Rapid starting method of biological electrochemistry technology for removing oxygen from oil field wastewater

A technology of bioelectrochemistry and oilfield wastewater, which is applied in chemical instruments and methods, electrochemical and biological combined treatment, mining wastewater treatment, etc., can solve the problems of low power generation capacity of MFC operation, reduce oxygen corrosion, improve water quality, The effect of enhancing biodiversity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

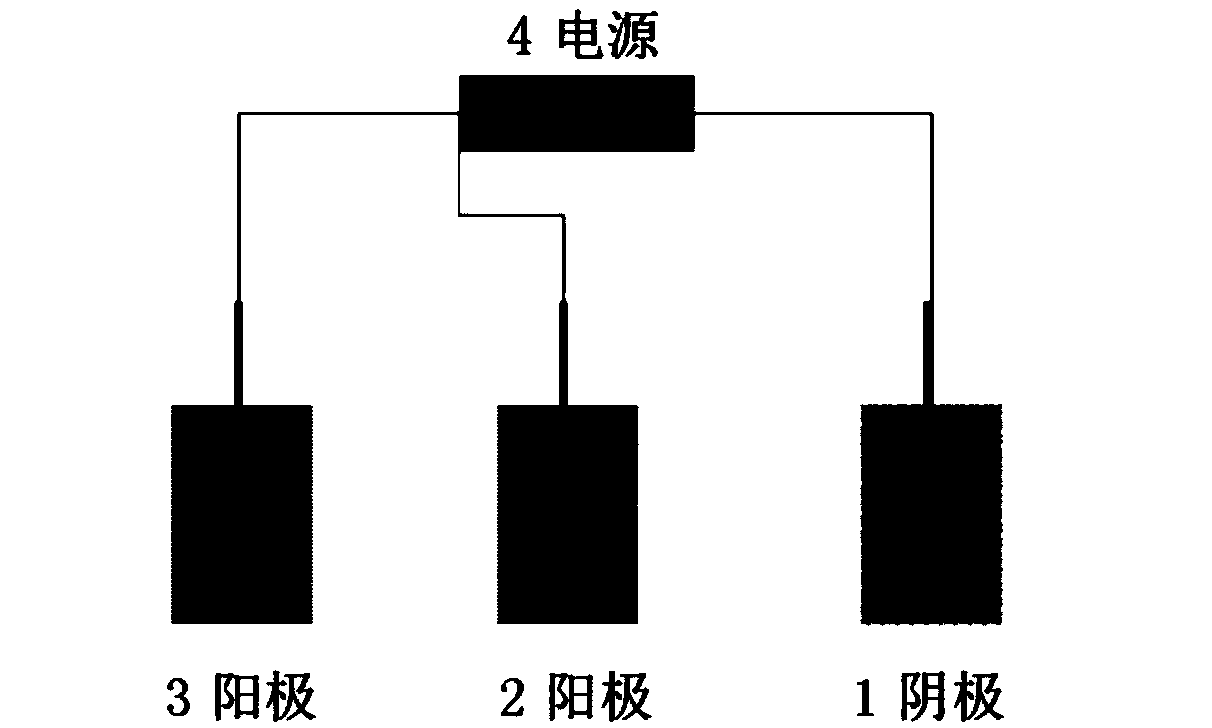

[0030] (1) The effective volume of the reactor is 1.8L, and the aspect ratio is 15:1.

[0031] (2) The water intake formula is as follows:

[0032] Acetate concentration 1.0g / L; 1ml / L vitamin solution and 1ml / L trace element solution, 50mM phosphate buffer solution (pH 7.0): concentration of main components of phosphate buffer solution: 11.55g / L dihydrogen phosphate dodecahydrate Sodium, 2.77g / L sodium dihydrogen phosphate dihydrate, 0.31g / L ammonium chloride, 0.13g / L potassium chloride; concentration of main components of vitamin solution: vitamin H, 0.2g / L, folic acid, 0.2g / L, Vitamin B6, 1g / L, Riboflavin, 0.5g / L, Vitamin B1, 0.5g / L, Niacin, 0.5g / L, Pantothenic Acid, 0.5g / L, B-12, 0.01g / L, P- Aminobenzoic acid, 0.5g / L, lipoic acid, 0.5g / L.

