One-step preparation method of metal oxide at chlorine doped graphene anode material for lithium ion battery

A technology for lithium ion batteries and negative electrode materials, applied in battery electrodes, active material electrodes, negative electrodes, etc., can solve the problems of poor consistency of negative electrode materials and cumbersome methods, and achieve the advantages of simple methods, reduced preparation time, and good cycle stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

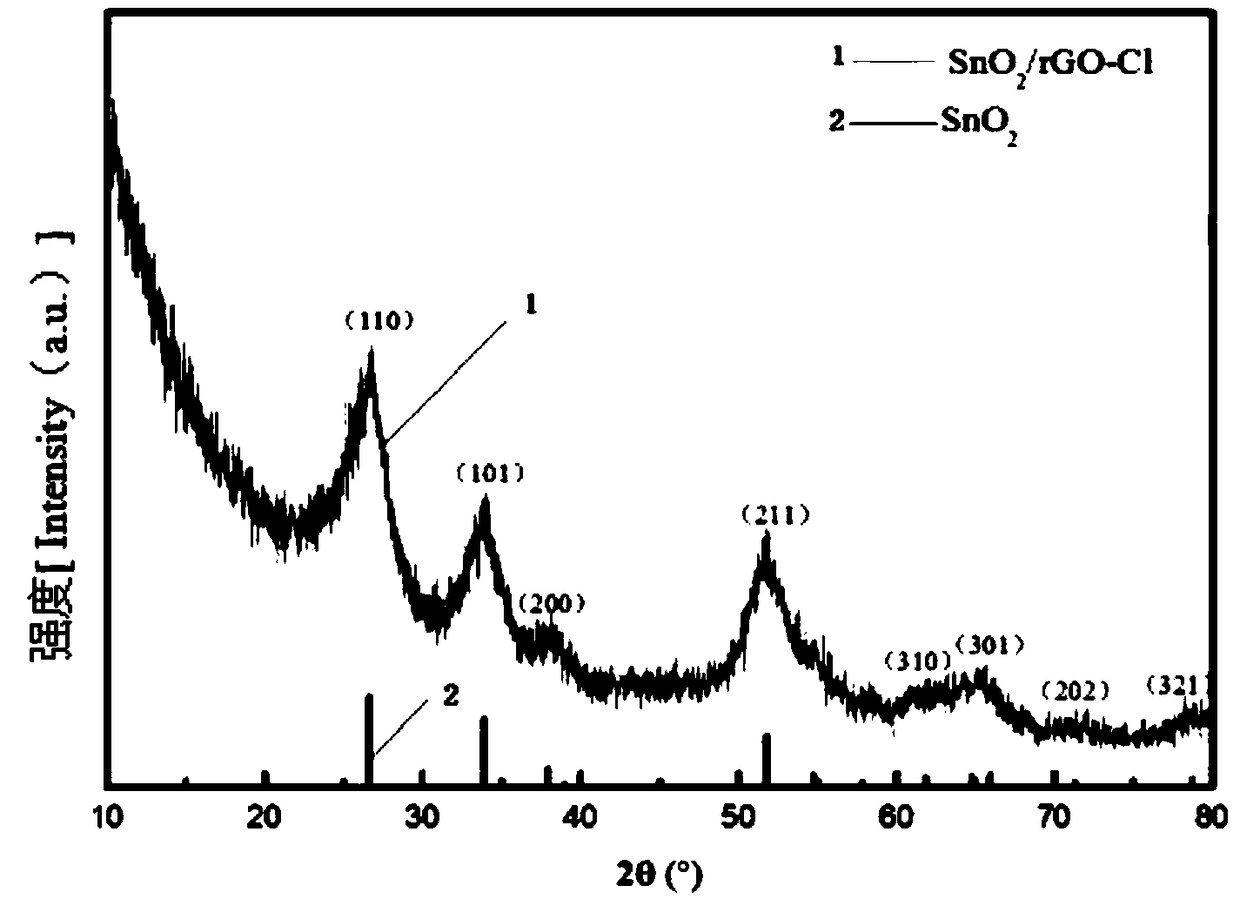

