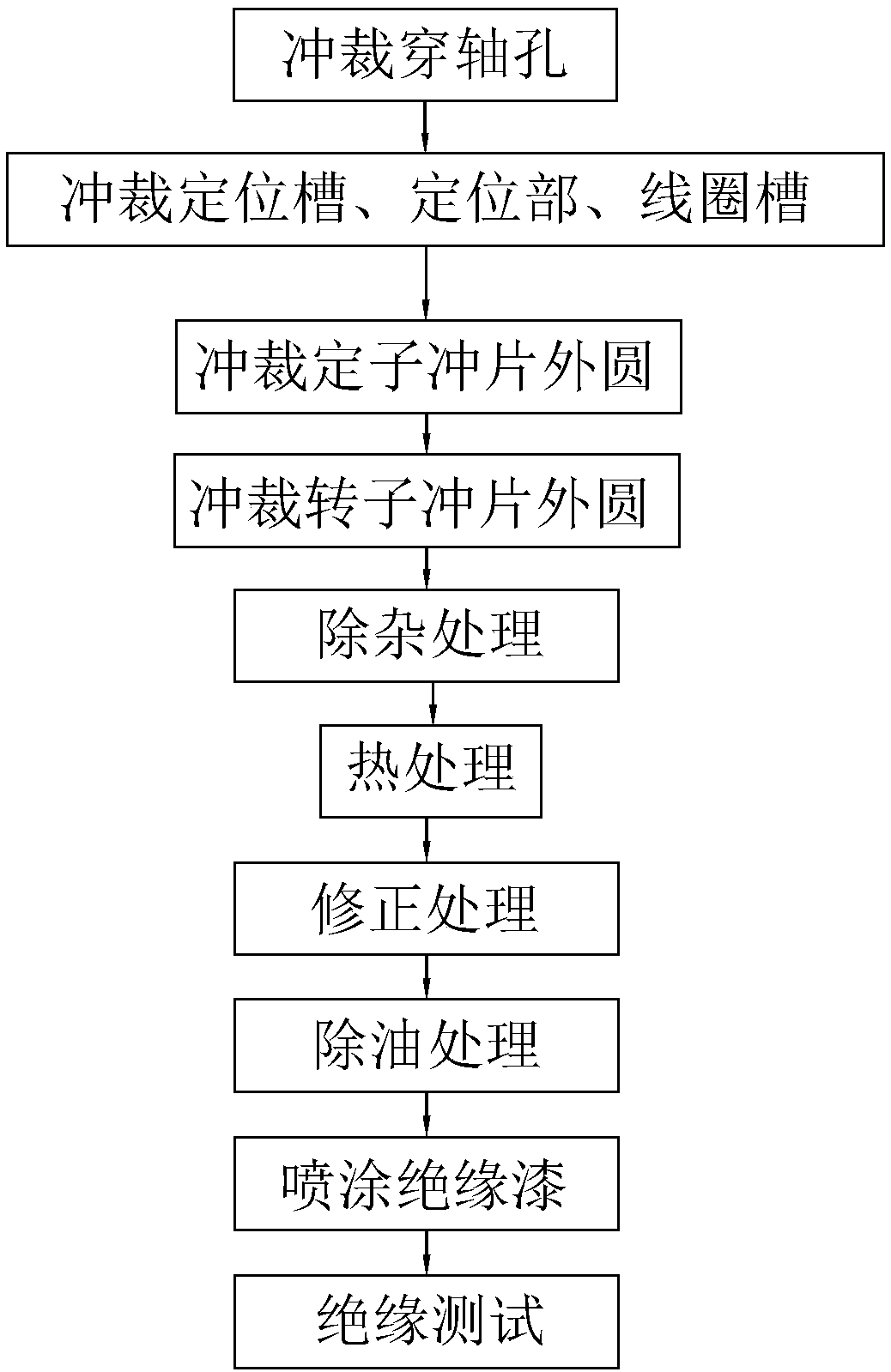

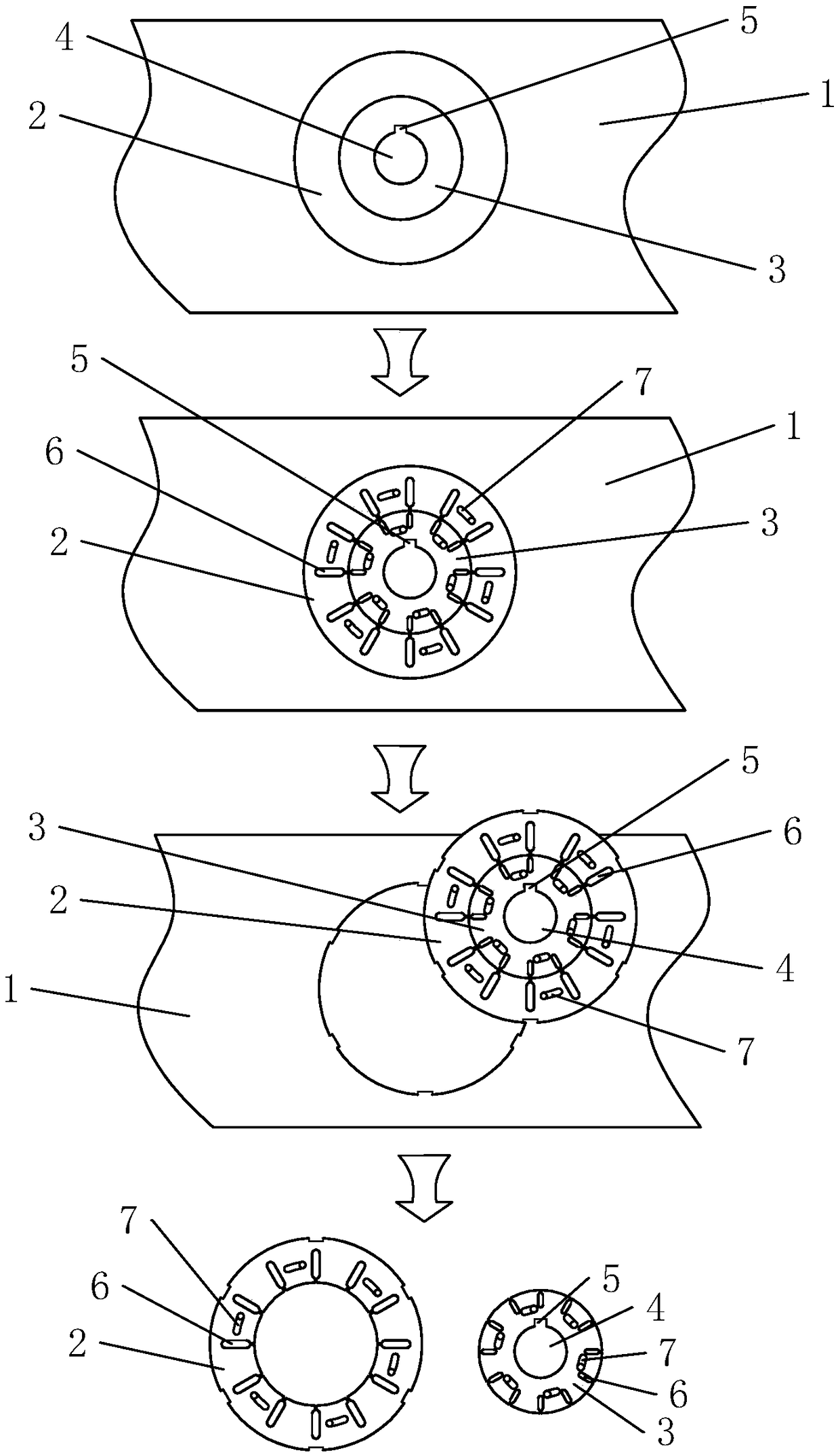

Rotor punching piece manufacturing process

A technology of rotor punching and manufacturing process, which is applied in the field of rotor punching manufacturing technology, can solve problems such as high vibration intensity, distance deviation, and poor processing accuracy, and achieve the effects of increasing magnetic permeability, reducing vibration intensity, and improving processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

