Method for preparing vanadium trioxide powder by using one-step hydrothermal method

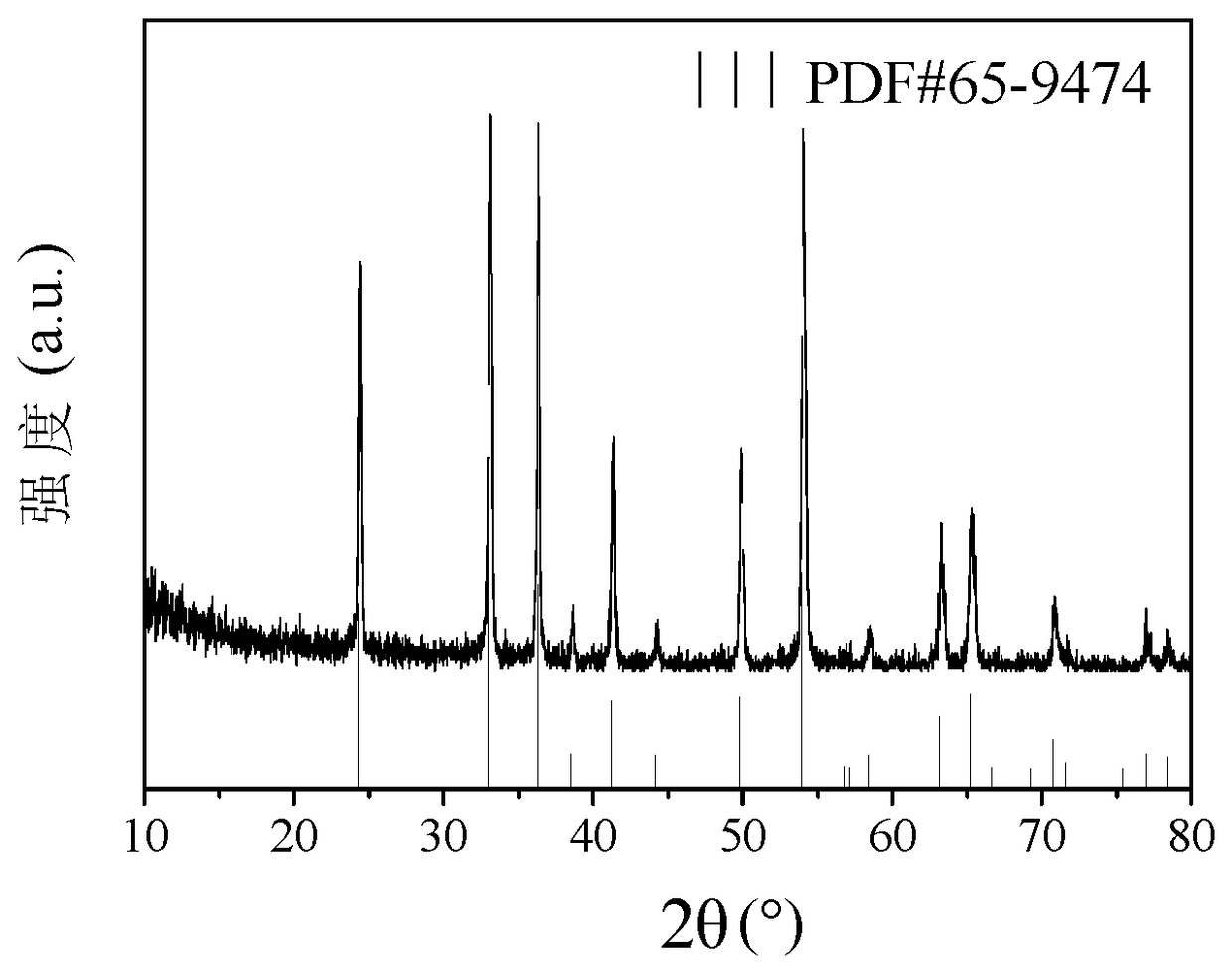

A vanadium trioxide and hydrothermal technology, applied in the direction of vanadium oxide, etc., can solve environmental pollution and other problems, and achieve the effects of easy control of reaction conditions, low reaction temperature and good crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

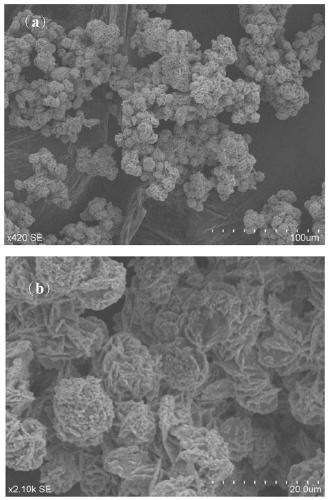

[0037] Weigh 1.218g Na 3 VO 4 Dissolved in 40mL of water under the action of magnetic stirring to obtain a clear and transparent solution, and then added 1.67g of C 2 h 2 o 4 2H 2 O, the color of the solution turned yellow. Transfer the reaction solution to a high-pressure reactor, heat it to 270°C, react for 48 hours, stop heating, and when the temperature of the reactor drops to room temperature, centrifuge to separate the solid powder and dry it to obtain vanadium trioxide micron powder. 10-20 μm.

Embodiment 2

[0039] Weigh 1.218g Na 3 VO 4 Dissolved in 40mL of water under the action of magnetic stirring to obtain a clear and transparent solution, and then added 1.67g of C 2 h 2 o 4 2H 2 O, the color of the solution turned yellow. Transfer the reaction solution to a high-pressure reactor, heat it to 300°C, react for 6 hours, stop heating, and when the temperature of the reactor drops to room temperature, centrifuge to separate the solid powder and dry it to obtain vanadium trioxide micron powder. 1 to 10 μm.

Embodiment 3

[0041] Weigh 1.218g Na 3 VO 4 Dissolved in 40mL of water under the action of magnetic stirring to obtain a clear and transparent solution, and then added 3.34g of C 2 h 2 o 4 2H 2 0, the solution color turns yellow, then adds 0.165g tungstic acid wherein. Transfer the reaction solution to a high-pressure reactor, heat it to 200°C, react for 48 hours, stop heating, and when the temperature of the reactor drops to room temperature, centrifuge to separate the solid powder and dry it to obtain micron powder of tungsten-doped vanadium trioxide , the particle size is 5-20 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com