A method for filling activated carbon in carbon fiber prefabricated body and its application

A carbon fiber preform and activated carbon technology, which is applied in the field of high-reactivity C/C preform preparation, can solve the problems of low cracking yield of precursors, inconvenient enlargement of high-pressure vessels, increased processes, etc., to meet the requirements of low cost, short cycle, The effect of solving equipment amplification bottlenecks and solving security problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Pretreatment of Aminophenolic Resin

[0039] 1) Pre-evaporation of phenolic resin

[0040] First, take 100ml of phenol-formaldehyde resin, put it in a flask, and evaporate it with a rotary evaporator at 60° C. and 1000 Pa for 40 minutes to remove 50-70 wt % of the solvent in the liquid phenol-formaldehyde resin.

[0041] 2) Preparation and drying of phenolic resin solution

[0042] Add 40ml of acetone to the pre-evaporated phenolic resin, stir evenly, and dry it with a spray dryer. The temperature of the hot argon gas is 80°C, and the feeding speed is 5ml / min. The dried phenolic resin becomes powder.

Embodiment 2

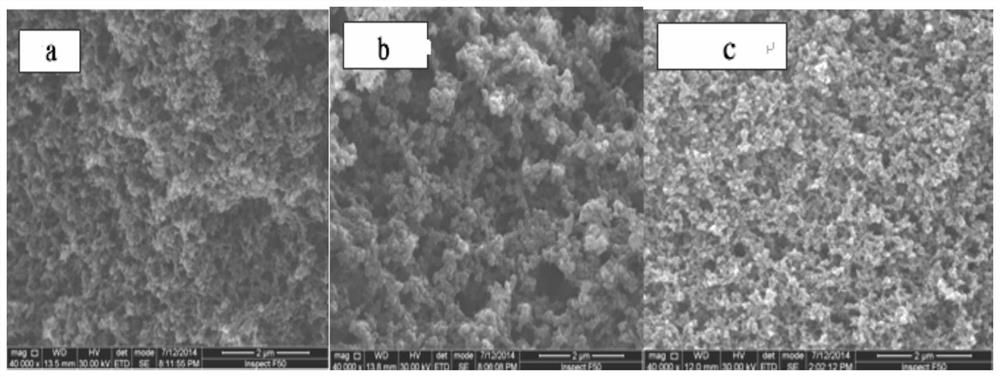

[0044] Atmospheric pressure crosslinking and curing of phenolic resin in different solvent systems to prepare activated carbon

[0045] 1) Prepare phenolic resin solution

[0046] First prepare the phenolic resin organic solution, get 40g of the phenolic resin powder prepared in Example 1 and dissolve them in 100ml glycerol (chemically pure), 90ml glycerin+10ml dimethyl sulfoxide mixed solution or 85ml glycerin+10ml dimethyl sulfoxide+ 5g polyether mixed solution, a transparent liquid was obtained after thorough stirring.

[0047] 2) Preparation of polymer by in situ polymerization

[0048] Pour the above solution into a 150ml glass bottle, put it into an electric heating constant temperature drying box to heat, the reaction temperature is 160°C, the holding time is 12 hours, and cool to room temperature.

[0049] 3) Washing, drying and grinding

[0050] The reaction product obtained in step 2) is soaked in ethanol or deionized water for 1-2 hours, filtered, dried in a cons...

Embodiment 3

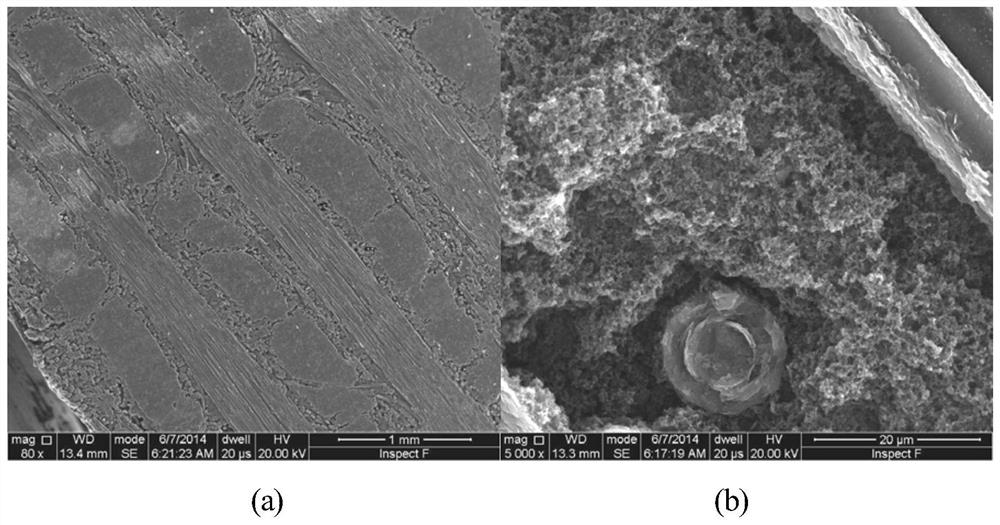

[0054] Atmospheric pressure assembly of activated carbon in carbon fiber prefabricated body

[0055] 1) Prepare phenolic resin solution

[0056] First prepare the phenolic resin organic solution, take 40g of the phenolic resin powder prepared in Example 1 and dissolve in 85ml of glycerin+10ml of dimethyl sulfoxide+5g of polyether mixed solution, after fully stirring, a transparent liquid is obtained.

[0057] 2) Atmospheric pressure filled activated carbon

[0058] The needle-punched carbon fiber preform was immersed in the phenolic resin solution prepared in step 1) by vacuum impregnation, and then placed in a polytetrafluoroethylene beaker, kept at 160°C for 12 hours, and then cooled to room temperature; the carbon fiber preform was taken out in the Perform pyrolysis at 900°C for 2 hours to obtain an activated carbon matrix; repeat the above vacuum impregnation-solvothermal polymerization-pyrolysis process 6 times to obtain a carbon fiber preform filled with an activated ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com