[0033] The main component concentration of trace element solution is: MgSO 4 3g / L, MnSO 4 ·H 2 O 0.5g / L, NaCl 1g / L, FeSO 4 ·7H 2 O 0.1g / L, CaCl 2 2H 2 O 0.1g / L, CoCl 2 ·6H 2 O 0.1g / L, ZnCl 2

[0034] 0.13g / L, CuSO 4 ·5H 2...

Embodiment 2

[0044] (1) The effective volume of the reactor is 1.8L, and the aspect ratio is 15:1.

[0045] (2) The water intake formula is as follows:

[0046] Acetate concentration 1.2g / L; 1ml / L vitamin solution and 1.5ml / L trace element solution, 60mM phosphate buffer solution (pH 7.0): concentration of main components of phosphate buffer solution: 12.3g / L hydrogen phosphate dodecahydrate Disodium, 2.95g / L sodium dihydrogen phosphate dihydrate, 0.5g / L ammonium chloride, 0.25g / L potassium chloride; main component concentration of vitamin solution vitamin H, 0.3g / L, folic acid, 0.3g / L, Vitamin B6, 1.2g / L, riboflavin, 0.6g / L, vitamin B1, 0.6g / L, niacin, 0.6g / L, pantothenic acid, 0.6g / L, B-12, 0.03g / L, P -Aminobenzoic acid, 0.6g / L, lipoic acid, 0.6g / L.

[0047] The concentration of the main components of the trace element solution includes MgSO 4 3.5g / L, MnSO 4 ·H 2 O 0.6g / L, NaCl

[0048] 1.2g / L, FeSO 4 ·7H 2 O 0.2g / L, CaCl 2 2H 2 O 0.2g / L, CoCl 2 ·6H 2 O 0.2g / L, ZnCl 2 0.25g...

Embodiment 3

[0057] For the starting effect test of embodiment 2:

