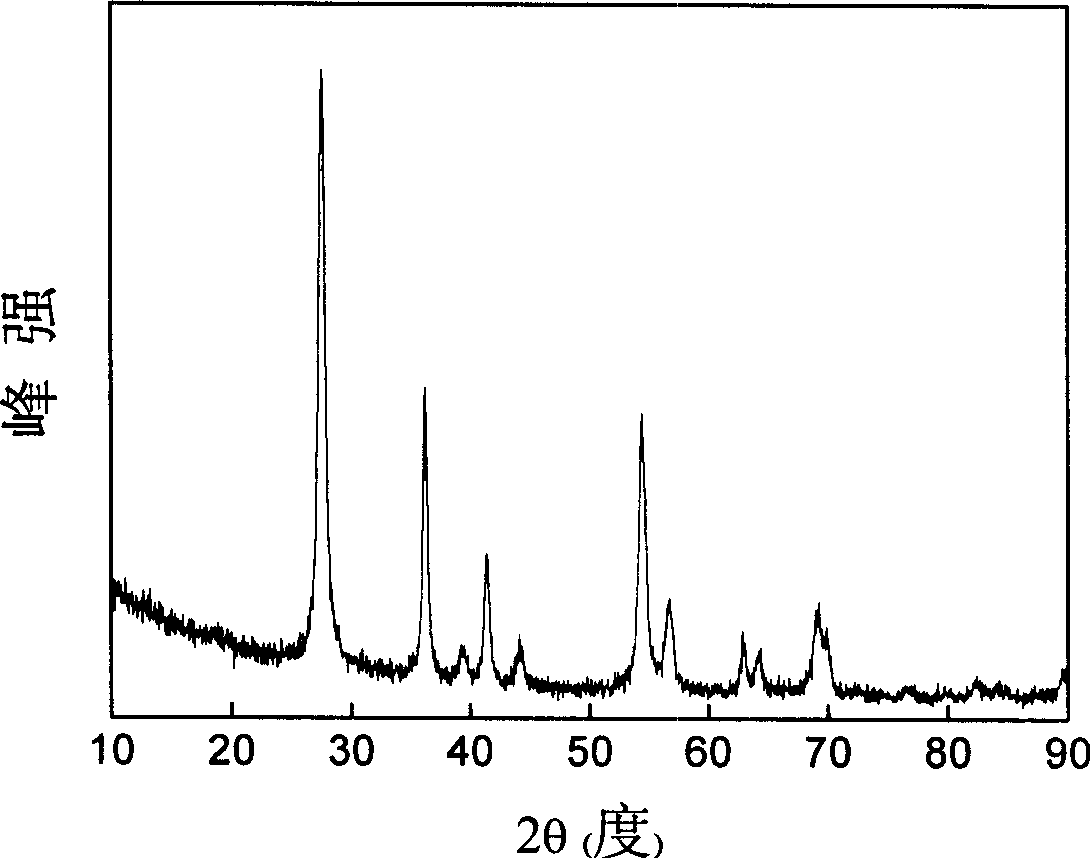

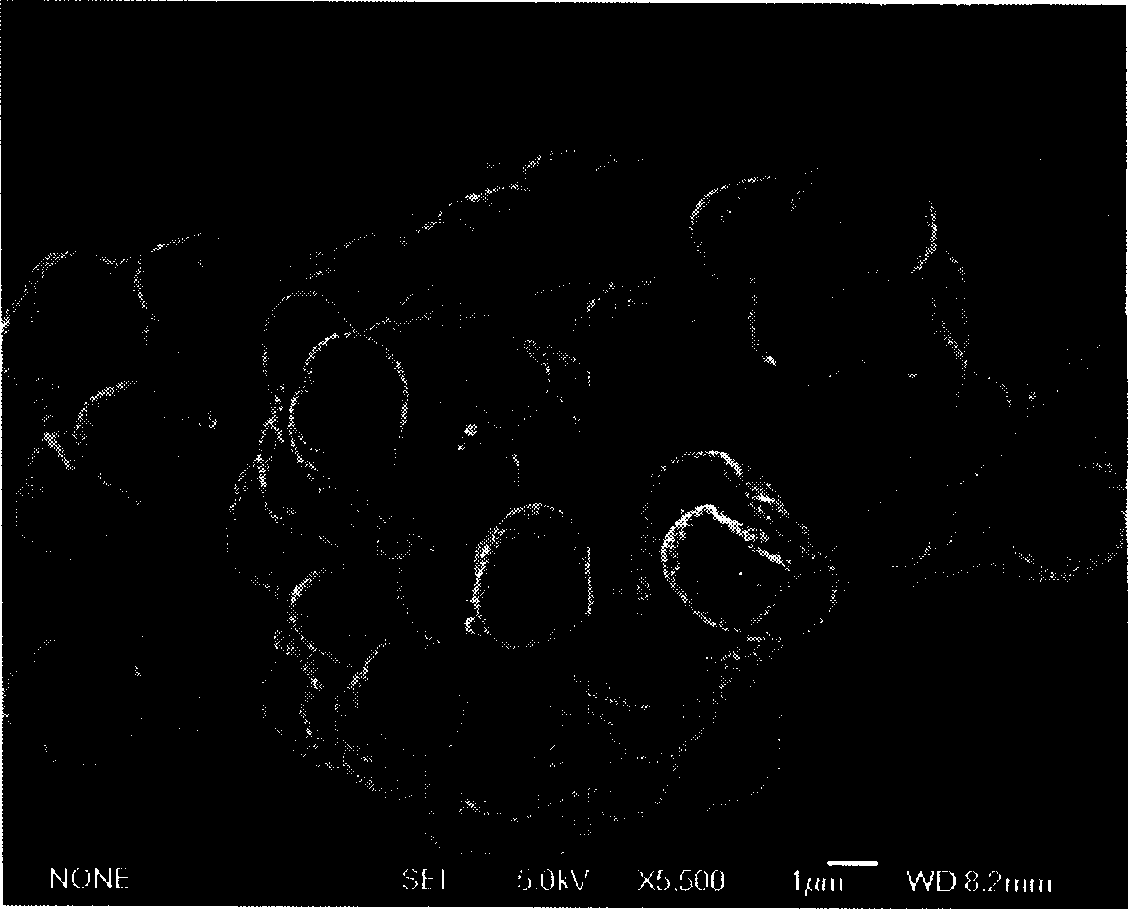

Clean method for preparing rutile-type titanium dioxide from high-titanium slag by hydrothermal method

A titanium dioxide and clean production technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of high energy consumption, complex equipment and serious pollution in the production process, so as to help improve product quality, reduce energy consumption, and greatly reduce energy consumption. economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Circulate the 500g / L NaOH alkali solution back to the reactor, add 200 mesh high-titanium slag and mix evenly under stirring. The mass ratio of NaOH to high-titanium slag is 0.5:1, and hydrothermally react at 180°C for 0.5 hours to obtain a hydrothermal reaction The product, the conversion rate of high titanium slag is 100%. Filtrating the reaction product to obtain a crude product containing sodium titanate and a concentrated solution of sodium hydroxide, the concentrated solution of sodium hydroxide can be used in the above steps for hydrothermal reaction after evaporation and dehydration;

[0028] The crude product of sodium titanate was washed twice with recycled water, and the solid-to-liquid mass ratio of each wash was 1:40. The sodium titanate product obtained after filtration was added to the recycled sulfuric acid solution to dissolve it completely, and the solid-to-liquid ratio was 1:200, and then add sodium sulfite to the solution. Finally, the solution was ...

Embodiment 2

