Thermosetting resin composition, prepreg produced by using thermosetting resin composition, and metal foil clad laminate

A technology of resin composition and prepreg, which is applied in the direction of metal layered products, synthetic resin layered products, applications, etc., can solve the problems of inability to meet the needs of high-frequency signal transmission, deterioration of dielectric properties, and large polarity, and achieve improvement Drillability, excellent dielectric properties, and the effect of improving brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0098]0.481 moles (68.4 mL) of vinylbenzene, 0.0362 moles (5.16 mL) of ethyl vinylbenzene, and 63 mL of dichloroethane solution (concentration: 0.634 mmol / mL) of 1-chlorovinylbenzene (40 mmol), brominated Put 11 mL of tetra-n-butylammonium (1.5 mmol) in dichloroethane (concentration: 0.135 mmol / mL) and 500 mL of dichloroethane into a 1000 mL flask, and add 1.5 mmol of SnCl at 70°C 4 Dichloroethane solution (concentration: 0.068mmol / mL) 1.5mL, reaction time 1 hour. After the polymerization reaction is terminated by a small amount of methanol that has been foamed with nitrogen, the reaction mixture is dropped into a large amount of methanol at room temperature to precipitate the polymer, and the obtained polymer is washed with methanol, filtered, dried, and weighed to obtain a copolymer The product VOD-A was 54.6g in total (yield 49.8wt%).

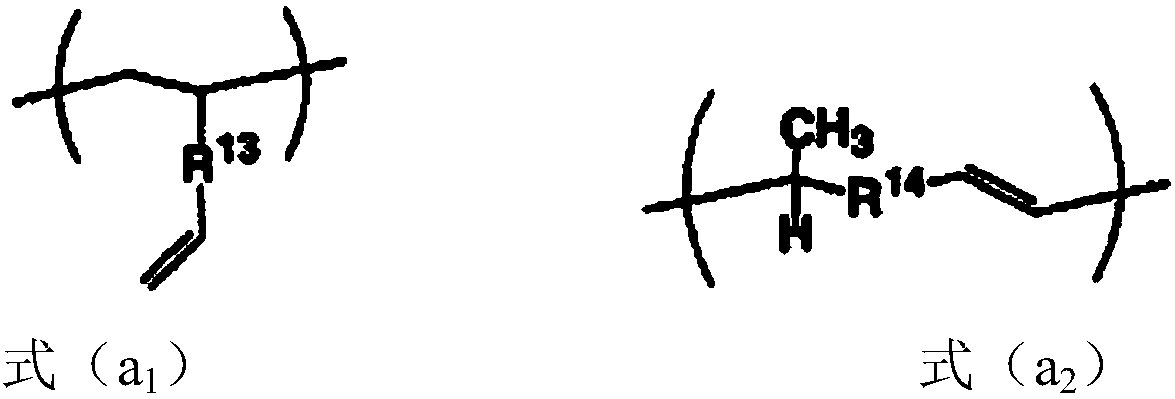

[0099] The obtained polymer VOD-A had Mw of 4180, Mn of 2560, and Mw / Mn of 1.6. The polymer VOD-A contains 52 mol% of structural units de...

preparation example 2

[0102] 0.481 moles (68 mL) of vinylbenzene, 0.362 moles (52 mL) of ethyl vinylbenzene, 47 mL of dichloroethane solution (concentration: 0.634 mmol / mL) of 1-chlorovinylbenzene (30 mmol), tetra-n-chloride Put 65 mL of butylammonium (2.25 mmol) in dichloroethane (concentration: 0.035 mmol / mL) and 500 mL of dichloroethane into a 1000 mL flask, and add 1.5 mmol of SnCl at 70°C 4 Dichloroethane solution (concentration: 0.068mmol / mL) 22mL, reaction time 1 hour. After the polymerization reaction is terminated by a small amount of methanol that has been foamed with nitrogen, the reaction mixture is dropped into a large amount of methanol at room temperature to precipitate the polymer, and the obtained polymer is washed with methanol, filtered, dried, and weighed to obtain a copolymer The product VOD-B was 67.4g in total (yield 61.4wt%).

[0103] The obtained polymer VOD-B had Mw of 7670, Mn of 3680, and Mw / Mn of 2.1. The polymer VOD-B contains 51 mol% of structural units derived from...

preparation example 3

[0106] Vinylbenzene 0.0481 moles (6.84mL), ethyl vinylbenzene 0.0362 moles (5.16mL), the following general formula (a 5 )

[0107]

[0108] (where, R 30 is isopropyl, Py is pyridyl)

[0109] Put 12.0mg of the cobalt-based chain transfer agent and 150ml of tetrahydrofuran into a 300ml flask, and then add 2,2'-azobis(2,4-dimethylvaleronitrile) at 50°C for 72 hours. Drop the reaction mixture into a large amount of methanol at room temperature to precipitate the polymer, wash the obtained polymer with methanol, filter, dry, and weigh to obtain a total of 3.15 g of copolymer VOD-C (yield 28.7 wt%).

[0110] The obtained polymer VOD-C contains gel, so it is only soluble in THF solvent, its Mw is 94600, Mn is 12800, and Mw / Mn is 7.4. The polymer VOD-C contains 58 mol% of structural units derived from divinylbenzene and 42 mol% of structural units derived from ethylvinylbenzene as measured by a JNM-LA600 nuclear magnetic resonance spectrometer manufactured by JEOL Ltd. It was a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com