Preparation method of hydrogel

A hydrogel and aqueous solution technology, which is applied in the field of gel material synthesis, can solve the problems of lack of in vivo drug delivery characteristics, less β-CD, and inapplicability, and achieve good biocompatibility, fast cross-linking speed, and improved Effects of mechanical strength and viscoelasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Preparation of cellulose nanofibril membrane:

[0026] Take an appropriate amount of TEMPO oxidized cellulose nanofibrils and add them to water, stir rapidly at 40°C until they are completely dissolved, then add glycerin and continue to stir rapidly at 40°C until the solution is uniform and transparent, then the solution is subjected to centrifugal defoaming and ultrasonic defoaming treatment, degassing The soaked solution is dried in an oven at 55°C for 6-12 hours to obtain a cellulose nanofibril film.

[0027] The parts by mass of each raw material added in the reaction system are: 1.5 parts of TEMPO oxidized cellulose nanofibrils, 6 parts of glycerin, and the balance of water.

[0028] 2. Preparation of hydrogel:

[0029] Dissolve the water-soluble cationic β-CD polymer in water to prepare a solution with a concentration of 20%, and then take an appropriate amount of Ag-NH 2 NPs (prepared by referring to the methods described in the aforementioned literature 1 a...

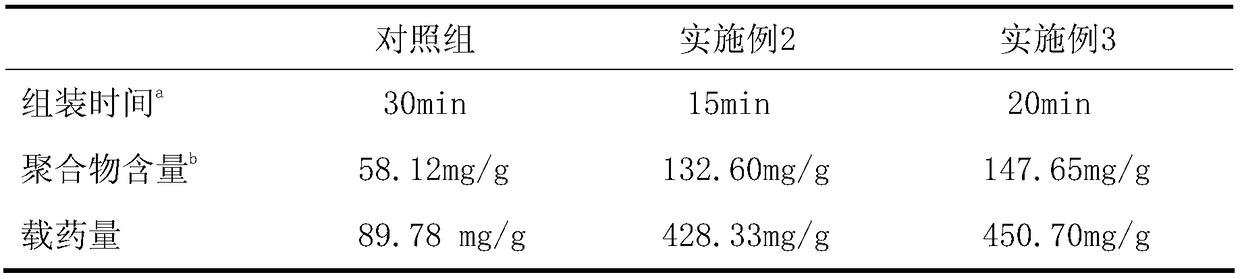

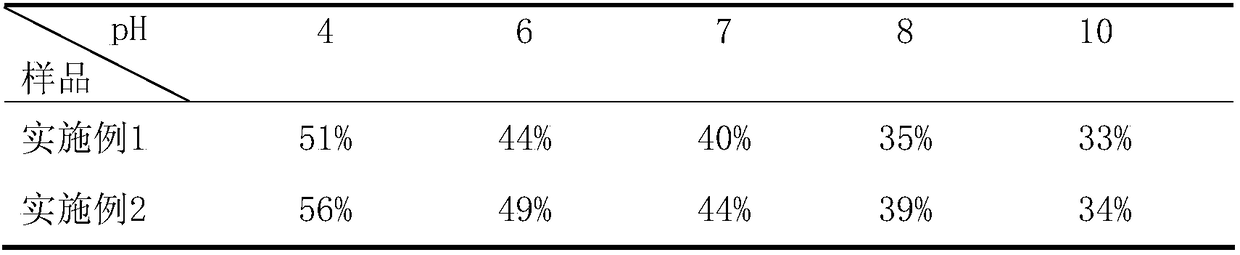

Embodiment 2

[0031] 1. Preparation of cellulose nanofibril membrane:

[0032] Take an appropriate amount of TEMPO oxidized cellulose nanofibrils and add them to water, stir rapidly at 40°C until they are completely dissolved, then add glycerin and continue to stir rapidly at 40°C until the solution is uniform and transparent, then the solution is subjected to centrifugal defoaming and ultrasonic defoaming treatment, degassing The soaked solution was dried in an oven at 55° C. for 10 h to obtain a cellulose nanofibril film.

[0033] The mass parts of each raw material added in the reaction system are: 2 parts of TEMPO oxidized cellulose nanofibrils, 7 parts of glycerin, and the balance of water.

