Biodegradable material for preservation box, preservation box and preparation method of preservation box

A degradable material and biodegradation technology, applied in the field of biodegradable polymer materials, can solve the problems of product toughness, reduced physical and mechanical properties of plasticity, poor toughness, poor physical and mechanical properties of plasticity, and poor compatibility between polylactic acid and starch. Achieve the effect of improving plasticity and degradability, improving plasticity and toughening effect, excellent mechanical properties and processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

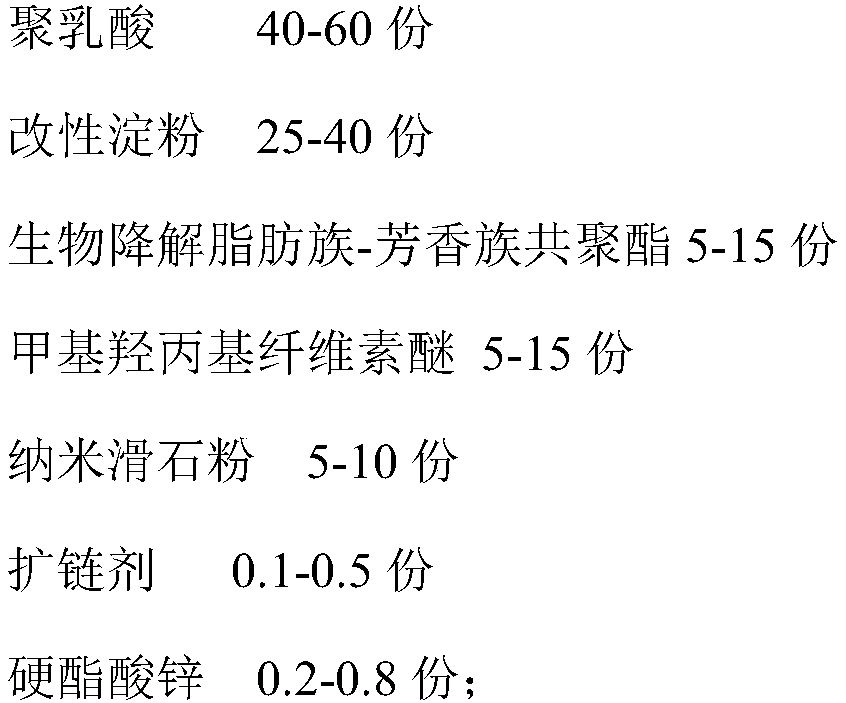

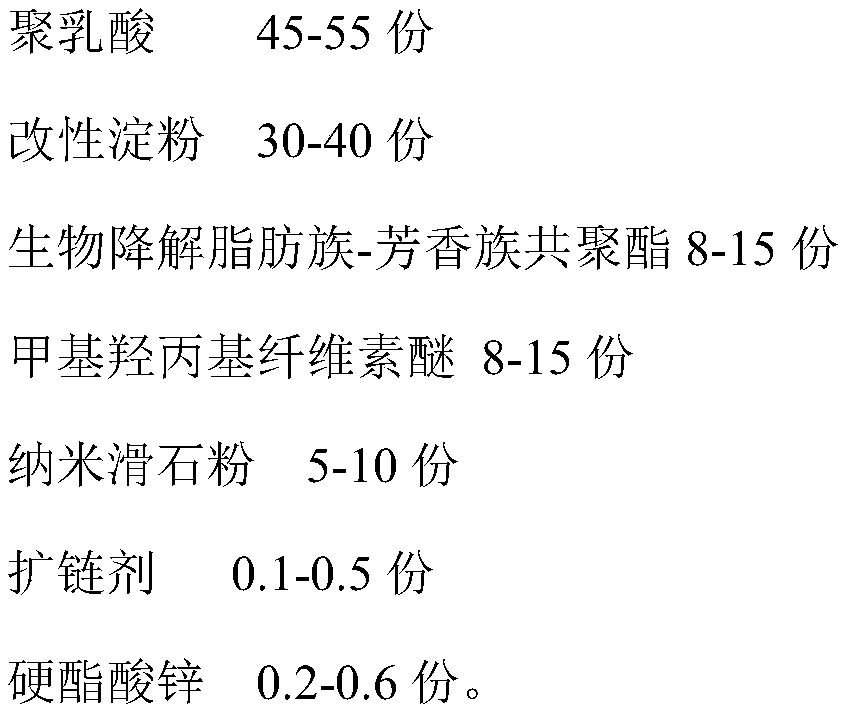

Method used

Image

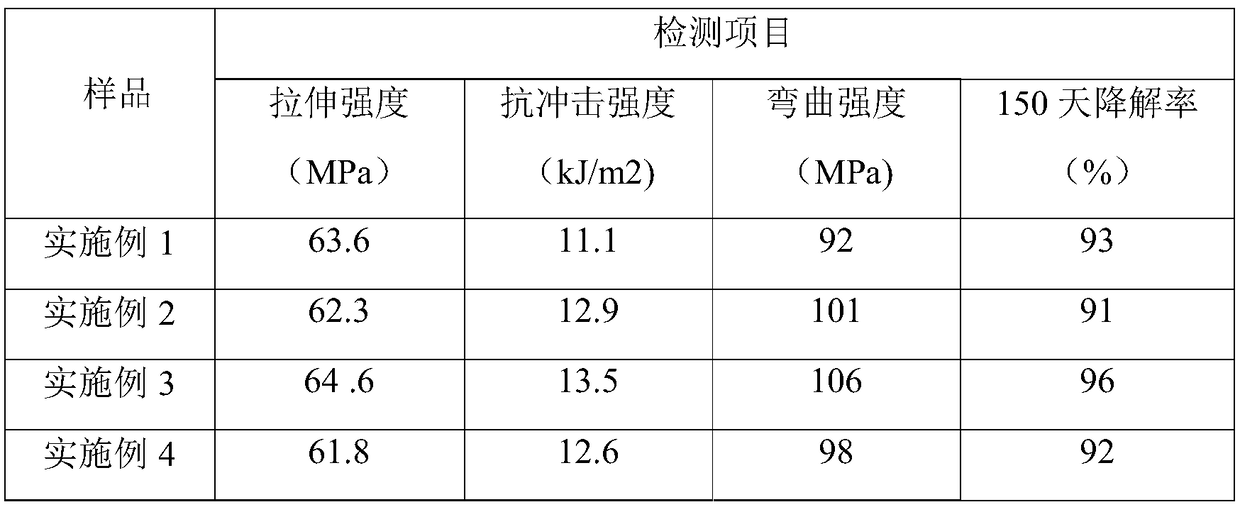

Examples

Embodiment 1

[0035] A fresh-keeping box of the present embodiment includes a box body and a box cover, and the box body and the box cover are prepared by the following steps (the following components are all calculated in parts by weight):

[0036] Step a. At 20°C, mix 50 parts of starch with 50 parts of distilled water and stir evenly, then add 4 parts of glycerin and 0.6 parts of maleic anhydride, and keep stirring to form a colloidal mixture; then place in a water bath or oil Heating gelatinization in a bath pot, the heating temperature is 95°C, the time is 25min, and viscous colloid is obtained; the viscous colloid is placed in an oven, the drying temperature is 100°C, and after baking for 15min, the dried The solid is crushed to 200 mesh to obtain modified starch;

[0037] Step b, weigh 30 parts of modified starch, 40 parts of polylactic acid, 8 parts of biodegradable aliphatic-aromatic copolyesters, 10 parts of methyl hydroxypropyl cellulose ether, 5 parts of nano talcum powder (aver...

Embodiment 2

