Method of preparing ferrotitanium alloy powder by adopting ferrovanadium slag and vanadium-titanium magnetite tailings

A technology of vanadium-titanium magnet and iron-titanium alloy, which is applied in the direction of improving process efficiency and can solve the problems of large industrial demand and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

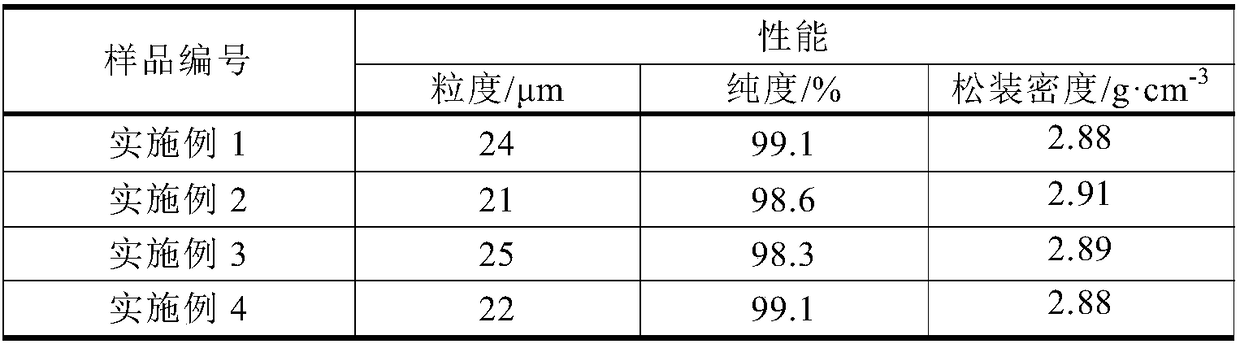

Examples

preparation example Construction

[0019] A kind of preparation method of iron-titanium alloy powder material of the present invention comprises the following steps:

[0020] (1) According to (89.8~95): (1.6~3.3): (3.4~6.9) ratio weighed alum slag, graphite powder and calcium carbonate powder, placed in a stirring ball mill with a speed of 260~350 rpm, The ball-to-material ratio is 3:1, ball milled for 15 to 25 hours, and uniformly refined to obtain micron-sized mixed powder;

[0021] (2) Mix vanadium-titanium magnet tailings, sodium oxide, and calcium fluoride according to the ratio of (88.3-92.2): (5.4-8.3): (2.4-5.9), pre-fire in a sintering furnace at 550-670°C, and keep warm for 4 ~6 hours.

[0022] (3) Put the two mixed powders into a disc granulator for granulation at a speed of 11-25 r / min, the pelletizing agent is PVA aqueous solution, and then place it in a blast dryer at 320°C for 6-9 hours to degrease.

[0023] (4) Send the degreased powder particles into an atmosphere furnace for reduction and si...

Embodiment 1

[0026] (1) According to the ratio of 92.3:3.3:4.4, weigh the alum slag, graphite powder and calcium carbonate powder, place them in the stirring ball mill, the speed is 280 rpm, the ratio of ball to material is 3:1, ball mill for 15 hours, and carry out uniform fine grinding. Chemical treatment to obtain micron-sized mixed powder;

[0027] (2) Mix vanadium-titanium magnet tailings, sodium oxide, and calcium fluoride at a ratio of 88.6:8.3:3.1, pre-sinter in a sintering furnace at 670°C, and keep warm for 5 hours.

[0028] (3) Put the two mixed powders into a disc granulator for granulation at a speed of 19 rpm. The pelleting agent is a PVA aqueous solution, and then place them in a blast dryer at 320° C. for degreasing for 6 hours.

[0029] (4) Send the degreased powder particles into an atmosphere furnace for reduction and sintering at 890° C. for 2 hours, and finally crush and sieve to obtain the iron-titanium alloy powder material.

Embodiment 2

[0031] (1) According to the ratio of 93.5:2.1:4.4, weigh the alum slag, graphite powder and calcium carbonate powder, place them in the stirring ball mill, the speed is 350 rpm, the ratio of ball to material is 3:1, ball mill for 15 hours, and carry out uniform fine grinding. Chemical treatment to obtain micron-sized mixed powder;

[0032] (2) Mix vanadium-titanium magnet tailings, sodium oxide, and calcium fluoride at a ratio of 90.4:6.1:3.5, pre-sinter in a sintering furnace at 620°C, and keep warm for 6 hours.

[0033] (3) Put the two kinds of mixed powders into a disc granulator for granulation at a speed of 21 rpm, and the pelletizing agent is PVA aqueous solution, and then put them in a blast dryer at 320° C. for 7 hours for degreasing.

[0034] (4) Send the degreased powder particles into an atmosphere furnace for reduction and sintering at 900° C. for 4 hours, and finally crush and sieve to obtain the iron-titanium alloy powder material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com