High-rigidity waterborne fluorocarbon paint

A water-based fluorocarbon, high-hardness technology, used in coatings, anti-corrosion coatings, fire-retardant coatings, etc., can solve problems such as poor pigment dispersion, and achieve the effect of good corrosion resistance, high hardness and tight bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

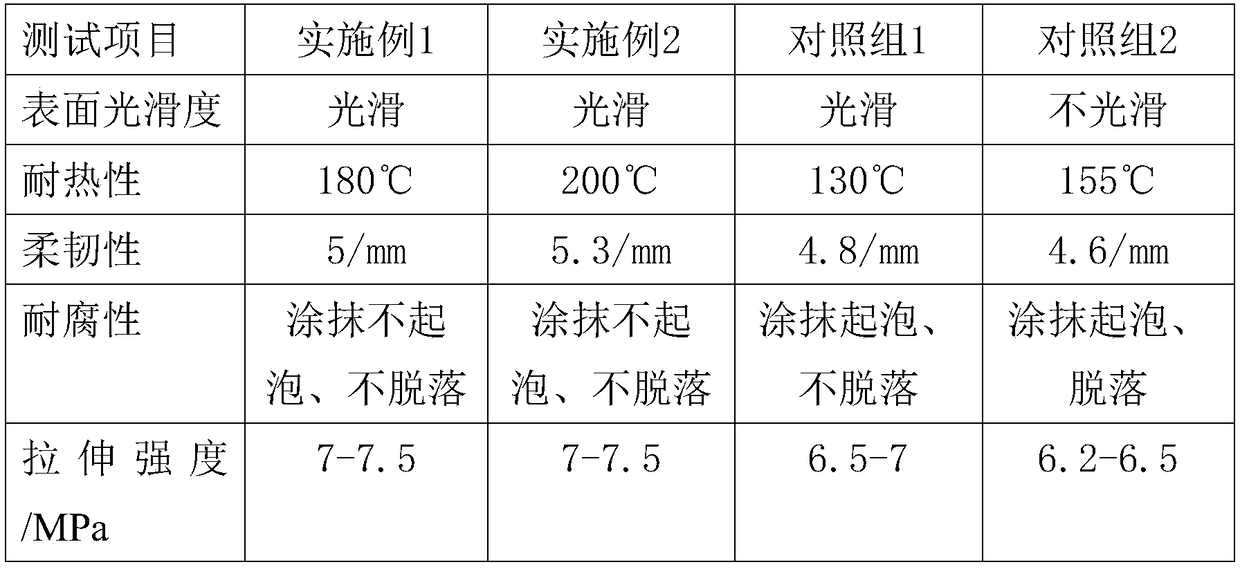

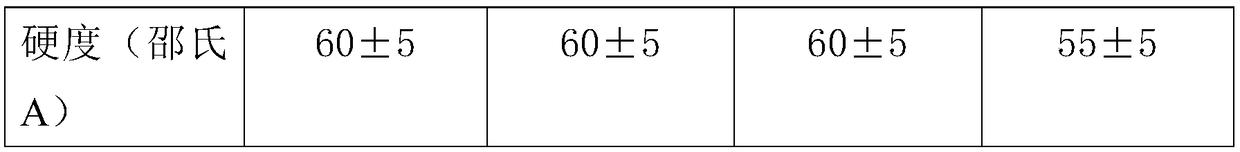

Examples

Embodiment 1

[0021] A high-hardness water-based fluorocarbon paint, made of the following raw materials in parts by weight: 40 parts of ultrafine polytetrafluoroethylene powder, 10 parts of modified ceramic micropowder, 10 parts of bamboo charcoal powder, 4 parts of expanded graphite powder, polyether silicone oil 2 parts, 10 parts of methyl glucose sesquistearate, 1 part of methyl cellulose, 1 part of titanium dioxide, 0.5 parts of melamine formaldehyde resin, 10 parts of glycerol, 80 parts of water.

[0022] Further, the modified ceramic micropowder is made of ceramic micropowder, activated carbon, and epoxy resin. The preparation method is: uniformly mix the ceramic micropowder and activated carbon, grind, and drop the ground mixture into three times the weight of Alcohol, after fully stirring and dissolving, mix with epoxy resin and stir evenly, microwave reflux treatment in a microwave processor at 2450MHz, power 700W for 5 minutes, after standing for 10 minutes, continue microwave tre...

Embodiment 2

[0030] A high-hardness water-based fluorocarbon paint, made of the following raw materials in parts by weight: 50 parts of ultrafine polytetrafluoroethylene powder, 15 parts of modified ceramic micropowder, 13 parts of bamboo charcoal powder, 5 parts of expanded graphite powder, polyether silicone oil 3 parts, 13 parts of methyl glucose sesquistearate, 2 parts of methyl cellulose, 2 parts of titanium oxide, 1.5 parts of melamine formaldehyde resin, 15 parts of glycerol, 100 parts of water.

[0031] Further, the modified ceramic micropowder is made of ceramic micropowder, activated carbon, and epoxy resin. The preparation method is: uniformly mix the ceramic micropowder and activated carbon, grind, and drop the ground mixture into three times the weight of Alcohol, after fully stirring and dissolving, mix with epoxy resin and stir evenly, microwave reflux treatment in a microwave processor at 2450MHz, power 700W for 5 minutes, after standing for 10 minutes, continue microwave tr...

Embodiment 3

[0039] A high-hardness water-based fluorocarbon paint, made of the following raw materials in parts by weight: 60 parts of ultrafine polytetrafluoroethylene powder, 20 parts of modified ceramic micropowder, 15 parts of bamboo charcoal powder, 6 parts of expanded graphite powder, polyether silicone oil 4 parts, 15 parts of methyl glucose sesquistearate, 3 parts of methyl cellulose, 3 parts of titanium oxide, 3 parts of melamine formaldehyde resin, 20 parts of glycerin, 120 parts of water.

[0040] Further, the modified ceramic micropowder is made of ceramic micropowder, activated carbon, and epoxy resin. The preparation method is: uniformly mix the ceramic micropowder and activated carbon, grind, and drop the ground mixture into three times the weight of Alcohol, after fully stirring and dissolving, mix with epoxy resin and stir evenly, microwave reflux treatment in a microwave processor at 2450MHz, power 700W for 5 minutes, after standing for 10 minutes, continue microwave trea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com