[0042] A fresh-keeping box of the present embodiment includes a box body and a box cover, and the box body and the box cover are prepared by the following steps (the following components are all calculated in parts by weight):

[0043] Step a. At 22°C, mix 45 parts of starch and 55 parts of distilled water and stir evenly, then add 2 parts of glycerin and 0.4 parts of maleic anhydride, and keep stirring to form a colloidal mixture; then place in a water bath or oil Heat gelatinization in a bath pot, the heating temperature is 85 ° C, and the time is 30 minutes to obtain a viscous colloid; the viscous colloid is placed in an oven at a drying temperature of 110 ° C for 20 minutes, and the dried The solid is crushed to 100 mesh to obtain modified starch;

[0044] Step b, weigh 40 parts of modified starch, 45 parts of polylactic acid, 5 parts of polyethylene terephthalate-co-adipate, 8 parts of methyl hydroxypropyl cellulose ether, 6 parts of nano talc powder (average particle si...

Embodiment 3

[0049] A fresh-keeping box of the present embodiment includes a box body and a box cover, and the box body and the box cover are prepared by the following steps (the following components are all calculated in parts by weight):

[0050] Step a. At 25°C, mix 60 parts of starch with 45 parts of distilled water and stir evenly, then add 8 parts of glycerin and 1 part of maleic anhydride, and keep stirring to form a colloidal mixture; then place in a water bath or oil Heating and gelatinization in a bathing pot, the heating temperature is 100°C, and the time is 10 minutes to obtain a viscous colloid; the viscous colloid is placed in an oven at a drying temperature of 120°C, and after baking for 10 minutes, the dried The solid was crushed to 230 mesh to obtain modified starch;

[0051] Step b, weigh 35 parts of modified starch, 55 parts of polylactic acid, 12 parts of biodegradable aliphatic-aromatic copolyester, 15 parts of methyl hydroxypropyl cellulose ether, 8 parts of nanometer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com