinding until the median particle size of the steel slag particles reaches 5 μm, the grading range of the grinding balls is 1.0-2.0 mm, and the ball-to-material ratio 2.2, the grinding ball is made of alloy steel;

[0055] 4) Add 0.2% polycarboxylate superplasticizer and 0.6% sucrose to the steel slag particles with a median particle size of 5 μm obtained in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com