Control method for metal-slag reaction in sponge iron steelmaking process and device thereof

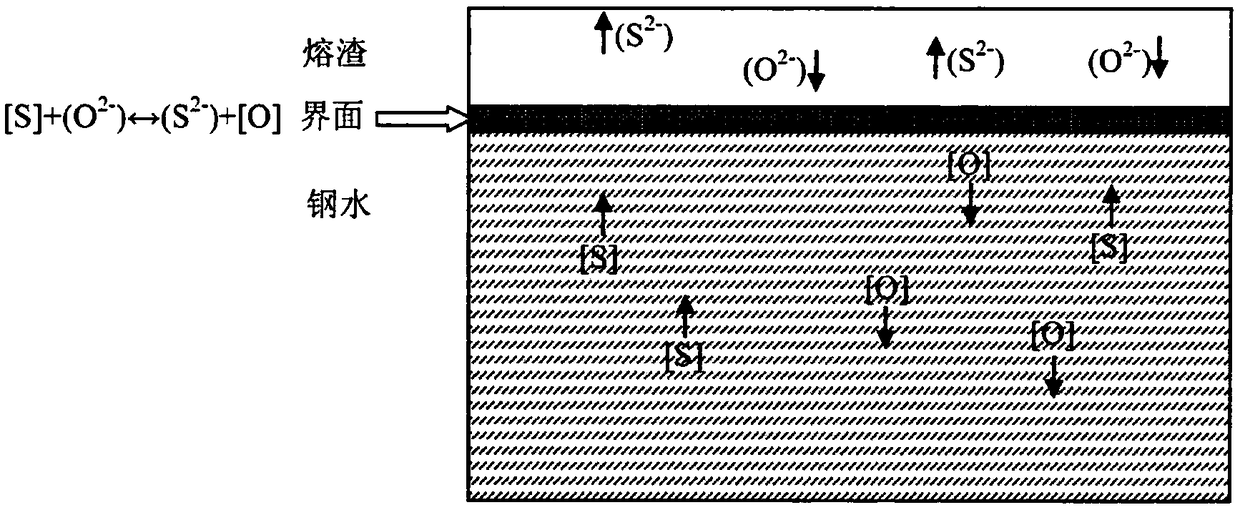

A technology of sponge iron and slag gold, which is applied to the improvement of process efficiency, electric furnace, furnace and other directions, can solve the problems of insufficient slag gold reaction, large electrode consumption and high production cost, and achieves favorable removal, quality improvement and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

