A kind of room temperature high ductility magnesium alloy and preparation method thereof

A magnesium alloy, high plasticity technology, applied in the field of magnesium alloys, metal materials and metal material processing, can solve the problems of low room temperature plasticity of magnesium alloys, and achieve the effects of inhibiting grain growth, texture optimization, and inhibiting excessive growth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

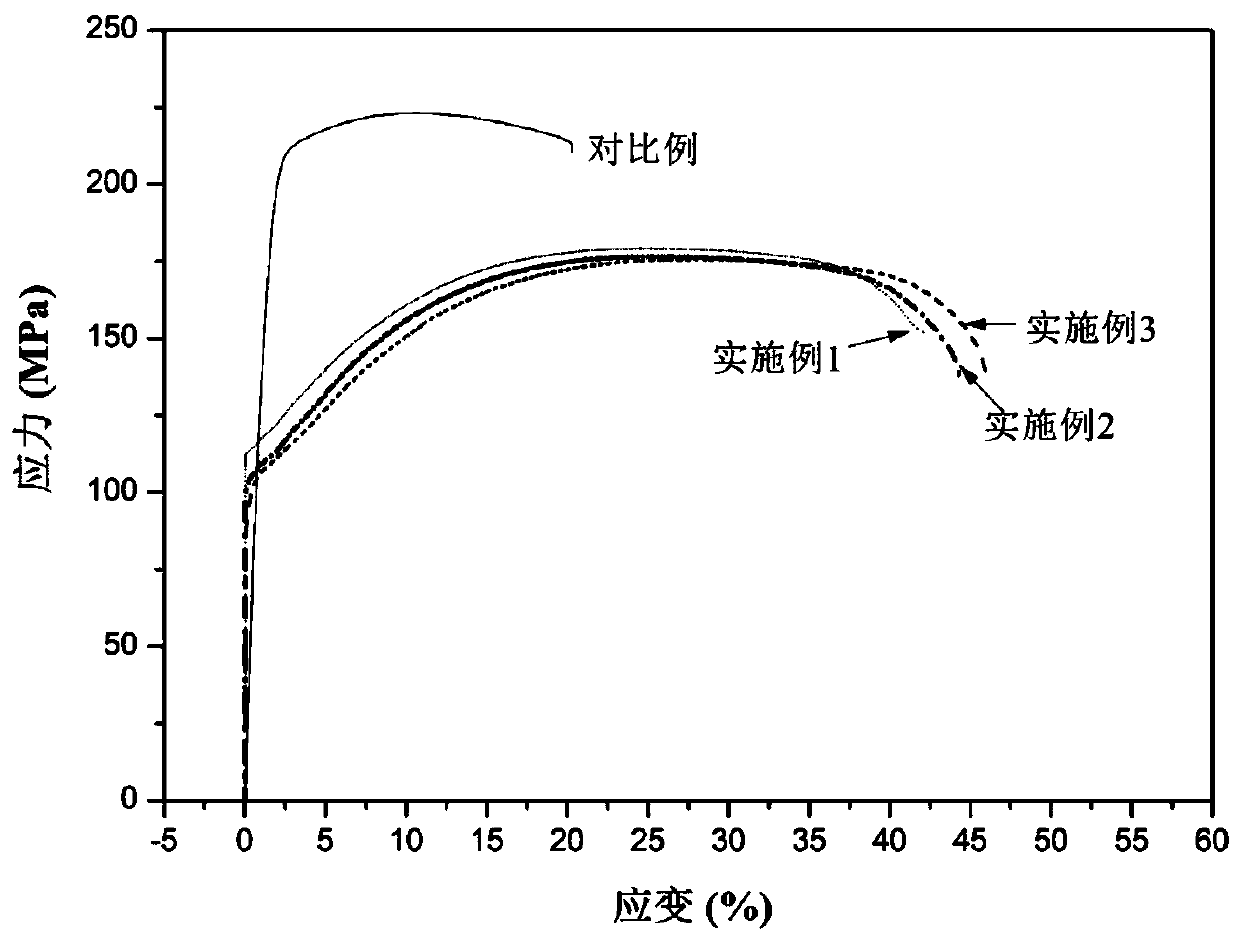

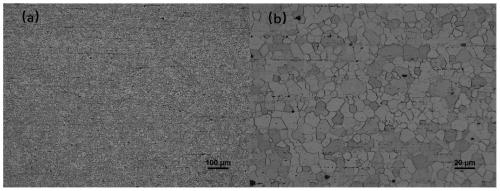

Embodiment 1

[0044] (1) Design and select Mg-5Bi-2.8Y-0.06Mn (wt%) alloy composition ratio to form a magnesium alloy, and the preparation method includes the following steps:

[0045] 1) Ingredients: Use pure Mg ingot, pure Bi block, Mg-30Y master alloy and Mg-10Mn master alloy as raw materials, after surface pretreatment (such as removal of dirt, scale, etc., the same as the following examples), according to the above objectives ingredients for batching;

[0046] 2) Melting: Set the furnace temperature to 700-730°C. When the furnace temperature rises to the predetermined temperature, put the pure Mg ingot preheated to 200°C into the crucible of the melting furnace. Add the pure Bi block at 50°C and the Mg-Y master alloy preheated to 200°C into the molten magnesium; then increase the melting temperature to 750-760°C and keep it warm for 10 minutes, then stir for 5 minutes and let stand for 5 minutes , add Mg-10Mn master alloy, keep it warm for 10 minutes, then stir for 5 minutes, lower th...

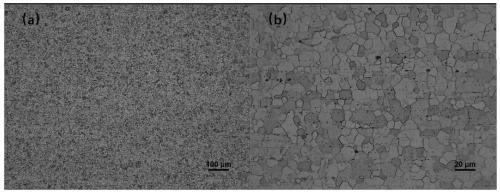

Embodiment 2

[0054] (1) design and select Mg-6.0Bi-3Y-0.08Mn (wt%) alloy composition ratio to form a magnesium alloy, and the preparation method includes the following steps:

