Preparation method of plant-based fresh-keeping film

A plastic wrap, plant-based technology, applied in the preservation of food ingredients as anti-microbial, food science, food ingredients containing natural extracts, etc. Oxidative effect, cholesterol lowering, antiseptic and bacteriostatic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

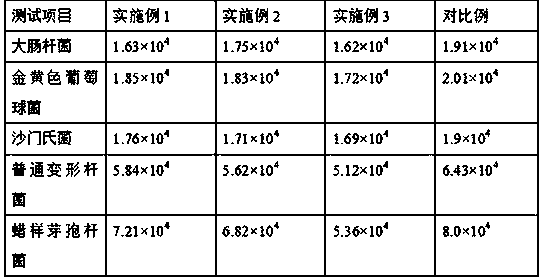

Examples

preparation example Construction

[0031] A preparation method of plant-based plastic wrap, comprising the steps of:

[0032] (1) Mix beet meal and solvent A according to the mass ratio of 1:20~30, stir magnetically at 400~600r / min for 30~50min, let stand for 3~6h, filter, and take the filter residue and dry it in an oven at 60~75℃ until If the water content is less than 5%, pretreated sugar beet meal is obtained. In a water bath at 50-75°C, polyethylene glycol, glycerol, and silicotungstic acid are mixed at a mass ratio of 5:1-2:0.01 to obtain a mixed solution. Add the pretreated sugar beet meal with 25-50% of the mixed liquid to the mixed solution, and mix it with 300W microwave treatment for 10-15 minutes to obtain the processed sugar beet meal, which is set aside;

[0033] (2) Mix radish red pigment and solvent B according to the mass ratio of 1:20~40, stir magnetically at 350~500r / min for 30~50min, pass through a microporous filter membrane of 0.18~0.22μm, and perform ultrafiltration at 0.2~0.5MPa. Filter...

Embodiment 1

[0038] Adjuvant: Mix paraffin and epichlorohydrin at a mass ratio of 1:4 to obtain the adjuvant.

[0039] Solvent A: Take PBS buffer, NH at a mass ratio of 5:1 4 Cl mixed to obtain solvent A.

[0040] Solvent B: Mix 10% NaOH solution and sodium bicarbonate at a mass ratio of 12:1 to obtain solvent B.

[0041]Plasticizer: Dibutyl phthalate.

[0042] Initiator: sodium persulfate.

[0043] Defoaming agent: Mix polydimethylsiloxane and microcrystalline paraffin at a mass ratio of 5:1 to obtain a defoaming agent.

[0044] Emulsifier: Mix rosin lecithin and soybean lecithin at a mass ratio of 5:1 to obtain an emulsifier.

[0045] Tannin: Arbutus tannin.

[0046] Auxiliary: mix sodium citrate, sodium alginate and carrageenan at a mass ratio of 3:1:1 to obtain the adjuvant.

[0047] A preparation method of plant-based plastic wrap, comprising the steps of:

[0048] (1) Mix sugar beet meal and solvent A according to the mass ratio of 1:20, stir magnetically at 400r / min for 30min...

Embodiment 2

[0054] Adjuvant: Mix paraffin and epichlorohydrin at a mass ratio of 1:7 to obtain the adjuvant.

[0055] Solvent A: Take PBS buffer, NH at a mass ratio of 5:2 4 Cl mixed to obtain solvent A.

[0056] Solvent B: Mix 10% NaOH solution and sodium bicarbonate at a mass ratio of 18:1 to obtain solvent B.

[0057] Plasticizer: Dioctyl phthalate.

[0058] Initiator: potassium persulfate.

[0059] Defoamer: Mix polydimethylsiloxane and microcrystalline paraffin at a mass ratio of 5:2 to obtain a defoamer.

[0060] Emulsifier: Mix rosin lecithin and soybean lecithin at a mass ratio of 5:2 to obtain an emulsifier.

[0061] Tannins: Grape tannins.

[0062] Auxiliary: Mix sodium citrate, sodium alginate and carrageenan at a mass ratio of 3:2:1 to obtain the adjuvant.

[0063] A preparation method of plant-based plastic wrap, comprising the steps of:

[0064] (1) Mix sugar beet pulp and solvent A at a mass ratio of 1:30, stir magnetically at 600r / min for 50min, let it stand for 6h,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com