Micro-nano-TiC particle reinforced steel and preparation method thereof

A particle-strengthening and nano-technology, applied in the field of high-performance structural steel preparation, can solve the problem of uneven dispersion, achieve the effects of stable interface bonding, promoting dispersion and improving wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

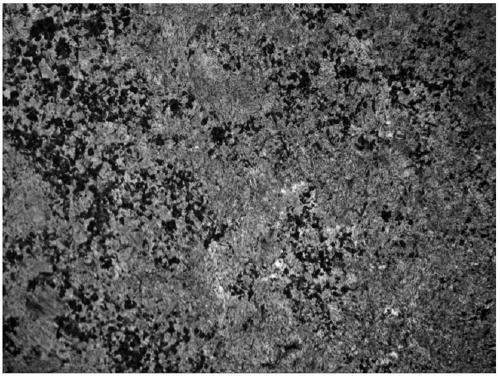

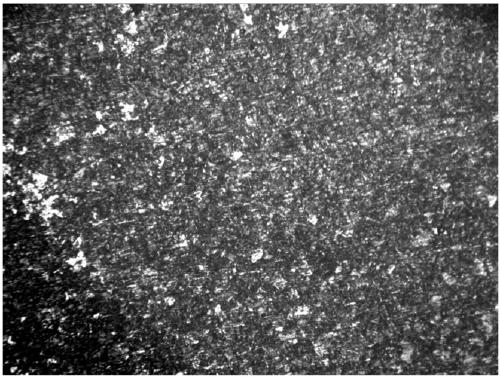

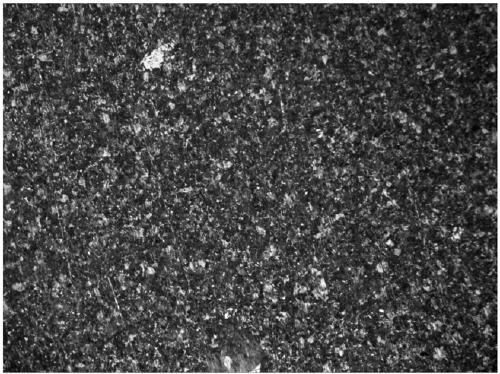

Image

Examples

preparation example Construction

[0051] The present invention also provides a method for preparing micro-nano TiC particle reinforced steel, which includes the following steps:

[0052] Step 1. After mixing carbon nanotubes, carbon black, iron powder, and titanium powder into a mixed powder, prepare a cylindrical Fe-Ti-C compact;

[0053] Step two: preparing the pre-dispersed master alloy of nanometer TiC particles by in-situ sintering the Fe-Ti-C compact;

[0054] Step 3: Disperse the nano-TiC particle pre-dispersed master alloy in the molten steel through a non-oxidation steelmaking process, and prepare a small amount of in-situ nano-TiC particles to strengthen and toughen ordinary carbon steel through a casting process;

[0055] Step 4: The micro-in-situ nano-TiC particles are strengthened and toughened ordinary carbon steel in sequence through homogenization treatment process, grain ultra-refining treatment process, and tempering process to obtain micro-nano-TiC particle reinforced steel.

[0056] The purity of the...

Embodiment 1

[0137] This embodiment provides a method for improving the strength and toughness of steel with trace nano-ceramic particles, which includes the following steps:

[0138] Step 1. The preparation of compacts containing cylindrical Fe-Ti-C is as follows:

[0139] Pretreatment of reactant powder by ball milling and preparation of reaction compacts:

[0140] a. Put 2 grams of carbon nanotubes (with a purity of 90wt.%) into a ball milling tank, and put the prepared reactant powder and zirconia grinding balls into a mixing tank. The diameter of the tank is 5mm, 7mm, 11mm, 15mm, 20mm, 22mm ZrO 2 Balls, 4 of each, ZrO 2 The ball mass is 320g, the ball-to-material ratio is set to 115:1, and the carbon nanotubes are activated by high-speed ball milling at a speed of 200r / min for 2h with a planetary ball mill.

[0141] b. Add 2 grams of carbon black (amorphous carbon) to the ball mill tank after 2 grams of carbon nanotube ball milling treatment, 80g of 300 mesh pure iron powder with a purity of ...

Embodiment 2

[0160] The method for improving the strength and toughness of steel with trace nano-ceramic particles of this embodiment is characterized in that it comprises the following steps:

[0161] Step 1. The preparation of cylindrical Fe-Ti-C compact is as follows:

[0162] Pretreatment of reactant powder by ball milling and preparation of reaction compacts:

[0163] a. Put 7 grams of carbon nanotubes (purity of 90wt.%) into a ball milling tank, and put the prepared reactant powder and zirconia grinding balls into a mixing tank. The diameter of the tank is 5mm, 7mm, 11mm, 15mm, 20mm, 22mm ZrO 2 Balls, 10 of each, ZrO 2 The ball mass is 600g, the ball-to-material ratio is set to 135:1, and the carbon nanotubes are activated by high-speed ball milling at a speed of 300r / min for 3h with a planetary ball mill.

[0164] b. Add 65 g of 1000 mesh pure iron powder with a purity of 99.0 wt.% to the 7 g of carbon nanotube ball milling tank; 28 g of 800 mesh titanium powder with a purity of 99.0 wt.%, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact toughness | aaaaa | aaaaa |

| Impact toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com