[0055] 1) Ingredients: Use pure Mg ingot, pure Bi block, Mg-30Y master alloy and Mg-10Mn master alloy as raw materials, after surface pretreatment (such as removal of dirt, scale, etc., the same as the following examples), according to the above objectives ingredients for batching;

[0056] 2) Melting: Set the furnace temperature to 700-730°C. When the furnace temperature rises to the predetermined temperature, put the pure Mg ingot preheated to 200°C into the crucible of the melting furnace. Add the pure Bi block at 50°C and the Mg-Y master alloy preheated to 200°C into the molten magnesium; then increase the melting temperature to 750-760°C and keep it warm for 10 minutes, then stir for 5 minutes and let stand for 5 minutes , add Mg-10Mn master alloy, keep it warm for 10 minutes, then stir for 5 minutes, lower th...

Embodiment 3

[0064] (1) The design selects the Mg-4.5Bi-2.3Y-0.05Mn (wt%) alloy composition ratio to form a magnesium alloy, and the preparation method comprises the following steps:

[0065] 1) Ingredients: Use pure Mg ingot, pure Bi block, Mg-30Y master alloy and Mg-10Mn master alloy as raw materials, after surface pretreatment (such as removal of dirt, scale, etc., the same as the following examples), according to the above objectives ingredients for batching;

[0066] 2) Melting: Set the furnace temperature to 700-730°C. When the furnace temperature rises to the predetermined temperature, put the pure Mg ingot preheated to 200°C into the crucible of the melting furnace. Add the pure Bi block at 50°C and the Mg-Y master alloy preheated to 200°C into the molten magnesium; then increase the melting temperature to 750-760°C, keep it warm for 10 minutes, and then stir for 5 minutes.

[0067] Stand still for 5 minutes, add Mg-10Mn master alloy, and keep warm for 10 minutes, then stir for 5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com