Tungsten alloy coating preparation equipment and method

An alloy coating, tungsten alloy technology, applied in metal material coating process, coating, gaseous chemical plating and other directions, to achieve good high temperature resistance, improve the ability to resist high temperature gas oxidation erosion, reduce equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

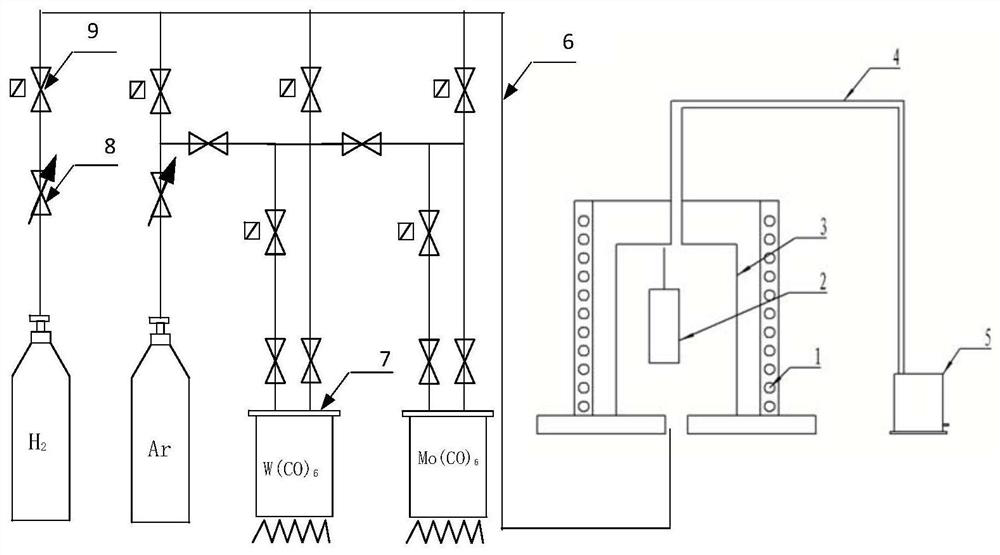

[0066] This embodiment provides a kind of preparation method of tungsten alloy coating:

[0067] Firstly, the sample 2 (sample 2 is a cuboid 30CrMnSi structure, length 100mm×width 60mm×height 5mm) after pretreatment such as sanding and drying is suspended in the reactor 3 . First pass pure argon and pure hydrogen to discharge the air in the reactor 3, adjust the temperature of the heating furnace 1 to 500°C, and then set W(CO) respectively 6 Evaporator, Mo(CO) 6 The heating temperature of the evaporator and the counter is 80°C and 90°C, and the gas flow rate is Q H2 =800ml / min, W(CO) 6 Argon carrying flow Q 载Ar1 =200ml / min, Mo(CO) 6 Carrier gas flow Q 载Ar2 =50ml / min, the deposition time is 2h, after the deposition is completed, continue to flow argon to cool to room temperature. The thickness of the coating is 50 microns, the content of tungsten in the coating is 93.8%, and the content of molybdenum is 6.2%. The neutral salt spray test is carried out on sample 2, and the...

Embodiment 2

[0069] This embodiment provides a kind of preparation method of tungsten alloy coating:

[0070] First, the sample 2 (sample 2 is a TC4 titanium alloy pipe fitting with an inner diameter of 25 mm, an outer diameter of 30 mm, and a length of 100 mm) that has been pretreated by sanding and drying is placed in the reactor 3 . First feed pure argon and pure hydrogen to discharge the air in the reactor 3, adjust the temperature of the heating furnace 1 to 700°C, and then set W(CO) respectively 6 Evaporator, Mo(CO) 6 The heating temperature of the evaporator and the counter is 80°C and 90°C, and the gas flow rate is Q H2 =600ml / min, W(CO)6 Argon carrying flow Q 载Ar1 =200ml / min, Mo(CO) 6 The carrier gas flow rate is Q 载Ar2 =100ml / min, the deposition time is 3h, after the deposition is completed, continue to flow argon gas to cool to room temperature. The thickness of the coating is 430 microns, the content of tungsten in the coating is 83.6%, and the content of molybdenum is 16....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com