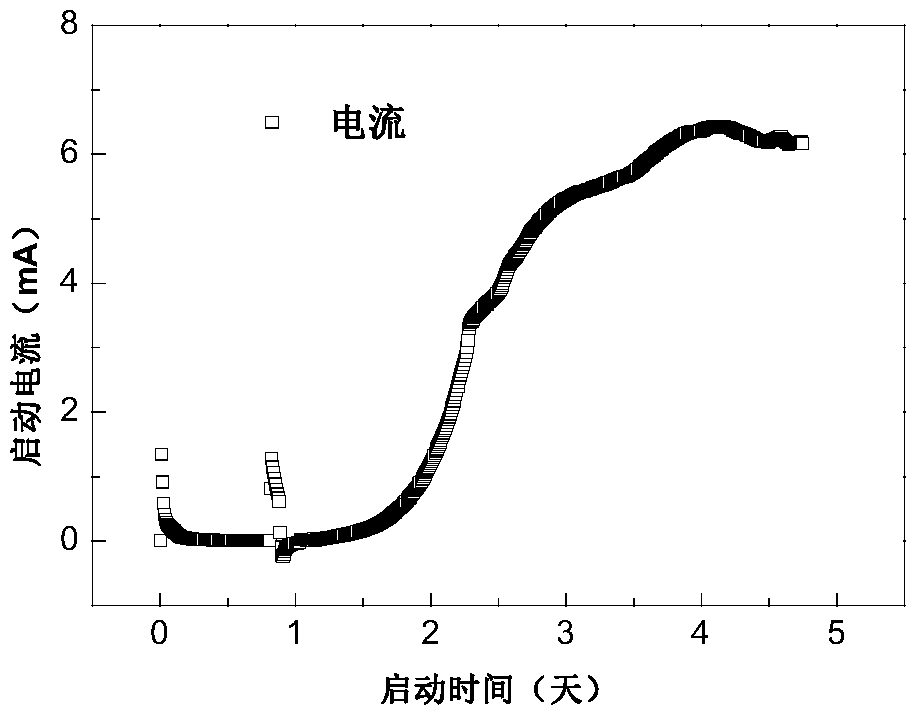

[0058] (1) if figure 2 As shown, the current fluctuated at the beginning of the water intake, and then stabilized. When the dissolved oxygen in the water increased from 2mg / L to 4mg / L on the second day, the current fluctuated, then stabilized, and increased steadily, and the increase was relatively slow. It began to increase rapidly on the second day, reached the maximum at 6.4mA on the sixth day, and then began to stabilize. After the fifth day, the current basically maintained at the level of 6mA.

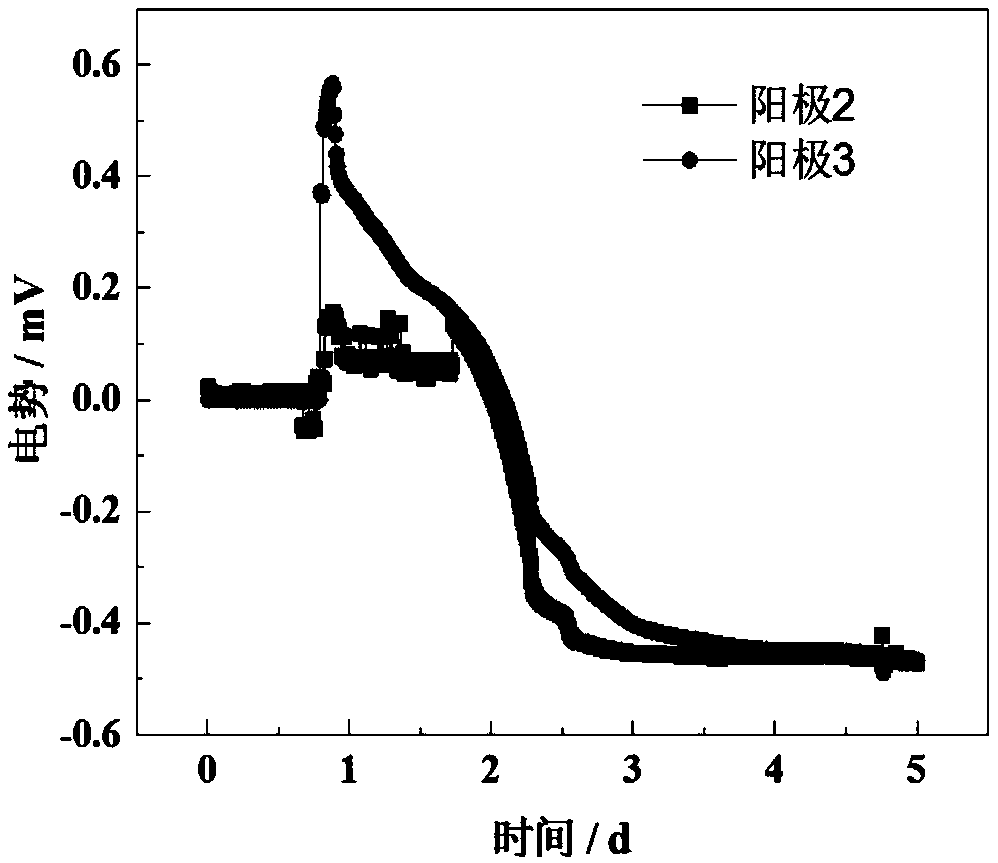

[0059] (2) by image 3 It can be seen that the two anode potentials drop rapidly during the start-up period, from 0mV to -0.5mV (vs Ag / AgCl) respectively during the start-up period.

[0060] (3) According to Figure 4 It can be seen that after the startup is stable, the COD concentration of the influent water is 1000mg / L, the effluent water is about 600mg / L, and the removal rate is 40%. After testing, the anode coulombic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com