Graphite-phase carbon nitride nanosheet-based composite photocatalytic material as well as preparation method and application thereof

A graphitic carbon nitride and composite photocatalysis technology, which is applied in the field of photocatalytic materials, can solve the problems of easy agglomeration, uneven distribution, uneven mechanical mixing, etc., and achieves mild reaction conditions, simple preparation process and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The invention provides a preparation method of a graphite-phase carbon nitride nanosheet-based composite photocatalytic material, comprising the following steps:

[0028] Provide graphite phase carbon nitride;

[0029] Mixing the graphitic carbon nitride with an inorganic alkaline solution to obtain a suspension;

[0030] The metal salt is added dropwise into the suspension, followed by a hydrolysis reaction to obtain a hydrolysis reaction product, and the metal salt is zinc nitrate, zinc acetate, zinc chloride, cerium nitrate, cerium acetate, ferric chloride, ferric nitrate, nitric acid Cobalt, titanium tetrachloride or tetrabutyl titanate;

[0031] The hydrolysis reaction product is sequentially washed and vacuum-dried to obtain a graphite-phase carbon nitride nanosheet-based composite photocatalytic material precursor;

[0032] Calcining the graphite-phase carbon nitride nanosheet-based composite photocatalytic material precursor to obtain the graphite-phase carbon...

