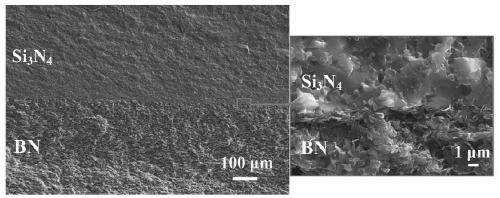

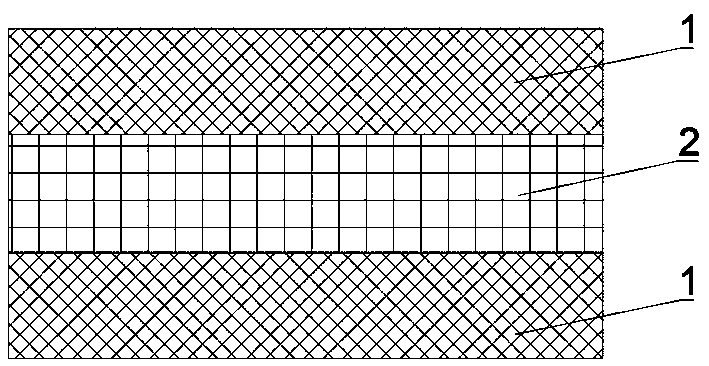

Boron nitride-silicon nitride sandwich wide-frequency wave-transmitting material and preparation method thereof

A wave-transmitting material, boron nitride technology, applied in ceramic products, other household utensils, applications, etc., can solve the problems of low atomic diffusion coefficient, excessive grain growth, and difficult sintering, etc., to achieve adjustable material microstructure, The heating rate is fast and the effect of grain growth can be controlled

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] A method for preparing a boron nitride-silicon nitride interlayer broadband wave-transmitting material of the present invention comprises the following steps:

[0043] S1. Mix the polymer monomer, crosslinking agent, dispersant, pore forming agent and deionized water to obtain a mixed solution; use silicon nitride ceramic powder and sintering aid I as the mixed solid phase, and add it to the mixed solution Perform ball milling pretreatment to obtain premixed slurry;

[0044] S2. Add a pH regulator to the premixed slurry obtained in step S1 until the pH value is 8.5 to 11.5, and ball mill to obtain a mixed slurry. The mixed slurry is vacuum degassed under stirring conditions, and an initiator is added for mixing. Obtain injection molding slurry;

[0045] S3. Perform injection molding on the injection molding slurry obtained in step S2, and perform demoulding, drying, and debinding treatment after the slurry is completely solidified to obtain a porous silicon nitride gre...

Embodiment 1

[0050] A method for preparing a boron nitride-silicon nitride interlayer broadband wave-transmitting material in this embodiment includes the following steps:

[0051] S1. Add 7g of acrylamide, 0.3g of N'N-methylenebisacrylamide, 400μL of dispersant JA-281 (density 1.06g / mL) and 10g of pore-forming agent n-hexane into 60mL of deionized water to form a mixed solution , then 100g silicon nitride ceramic powder, 3g sintering aid (Al 2 o 3 with SiO 2 Mass ratio 1:1) mixed with the prepared mixed solution, and ball milled for 60 minutes to obtain pre-mixed slurry;

[0052] S2. Add tetramethylammonium hydroxide to the premixed slurry obtained in step S1 until the pH of the premixed slurry is 9.8, and continue ball milling for 4 hours to obtain a mixed slurry; then stir and pump at a speed of 800r / min Remove the gas in the mixed slurry by vacuum, then add 2.44mL initiator (the aqueous solution of 2,2'-azo(2-methylpropyl ether) dihydrochloride with a mass fraction of 15% is used in...

Embodiment 2

[0065] The preparation method of the present embodiment is roughly the same as that of Example 1, except that:

[0066] In step S4, the sintering temperature is 1850° C., and the sintering pressure is 20 MPa.

[0067] Finally, a non-stripping boron nitride-silicon nitride interlayer broadband wave-transmitting material can be obtained.

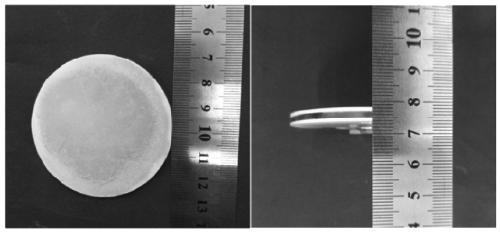

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com