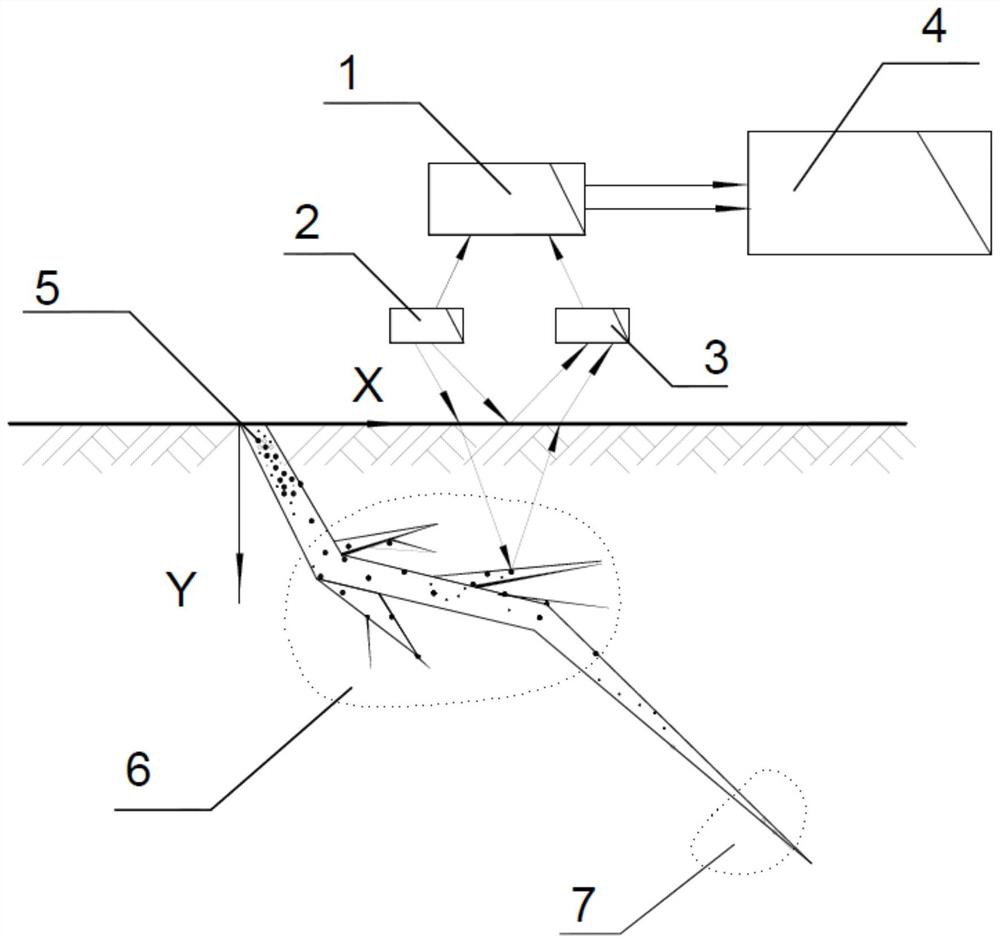

Preparation method of a fracture developer and its application method for rock mass fracture detection

A rock mass fissure and developer technology, which is applied to measuring devices, instruments, scientific instruments, etc., can solve the problems of weakening rock mass strength, a large number of drilling holes, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] A preparation method of a crack developer, which comprises the following steps:

[0048] S01: Prepare the crack developer masterbatch, pre-mix the nano-metal powder with 3 to 15 parts by weight and the microcrystalline graphite material with 1 to 5 parts by weight through a powder high-speed mixer to obtain The powder mixture is used as the crack developer masterbatch;

[0049] S02: Prepare crack developer fillers, add barium titanate to the polymer matrix, and perform 20 to 30 times of solid-phase shear milling to prepare high-dielectric polymers as crack developer fillers, wherein the cracks The volume fraction of the barium titanate in the developer filler is 0.3 to 0.5;

[0050] S03: Add 1 to 5 parts by weight of the cracked developer masterbatch and 0.2 to 0.5 parts by weight of the cracked developer filler into a high-speed stirring disperser, and stir for 5 to 15 minutes to obtain Fracture developer composites;

[0051] S04: adding distilled water to the composi...

Embodiment 1

[0065] Embodiment 1, a preparation method of a crack developer, which comprises the following steps:

[0066] S01: Prepare crack developer masterbatch, pre-mix 3 parts by weight of iron powder and 1 part by weight of chopped carbon fiber through a powder high-speed mixer to prepare a powder mixture as crack developer masterbatch grain;

[0067] S02: Prepare crack developer fillers, add barium titanate to polypropylene, and perform 20 times of solid phase shear milling to prepare high dielectric polymers as crack developer fillers, wherein the crack developer fillers The volume fraction of the barium titanate is 0.3, and the volume fraction of the polypropylene is 0.7;

[0068] S03: Add 1 part by weight of the cracked developer masterbatch and 0.2 parts by weight of the cracked developer filler into a high-speed stirring disperser, and stir for 5 minutes to obtain a cracked developer composite material;

[0069] S04: adding distilled water to the composite material of the cra...

Embodiment 2

[0071] Embodiment 2, a preparation method of a crack developer, which comprises the following steps:

[0072] S01: Prepare cracked developer masterbatch, pre-mix 3 parts by weight of copper powder and 1 part by weight of carbon fiber particles through a powder high-speed mixer, and prepare a powder mixture as cracked developer masterbatch ;

[0073] S02: Prepare crack developer fillers, add barium titanate to polypropylene, and perform 25 times of solid-phase shear milling to prepare high dielectric polymers as crack developer fillers, wherein the crack developer fillers The volume fraction of the barium titanate is 0.4, and the volume fraction of the polypropylene is 0.6;

[0074] S03: Add 3 parts by weight of the cracked developer masterbatch and 0.5 parts by weight of the cracked developer filler into a high-speed stirring disperser, and stir for 5 minutes to obtain a cracked developer composite material;

[0075] S04: adding distilled water to the composite material of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com