Method and system for preparing ultrathin metal lithium films through magnetron sputtering

An ultra-thin metal, magnetron sputtering technology, applied in sputtering coating, metal material coating process, ion implantation coating and other directions, can solve the problem of unfavorable current uniform distribution, small specific surface area of metal lithium negative electrode, and uneven surface and other problems, to achieve the effect of improving volume energy density and safety, uniform surface current density distribution, and uniform and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

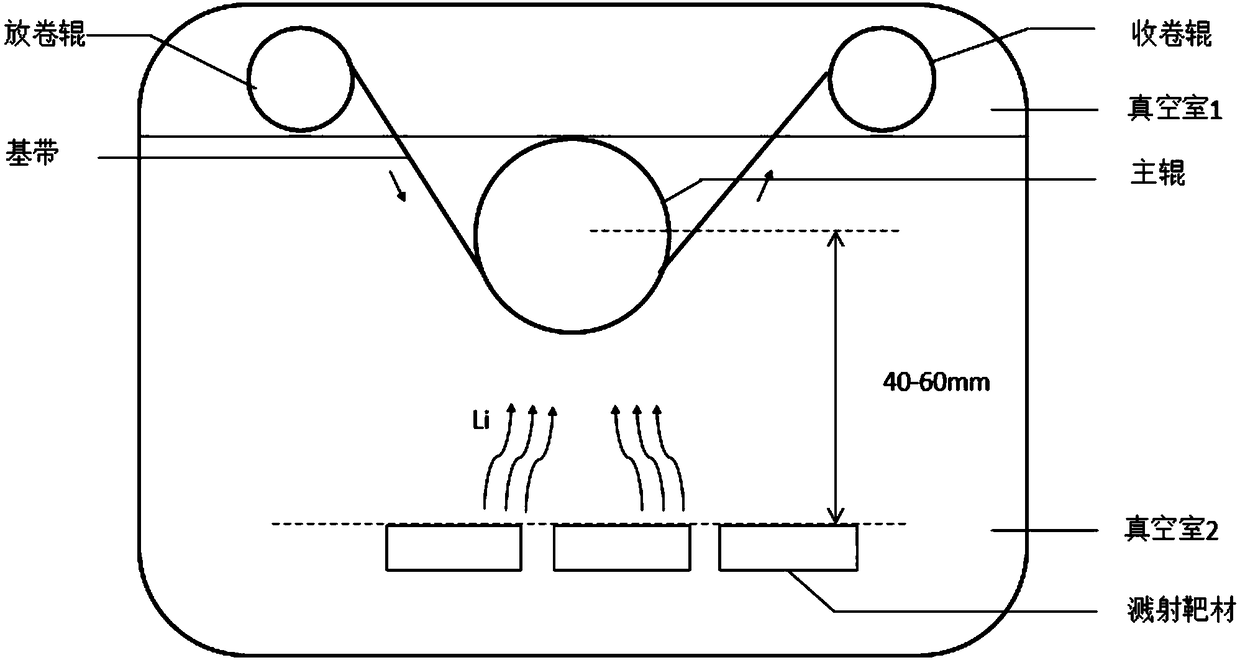

Embodiment 1

[0062] The flexible substrate to be sputtered used in this embodiment is a metal copper foil with a thickness of 20 μm. Prepare battery-grade lithium metal into the required target shape and put it in the sputtering studio. The vacuum degree of vacuum chamber 2 reaches 1×10 -4 After Pa, the DC magnetron sputtering system was turned on, the power was 50W, and the current was 3A. Unwind roll at 1m min -1 The copper foil is sent out at a constant speed. During the sputtering process, the working pressure of the vacuum chamber 2 is 1Pa, and the pressure of the winding chamber (vacuum chamber 1) is 6×10 -1 Pa. Argon flow is 10cm 3 s -1 , The target base distance (the distance from the target to the center of the main roller) is 60mm, the substrate temperature is 60℃, and the deposition time is 1min. After testing, the thickness of the metal lithium film after sputtering is 10 μm ± 1 μm.

Embodiment 2

[0064] The flexible substrate to be sputtered used in this embodiment is a high temperature resistant polyester film (PET film) with a thickness of 30 μm. Prepare battery-grade lithium metal into the required target shape and put it in the sputtering studio. The vacuum degree of vacuum chamber 2 reaches 1×10 -3 After Pa, turn on the DC magnetron sputtering system with a power of 30W and a current of 1A. Unwind roller at 0.4m min -1 The PET film is sent out at a constant speed. The working pressure of vacuum chamber 2 during sputtering is 5×10 -1 Pa, the pressure of the winding chamber (vacuum chamber 1) is 2×10 -1 Pa. Argon flow is 40cm 3 s -1 , The target base distance (the distance from the target to the center of the main roller) is 40mm, the substrate temperature is 80°C, and the deposition time is 10min. After testing, the thickness of the metal lithium film after sputtering is 20μm±1μm.

Embodiment 3

[0066] The flexible substrate to be sputtered used in this embodiment is a metal copper foil with a thickness of 6 μm. The surface treatment of 6μm copper foil by radio frequency plasma is carried out in advance, and the treatment time is 2min. Prepare battery-grade lithium metal into the required target shape and put it in the sputtering studio. The vacuum degree of vacuum chamber 2 reaches 8×10 -4 After Pa, the DC magnetron sputtering system was turned on, the power was 35W, and the current was 2A. Unwind roller at 0.8m min -1 The copper foil is sent out at a constant speed. The working pressure of vacuum chamber 2 during sputtering is 6×10 -1 Pa, the pressure of the winding chamber (vacuum chamber 1) is 5×10 -1 Pa. Argon flow rate is 15cm 3 s -1 , The target base distance (the distance from the target to the center of the main roller) is 50mm, the substrate temperature is 70℃, and the deposition time is 5min. After testing, the thickness of the metallic lithium film after...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com