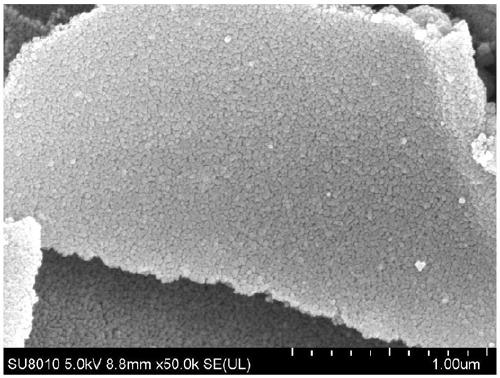

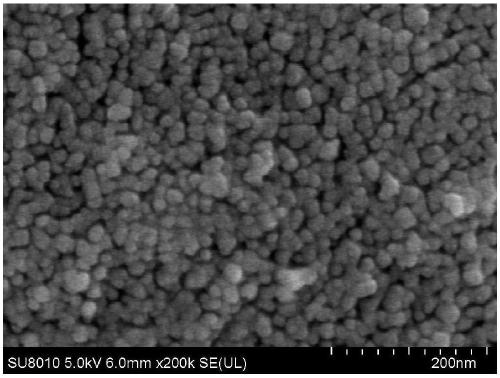

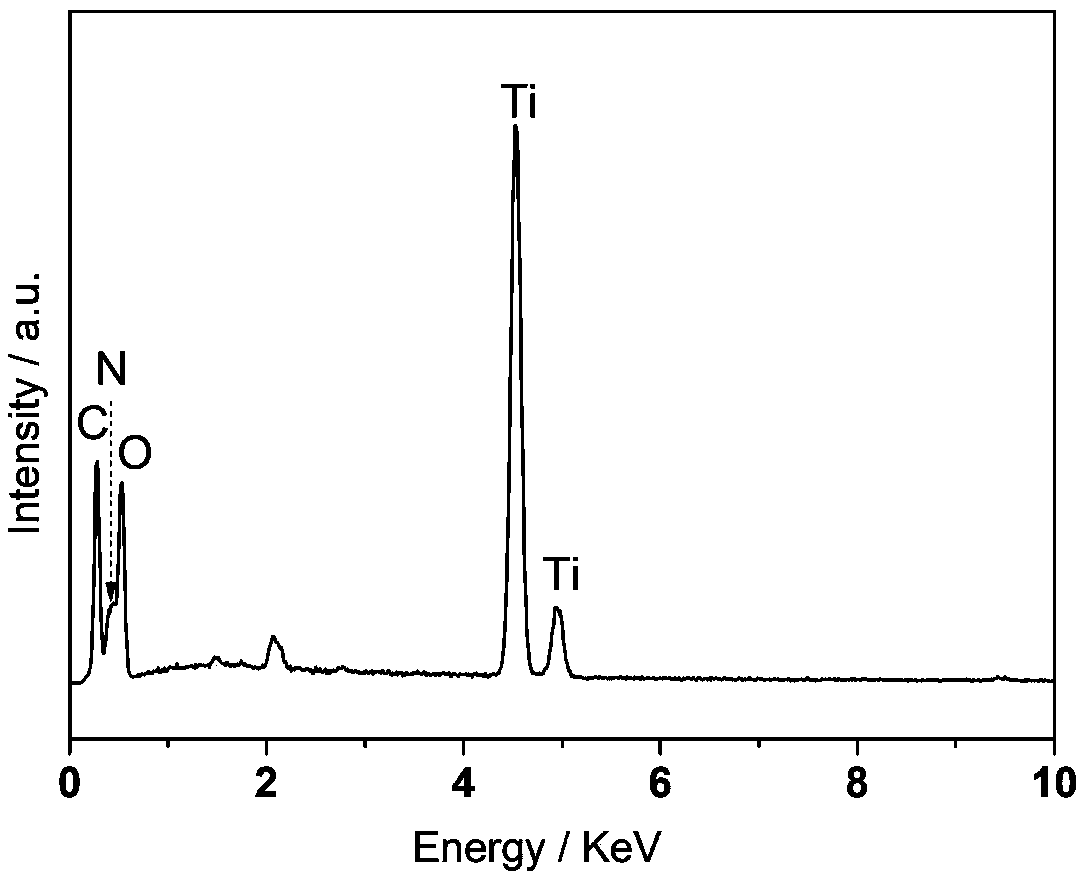

Embodiment 1

[0053] Put thiourea into a ceramic crucible and cover it, place it in a muffle furnace for calcination, heat it up to 600°C at a heating rate of 15°C / min and keep it for 4h to obtain a yellow powder sample, namely graphite phase carbon nitride. Add 1 g of graphitic carbon nitride into 100 mL of 6 mol / L potassium hydroxide solution, ultrasonically disperse, and gradually drop into 50 wt % ammonia solution until the pH is 13. Then, 0.5 g of titanium tetrachloride was gradually added while stirring until the precipitate appeared and kept for 0.5 h, washed with ethanol and deionized water several times respectively, and then vacuum-dried at 90° C. for 8 h. The dry precursor was calcined at 500°C for 2h, and the heating rate was 5°C / min, then the desired graphite-phase carbon nitride nanosheet-based composite photocatalytic material, that is, graphite-phase carbon nitride nanosheet / titanium dioxide composite Photocatalytic materials (two-dimensional carbon nitride / titanium dioxide)...

Embodiment 2

[0057] Put cyanuric chloride into a ceramic crucible and cover it, place it in a muffle furnace for calcination, heat it up to 560°C at a heating rate of 10°C / min and keep it warm for 5 hours to obtain a yellow powder sample, that is, graphite phase carbon nitride . Add 1 g of graphitic carbon nitride into 100 mL of 6 mol / L potassium hydroxide solution, ultrasonically disperse, and gradually drop into 50 wt % ammonia solution until the pH is 12. Then, 1 g of tetrabutyl titanate was gradually added while stirring, until the precipitate appeared and kept for 0.7 h, washed with ethanol and deionized water several times, and then vacuum-dried at 100° C. for 10 h. The dried precursor was calcined at 520°C for 4h with a heating rate of 15°C / min to obtain the desired graphitic carbon nitride nanosheet / titanium dioxide composite photocatalytic material. Titanium dioxide is evenly distributed on the surface of graphite phase carbon nitride nanosheets with layered structure, and the pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com