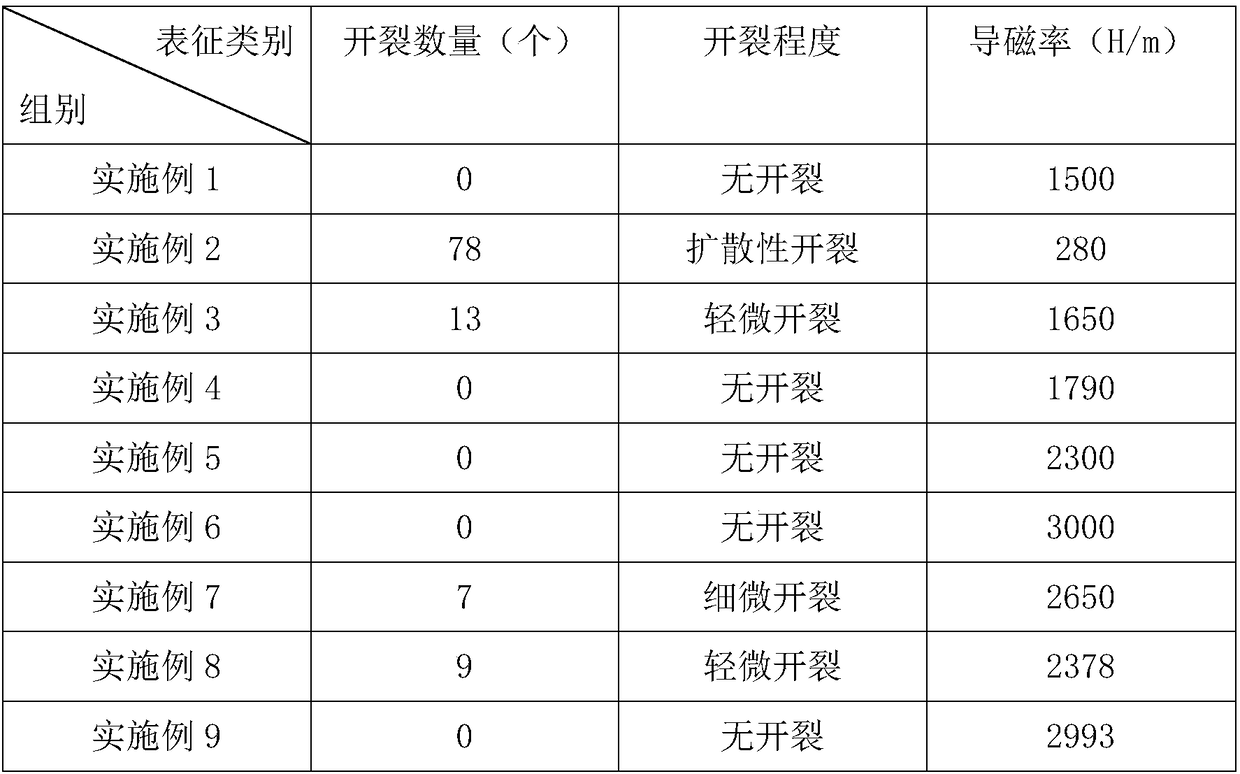

Embodiment 1

[0052] Example 1: The stamped sheet is not subjected to any heat treatment.

Embodiment 2

[0053] Embodiment 2: The punched piece is directly immersed in tap water for one-time cooling and quenching.

Embodiment 3

[0054] Embodiment 3: Punching is divided into two stages of initial cooling and final cooling for cooling and quenching, and the initial cooling stage is 5L / min·m 2 The spraying speed is sprayed on the punching sheet, and after the punching sheet is cooled to 600-700 degrees Celsius, switch to 8L / min·m 2 Spray the punched sheet at the final cooling spray speed until the punched sheet cools to room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com