[0030] Circulate the 200g / L NaOH alkali solution back to the reactor, add 300 mesh high-titanium slag and mix evenly under stirring. The mass ratio of NaOH to high-titanium slag is 5:1, and hydrothermally react at 280°C for 10 hours to obtain a hydrothermal reaction The product, the conversion rate of high titanium slag is 99.0%. Filtrating the reaction product to obtain a crude product containing sodium titanate and a concentrated solution of sodium hydroxide, the concentrated solution of sodium hydroxide can be used in the above steps for hydrothermal reaction after evaporation and dehydration;

[0031] The crude product of sodium titanate was washed twice with recycled water, and the solid-to-liquid mass ratio of each washing was 1:10. The sodium titanate product obtained after filtration was added to the recycled hydrochloric acid solution, and the solid-to-liquid ratio was 1:50, and then Add iron filings to this mixture. Finally, the mixed solution was hydrolyzed at 150°...

Embodiment 3

[0033] Circulate the 320g / L NaOH alkali solution back to the reactor, add 250 mesh high-titanium slag and mix evenly under stirring. The mass ratio of NaOH to high-titanium slag is 3.8:1, and hydrothermally react at 240°C for 4 hours to obtain a hydrothermal reaction The product, the conversion rate of high titanium slag is 99.4%. Filtrating the reaction product to obtain a crude product containing sodium titanate and a concentrated solution of sodium hydroxide, the concentrated solution of sodium hydroxide can be used in the above steps for hydrothermal reaction after evaporation and dehydration;

[0034] The crude product of sodium titanate was washed twice with recycled water, and the solid-to-liquid mass ratio of each wash was 1:20, and the sodium titanate product obtained after filtration was added to the recycled nitric acid solution, with a solid-to-liquid ratio of 1:100, and then Sodium thiosulfate was added to the mixture. Finally, the mixed solution was hydrolyzed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com