Method of preparing aluminum-titanium alloy plating through electrodeposition in organic solvent system at room temperature

An organic solvent, aluminum-titanium alloy technology, which is applied in the field of preparing aluminum-titanium alloy coatings by electrodeposition of organic solvent systems at room temperature, can solve problems such as affecting the quality of coatings and can only be carried out in non-aqueous electrolyte systems, and achieves increased titanium ion concentration, The effect of uniform particle size and pure aluminum-titanium alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

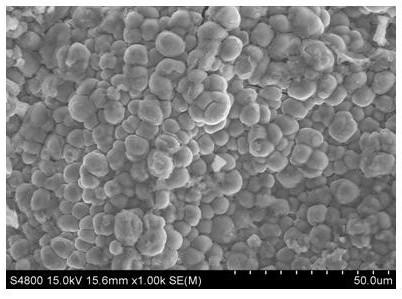

Image

Examples

Embodiment 1

[0020] (1) Preparation of plating solution

[0021] In a closed glove box filled with argon, weigh 8.01 g of anhydrous aluminum chloride and 0.57 g of lithium aluminum hydride; first, slowly add 40 ml of benzene to the anhydrous aluminum chloride and lithium aluminum hydride; then use a magnetic force Stir it with a stirrer, and slowly add 10 ml of tetrahydrofuran solution to anhydrous aluminum chloride and lithium aluminum hydride under the condition of ice bath, this process emits a lot of heat; Measure 0.95 g of anhydrous titanium tetrachloride with a black needle; under ice bath conditions, in a closed environment, slowly add anhydrous titanium tetrachloride to anhydrous aluminum chloride and lithium aluminum hydride. It was mixed and stirred on a magnetic stirrer for 3 hours in an ice bath.

[0022] (2) Copper substrate treatment

[0023] The copper sheet is polished with 400, 800, 1200 mesh sandpaper in turn, and then chemical degreasing is performed to remove the oil ...

Embodiment 2

[0027] (1) Preparation of plating solution

[0028] In a closed glove box filled with argon, weigh 8.01 g of anhydrous aluminum chloride and 0.57 g of lithium aluminum hydride; first, slowly add 40 ml of benzene to the anhydrous aluminum chloride and lithium aluminum hydride; then use a magnetic force Stir it with a stirrer, and slowly add 10 ml of tetrahydrofuran solution to anhydrous aluminum chloride and lithium aluminum hydride under the condition of ice bath, this process emits a lot of heat; Measure 1.45 grams of anhydrous titanium tetrachloride with a black needle; under ice bath conditions, in a closed environment, slowly add anhydrous titanium tetrachloride to anhydrous aluminum chloride and lithium aluminum hydride. It was mixed and stirred on a magnetic stirrer for 3 hours in an ice bath.

[0029] (2) Copper substrate treatment

[0030] The copper sheet is polished with 400, 800, 1200 mesh sandpaper in turn, and then chemical degreasing is performed to remove the ...

Embodiment 3

[0034] (1) Preparation of plating solution

[0035] In a closed glove box filled with argon, weigh 8.01 g of anhydrous aluminum chloride and 0.57 g of lithium aluminum hydride; first, slowly add 40 ml of benzene to the anhydrous aluminum chloride and lithium aluminum hydride; then use a magnetic force Stir it with a stirrer, and slowly add 10 ml of tetrahydrofuran solution to anhydrous aluminum chloride and lithium aluminum hydride under the condition of ice bath, this process emits a lot of heat; Measure 2.95 grams of anhydrous titanium tetrachloride with a black needle; under ice bath conditions, in a closed environment, slowly add anhydrous titanium tetrachloride to anhydrous aluminum chloride and lithium aluminum hydride. It was mixed and stirred on a magnetic stirrer for 3 hours in an ice bath.

[0036] (2) Copper substrate treatment

[0037] The copper sheet is polished with 400, 800, 1200 mesh sandpaper in turn, and then chemical degreasing is performed to remove the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com