A kind of lead-free relaxation antiferroelectric ceramic energy storage material and preparation method thereof

An energy storage material and antiferroelectric technology, applied in the field of energy storage ceramic materials, can solve the problems of immature mass production technology, limited use range, small dielectric constant, etc., to improve energy storage density and energy storage efficiency , Improve energy storage efficiency and energy storage density, the effect of high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

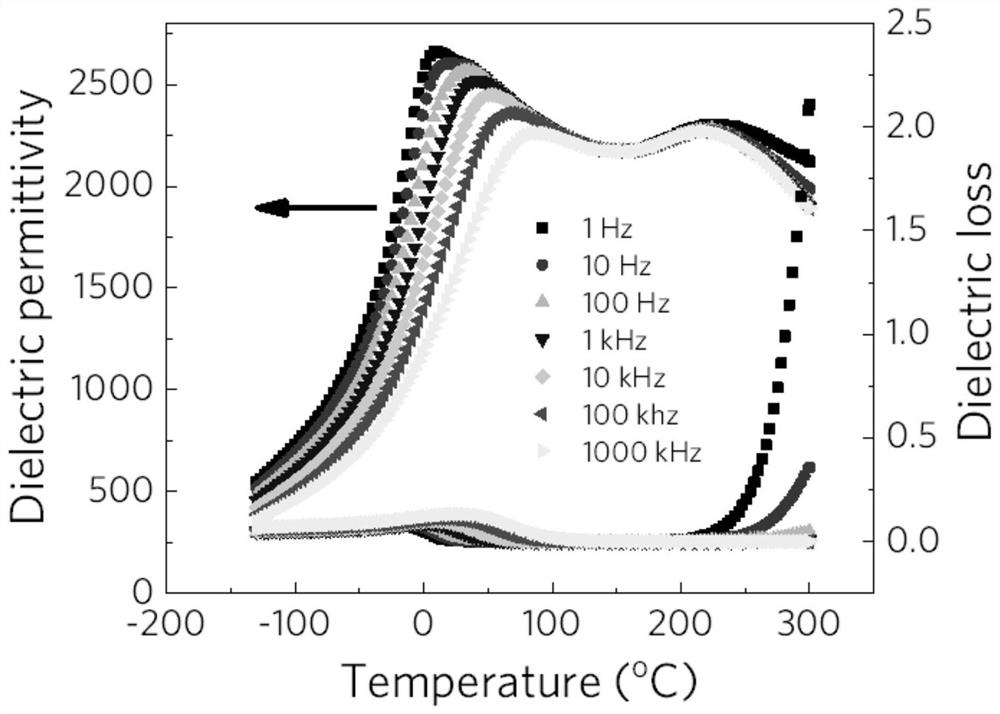

Image

Examples

Embodiment 1

[0027] The preparation method of the lead-free relaxor antiferroelectric ceramic energy storage material according to the present invention comprises the following steps:

[0028] 1) Based on La with a purity of 99.99% 2 O 3 Carry out batching, and then use anhydrous ethanol as a medium for ball milling for 12 hours to reduce the particle size of rare earth elements, and then dry at 200 ° C to obtain La 2 O 3 powder;

[0029] 2) Bi with a purity of 99.99% 2 O 3 , 99.99% Na 2 CO 3 and 99.99% TiO 2 As raw materials, weigh 116.52 grams, 26.63 grams and 80.06 grams respectively, and then put them into a ball-milling jar for ball-milling and mixing. During the ball-milling process, the volume of the raw material: the volume of the agate ball: the volume of the ball-milled meson anhydrous ethanol is equal to 1:2:4, The ball milling time was 12h, and then the ball-milled raw materials were put into an oven and dried at 80°C for 10h. After drying, the raw material was pressed...

Embodiment 2

[0035] The preparation method of the lead-free relaxor antiferroelectric ceramic energy storage material according to the present invention comprises the following steps:

[0036] 1) Based on Sm with a purity of 99.99% 2 O 3 Carry out batching, and then use anhydrous ethanol as a medium for ball milling for 12 hours to reduce the particle size of rare earth elements, and then dry at 200 ° C to obtain Sm 2 O 3 powder;

[0037] 2) Bi with a purity of 99.99% 2 O 3 , 99.99% Na 2 CO 3 and 99.99% TiO 2 As raw materials, weigh 116.52 grams, 26.63 grams and 80.06 grams respectively, and then put them into a ball-milling jar for ball-milling and mixing. During the ball-milling process, the volume of the raw material: the volume of the agate ball: the volume of the ball-milled meson anhydrous ethanol is equal to 1:2:4, The ball milling time was 12h, and then the ball-milled raw materials were put into an oven and dried at 80°C for 10h. After drying, the raw material was pressed...

Embodiment 3

[0042] The preparation method of the lead-free relaxor antiferroelectric ceramic energy storage material according to the present invention comprises the following steps:

[0043] 1) Based on Dy with a purity of 99.99% 2 O 3 Carry out batching, and then use anhydrous ethanol as a medium for ball milling for 12 hours to reduce the particle size of rare earth elements, and then dry at 200 ° C to obtain Dy 2 O 3 powder;

[0044] 2) Bi with a purity of 99.99% 2 O 3 , 99.99% Na 2 CO 3 and 99.99% TiO 2 As raw materials, weigh 116.52 grams, 26.63 grams and 80.06 grams respectively, and then put them into a ball-milling jar for ball-milling and mixing. During the ball-milling process, the volume of the raw material: the volume of the agate ball: the volume of the ball-milled meson anhydrous ethanol is equal to 1:2:4, The ball milling time was 12h, and then the ball-milled raw materials were put into an oven and dried at 80°C for 10h. After drying, the raw material was pressed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com