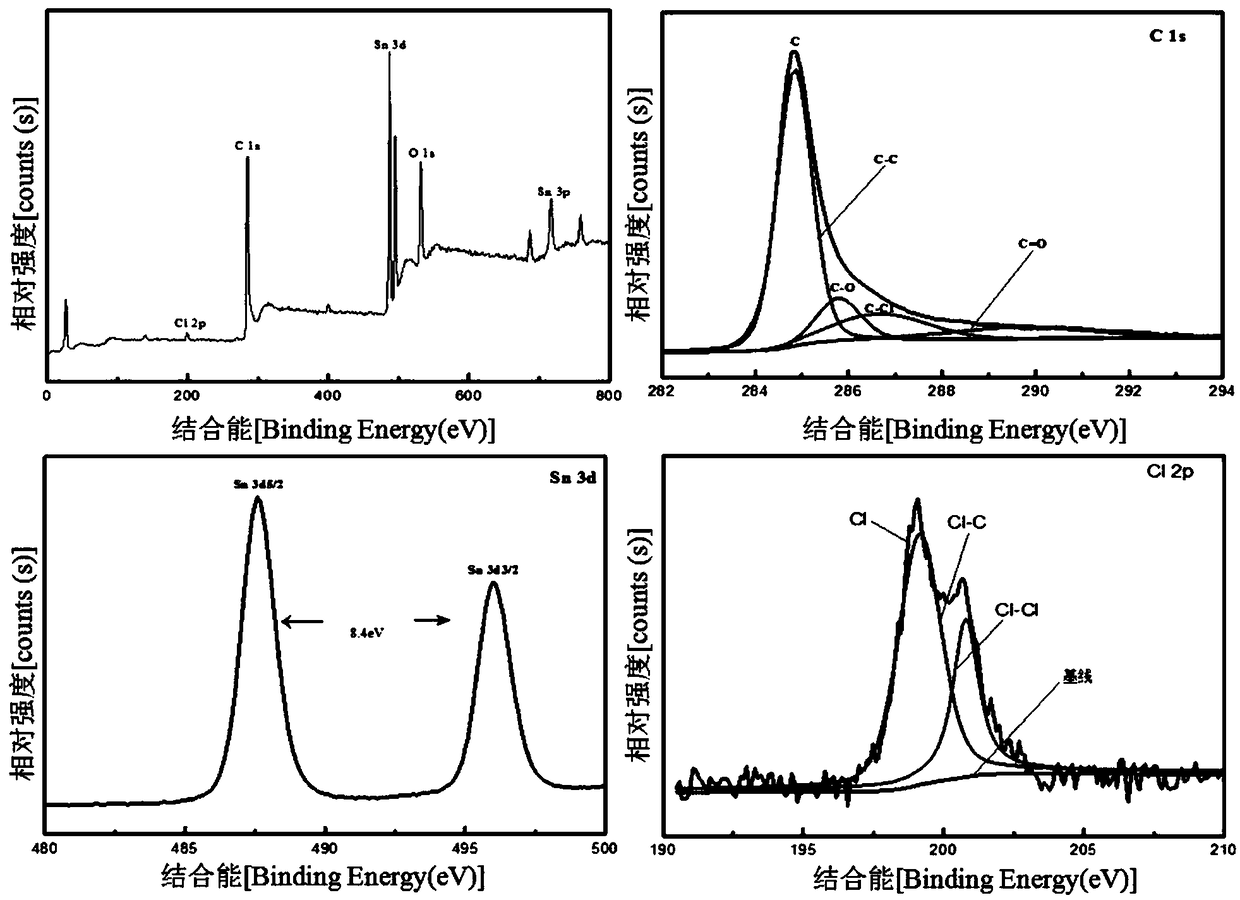

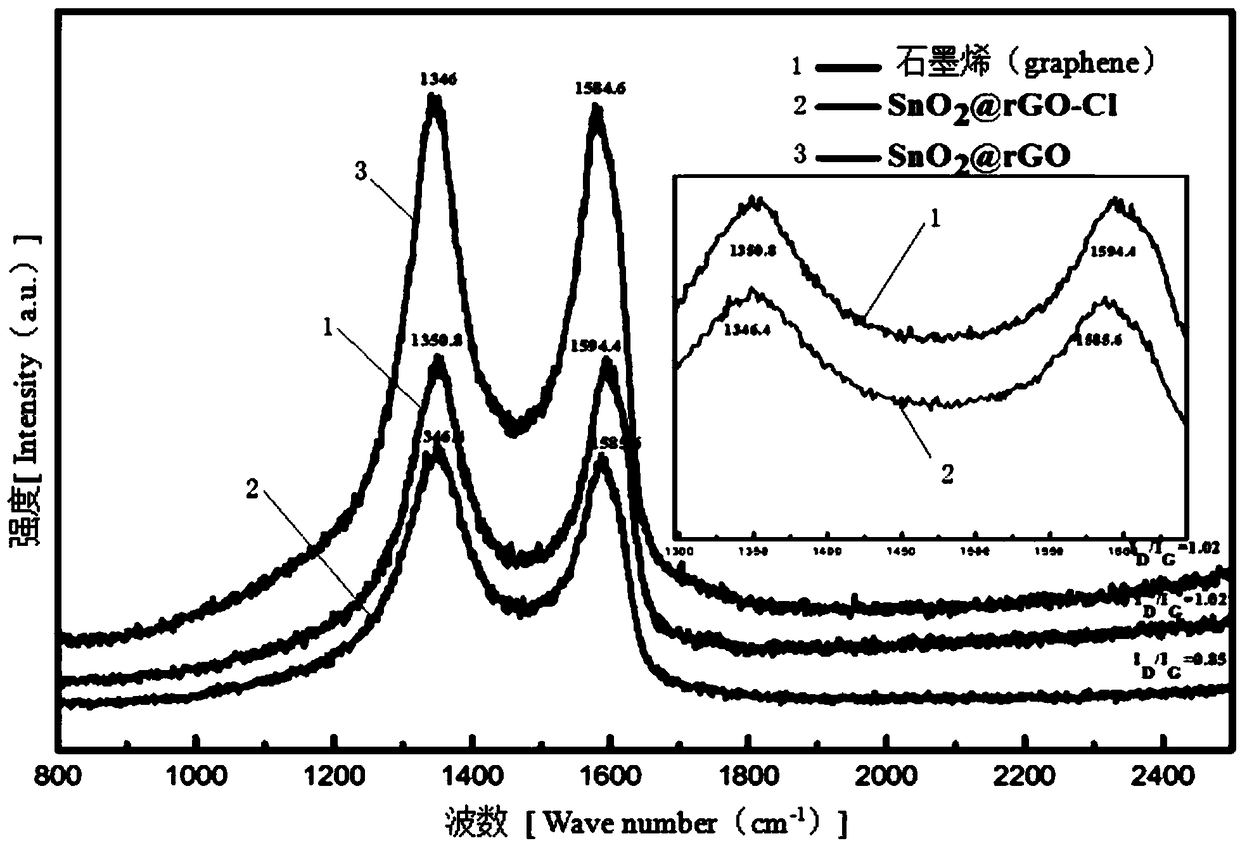

[0045] Embodiment 1: the method for preparing metal oxide@chlorine-doped graphene lithium-ion battery negative electrode material in one step in the present embodiment is characterized in that the preparation method is carried out according to the following steps:

[0046] Step 1. Add 0.4g of graphene oxide (GO) into 20mL of N-methylpyrrolidone (NMP), stir at 500rpm for 24h, and ultrasonicate for 1h at an ultrasonic frequency of 20KHz to obtain a uniformly dispersed GO slurry;

[0047] Step two, 0.375g SnCl 2 Dissolved in 5mL N-methylpyrrolidone (NMP), slowly added to the GO slurry, stirred at 500rpm at room temperature for 12h, to obtain SnCl 2 @GO gel;

[0048] Step three, the SnCl 2 @GO gel is evenly coated on the copper foil (the film thickness is about 200um), blown and dried at 70°C for 1 hour, then cut into pole pieces with a diameter of ф12mm, and then placed in a tube furnace, under the protection of argon at 390 ℃ calcination for 2h to obtain lithium-ion battery a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com