A melting sampling-X ray fluorescent spectrometry for determining primary and secondary components of ferromolybdenum alloy

A fluorescence spectrometry, molybdenum-iron alloy technology, applied in the field of fusion sample preparation-X-ray fluorescence spectrometry, to achieve the effects of easy to master, few operation steps, and short analysis period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

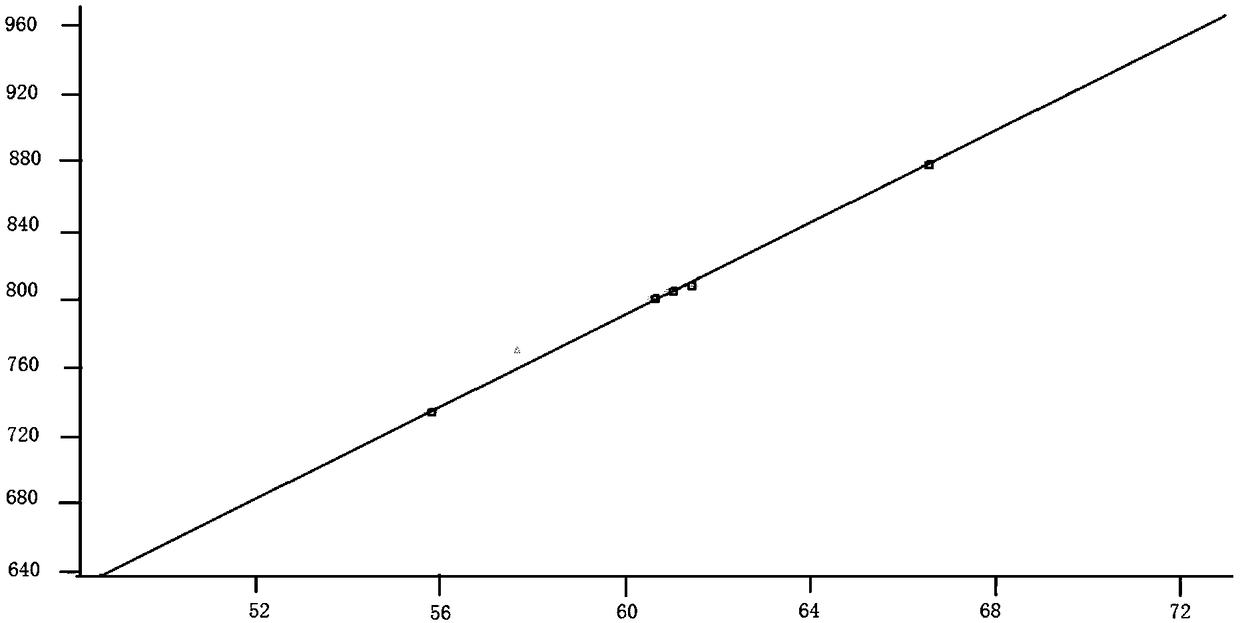

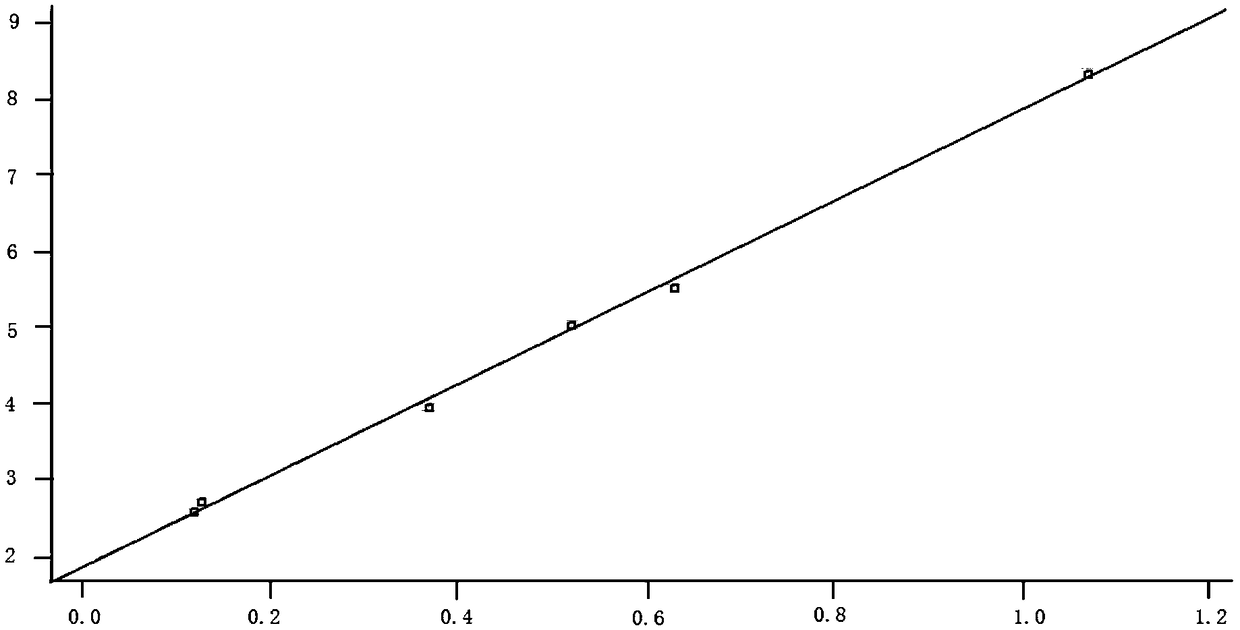

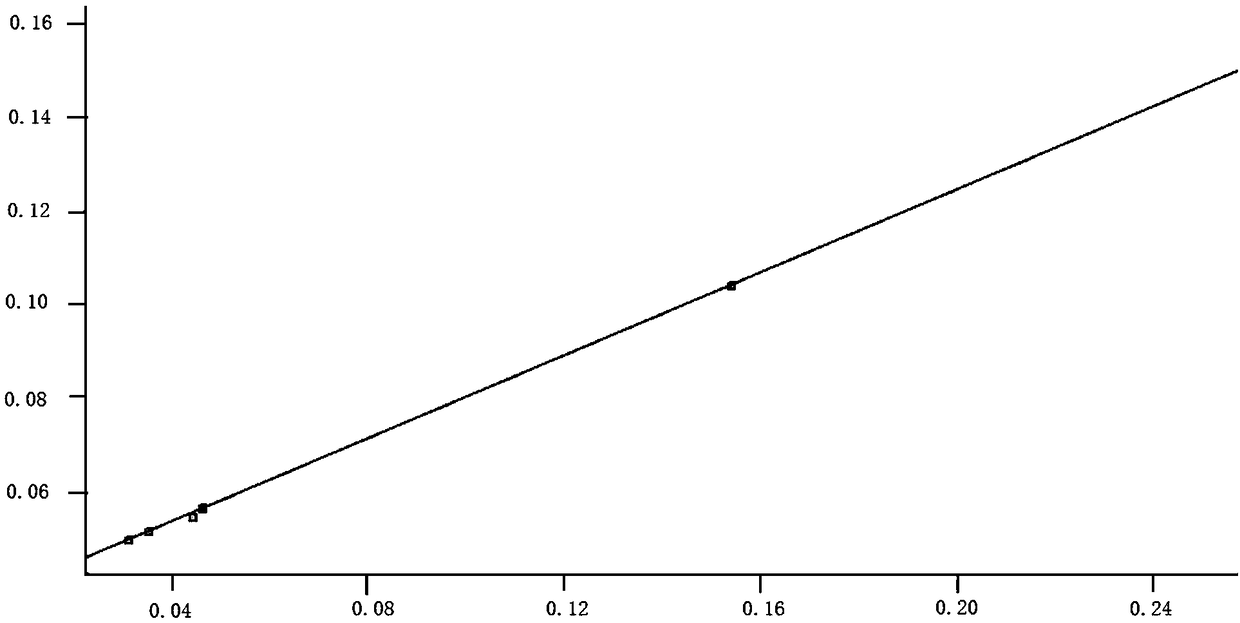

[0046] Establishment of working curve of X-ray fluorescence spectrometer

[0047] a: Select 6 standard samples of ferromolybdenum, and the content range should cover the content of the analysis sample. Weigh 25g of the standard sample and grind it with a vibrating mill for 30s, all of which can pass through a 180-mesh sieve. Accurately weigh 0.2500g of the ground standard sample into a porcelain crucible, add 2.2500g of mixed oxidant and 1.0000g of lithium tetraborate flux, and stir evenly. 8.0000g of lithium tetraborate flux and 0.250g of ammonium iodide mold release agent were weighed into a platinum crucible, stirred evenly with a glass rod, and the center was slightly concave. Slowly pour the mixed standard into the groove.

[0048] b: Put the above-mentioned crucible into the electric melting furnace with the programmed program, and about 25 minutes after the start button is clicked, a uniform and transparent glass sheet for analysis is prepared.

[0049] c: According ...

Embodiment 2

[0051] 1. Select 6 ferromolybdenum standard samples, the content range is shown in Table 1 below. Weigh 25g of the standard sample and grind it with a vibrating mill for 30s, all of which can pass through a 180-mesh sieve. Accurately weigh 0.2500g of the ground standard sample into a porcelain crucible, add 2.2500g of mixed oxidant and 1.0000g of lithium tetraborate flux, and stir evenly. 8.0000g of lithium tetraborate flux and 0.250g of ammonium iodide mold release agent were weighed into a platinum crucible, stirred evenly with a glass rod, and the center was slightly concave. Slowly pour the mixed standard into the groove.

[0052] Table 1 standard sample of molybdenum iron

[0053] serial number

name

Standard No.

Mo content / %

Cu content / %

P content / %

1

YSBC18605-08

55.78

0.63

0.154

2

YSBC37653-10

57.65

0.117

0.046

3

YSBC28631-2010

6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com