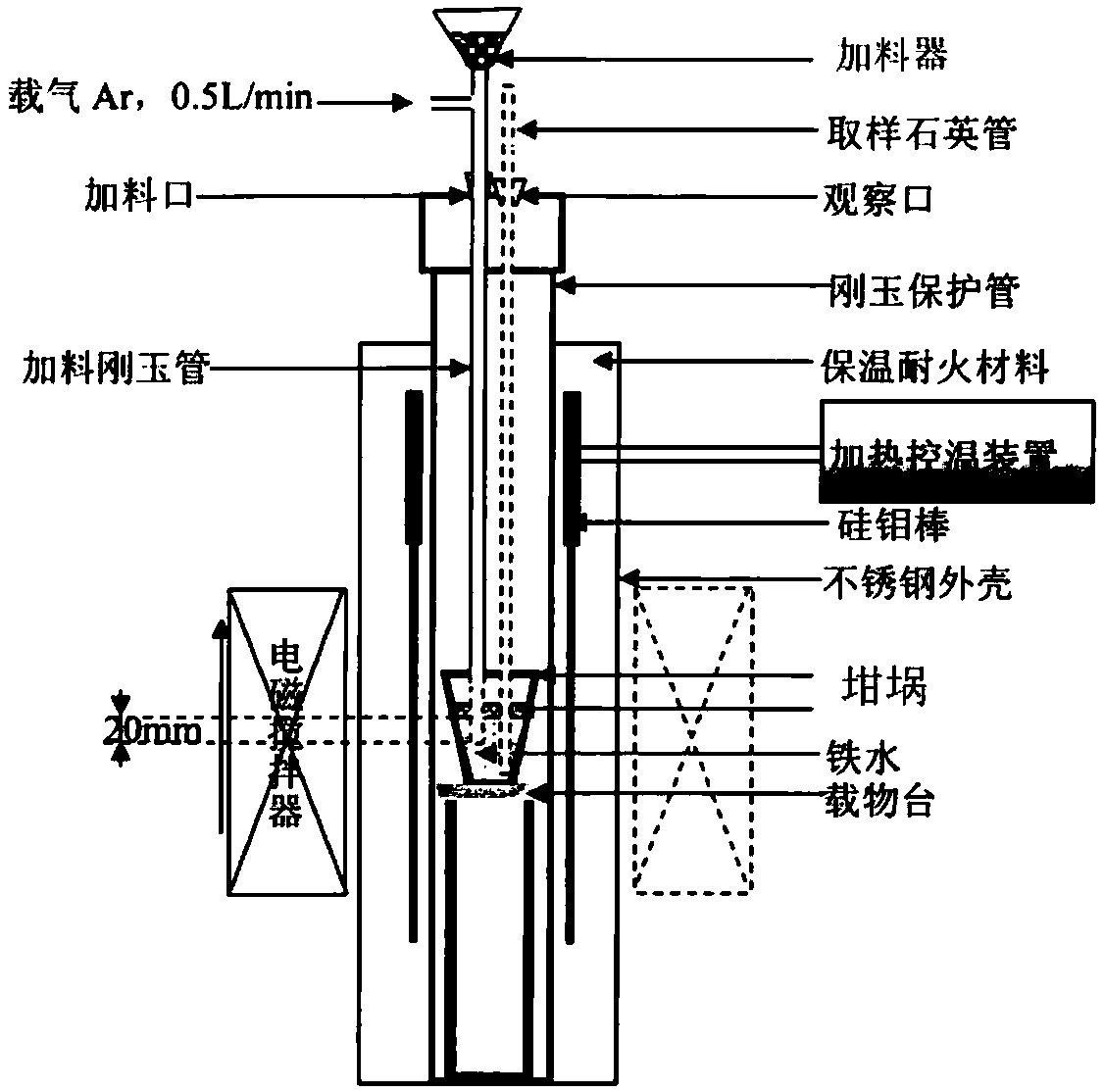

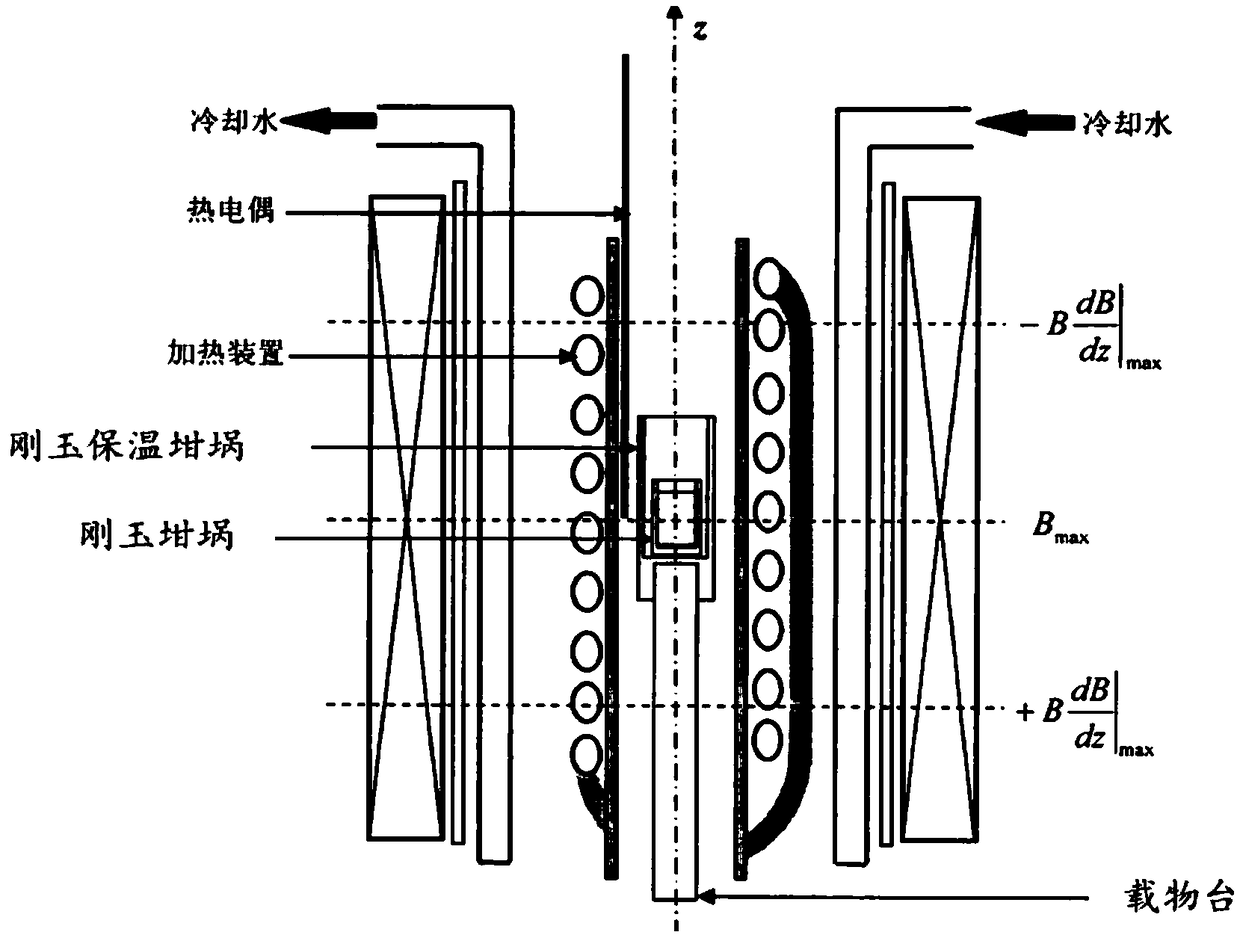

[0041] The sponge iron balls with ingredients such as Table 1 are ground to 200 mesh; figure 2 In the feeder in the feeder, the material is sent to the crucible through the feeder, vacuumed to make the vacuum degree in the corundum protection tube reach 1Pa, the vacuum system is closed, and then argon gas with a purity of 99.9% is introduced into the corundum protection tube to an atmospheric pressure, and then Then open the vacuum system to make the corundum protection tube vacuum up to 1Pa, then fill the argon with a purity of 99.9% to an atmospheric pressure, repeat twice, and finally maintain a slight positive pressure in the corundum tube, and keep the argon flow rate at 0.2L / min . Heat the silicon-molybdenum rod, keep it warm for 20 minutes after reaching the set temperature, stop heating, pass a 2Hz, 400A current to the electromagnetic stirrer, stir for 2 minutes, stop stirring, continue heating for 5 minutes, repeat twice, in the case of continuing heating, Pull down...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com