Wear-resistant repair coating and repair method for desulfurization slurry pump

A technology of desulfurization slurry and repair method, which is applied to coatings, devices for coating liquid on the surface, epoxy resin coatings, etc., can solve the problem that the wear resistance and bonding performance of coating repair materials cannot be combined at the same time. Achieve the effects of prolonging the continuous operation period, improving the bonding strength, and simplifying the repair process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

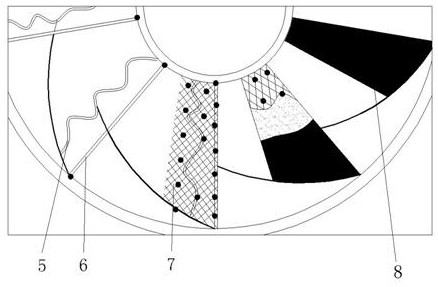

[0031] Impeller Repair of Desulfurization Slurry Pump

[0032] Pre-treatment of the impeller: For the area where the damaged blade 5 has a defect width greater than 20mm, the welded steel rod 6 is used as a boundary support column, and the welding method is spot welding. The welding points are at the contact points between the two ends of the steel rod 6 and the blade, and the diameter of the steel rod 6 is 3mm.

[0033]The welded rhombic expanded metal 7 fills the defect area of the blade, and the welding method is spot welding, and the welding spots are on the same plane as the contact point between the periphery of the expanded metal 7 and the damaged blade 5 and the steel rod 6 . The diagonal distance of the diamond-shaped holes of the expanded metal mesh 7 is 40mm, and the thickness is 2mm.

[0034] The steel rods 6 and the rhombic expanded metal 7 are used to build a skeleton for repair coating materials to adhere to in the blade defect area.

[0035] Repair of the i...

Embodiment 2

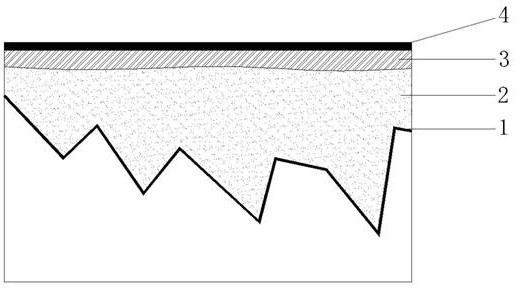

[0044] Repair of Pump Shell of Desulfurization Slurry Pump

[0045] Step 1. Sandblasting the surface to be repaired. After sandblasting, the roughness of the surface to be repaired is 60-100 μm. The sandblasting material used is white corundum sand with a mesh number of 8 mesh. The compressed air used for sandblasting is degreasing and drying. After clean air, the pressure of compressed air is 7Bar.

[0046] Step 2. Clean the surface to be repaired with xylene. After cleaning, wipe it with a white cloth. Repeated cleaning until there is no visible stain on the white cloth. After cleaning, blow the surface to be repaired with dry air until the xylene is completely volatilized.

[0047] Step 3, take by weighing 1000g bisphenol A type epoxy resin, 200g aluminum oxide powder (average particle diameter is 5 μm), 50g silane coupling agent, obtain primer main agent after mixing; Take by weighing 50g polyamine (diethylene triamine), 80g curing accelerator (2-ethyl-4-methylimidazole),...

Embodiment 3

[0053] Repair of the front and rear guards of the desulfurization slurry pump

[0054] Step 1. Sandblasting the surface to be repaired. After sandblasting, the roughness of the surface to be repaired is 60-80 μm. The sandblasting material used is white corundum sand with a mesh number of 8 mesh. The compressed air used for sandblasting is degreasing and drying. After clean air, the pressure of compressed air is 7Bar.

[0055] Step 2. Clean the surface to be repaired with xylene. After cleaning, wipe it with a white cloth. Repeated cleaning until there is no visible stain on the white cloth. After cleaning, blow the surface to be repaired with dry air until the xylene is completely volatilized.

[0056] Step 3, take by weighing 500g bisphenol A type epoxy resin, 400g aluminum oxide powder (average particle diameter is 5 μm), after mixing uniformly, obtain base coat main agent; Take by weighing 150g polyamine (m-xylylenediamine), 20g Curing accelerator (2-ethyl-4-methylimidazol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com