TiB2 whisker high-temperature strengthening and toughening Ti (C, N)-based metal ceramic material preparation method

A ceramic material, strengthening and toughening technology, applied in the field of cermet tool materials and its preparation, can solve the problems of high-temperature strength and hardness of the tool, SiC whiskers and TiC whiskers are easy to oxidize at high temperatures, etc., to achieve high-temperature strength and Excellent toughness, industrial application, and good comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

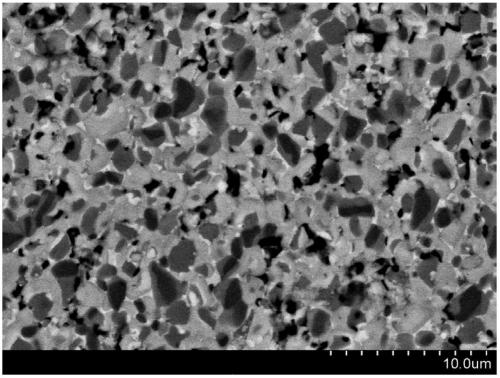

Image

Examples

Embodiment 1

[0031] Embodiment 1: a kind of TiB 2 A method for preparing a whisker high-temperature toughened Ti(C,N)-based cermet material, comprising the following steps:

[0032] Step 1: Carry out the proportioning of reaction raw materials; Take respectively Ti (C, N): 50g, TiB 2 Whisker: 25g, WC: 5g, Mo 2 C: 3g, TaC: 4g, NbC: 4g, Co: 4g, Ni: 5g.

[0033] Step 2: Add 15g of paraffin wax and 5g of sulfuric acid to the powder selected in step 1, then mix it evenly on the mixer, and granulate it with a granulator. The granulated powder is dried on the dryer to become the final powder. TiB above 2 Whiskers select high-strength TiB 2 Whiskers, the diameter of whiskers is between 300 and 1000nm, and the aspect ratio is between 1:10 and 1:30.

[0034] Step 3: Select a suitable resin abrasive according to the shape of the selected tool, then pour the material and vacuum seal it. Finally, it is put into hydraulic oil for cold isostatic pressing, and the forming pressure is 200MPa. The f...

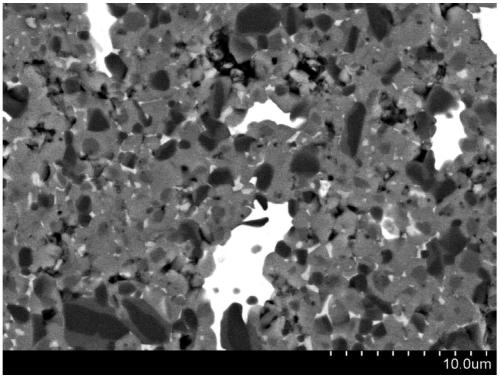

Embodiment 2

[0037] Embodiment 2: a kind of TiB 2 A method for preparing a whisker high-temperature toughened Ti(C,N)-based cermet material, comprising the following steps:

[0038] Step 1: Carry out the ratio of reaction raw materials; get Ti(C,N):60g, TiB respectively 2 Whisker: 20g, WC: 3g, Mo 2 C: 3g, TaC: 3g, NbC: 3g, Co: 4g, Ni: 4g.

[0039] Step 2: Add paraffin wax: 17g and sulfuric acid: 3g to the powder selected in step 1, then mix it evenly on the mixer, and granulate it with a granulator. The granulated powder is dried on the dryer to become the final powder. TiB above 2 Whiskers select high-strength TiB 2 Whiskers, the diameter of whiskers is between 300 and 1000nm, and the aspect ratio is between 1:10 and 1:30.

[0040] Step 3: Select a suitable resin abrasive according to the shape of the selected tool, then pour the material and vacuum seal it. Finally, it is put into hydraulic oil for cold isostatic pressing, and the forming pressure is 250MPa. The formed green body...

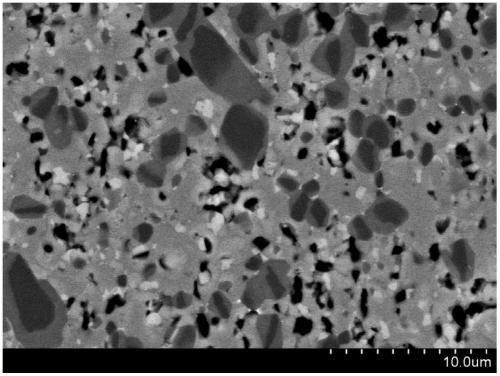

Embodiment 3

[0043] Embodiment 3: a kind of TiB 2 A method for preparing a whisker high-temperature toughened Ti(C,N)-based cermet material, comprising the following steps:

[0044] Step 1: Carry out the proportioning of reaction raw materials; Get respectively Ti (C, N): 55g, TiB 2 Whisker: 15g, WC: 5g, Mo 2 C: 5g, TaC: 5g, NbC: 5g, Co: 5g, Ni: 5g.

[0045] Step 2: Add paraffin wax: 10g, sulfuric acid: 10g to the powder selected in step 1, and then mix it evenly on the mixer, and then granulate it with a granulator. The granulated powder is dried on the dryer to become the final powder. TiB above 2 Whiskers select high-strength TiB 2 Whiskers, the diameter of whiskers is between 300 and 1000nm, and the aspect ratio is between 1:10 and 1:30.

[0046] Step 3: Select a suitable resin abrasive according to the shape of the selected tool, then pour the material and vacuum seal it. Finally, it is put into hydraulic oil for cold isostatic pressing, and the forming pressure is 150MPa. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

| High temperature hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com