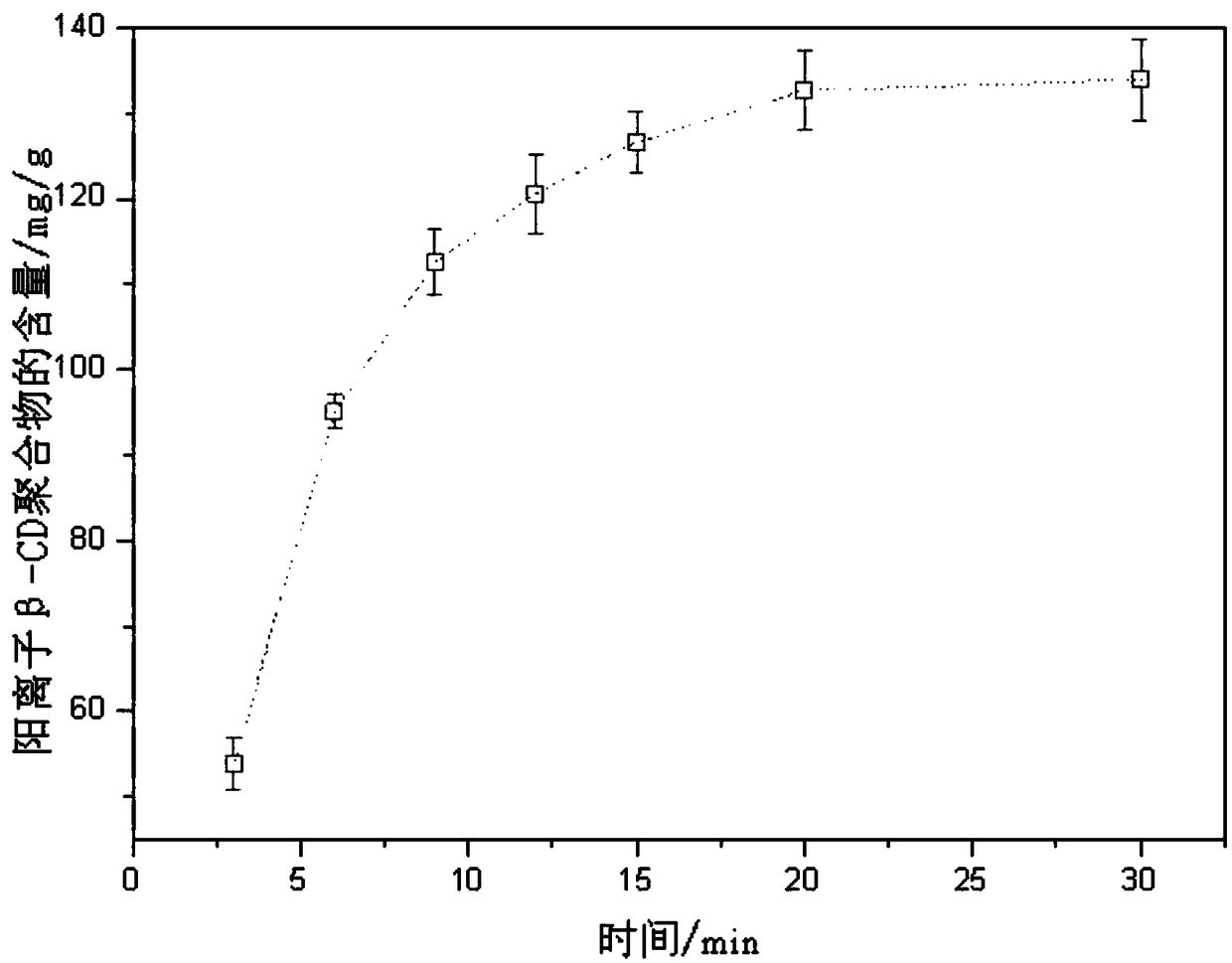

[0034] 2. Preparation of water-soluble cationic β-CD polymer:

[0035] (1) Add an appropriate amount of β-CD into NaOH solution with a concentration of 220g / L, stir at 60°C until completely dissolved, then add 2,3-epoxypropyltrimethylammonium chloride solution with a concentration of 900g / L, Epi...

Embodiment 3

[0044] 1. Preparation of cellulose nanofibril membrane:

[0045] Take an appropriate amount of TEMPO oxidized cellulose nanofibrils and add them to water, stir rapidly at 40°C until they are completely dissolved, then add glycerin and continue to stir rapidly at 40°C until the solution is uniform and transparent, then the solution is subjected to centrifugal defoaming and ultrasonic defoaming treatment, degassing The soaked solution was dried in an oven at 55° C. for 10 h to obtain a cellulose nanofibril film.

[0046] The mass parts of each raw material added in the reaction system are: 1 part of TEMPO oxidized cellulose nanofibrils, 5 parts of glycerin, and the balance of water.

[0047] 2. Preparation of water-soluble cationic β-CD polymer: the method is the same as in Example 2.

[0048] 3. Preparation of hydrogel:

[0049] Dissolve the water-soluble cationic β-CD polymer prepared in step 2 in water to prepare a solution with a concentration of 30%, and then take an appr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Charge density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com