Preparation method of high performance polymer-based composite dielectric material

A high-performance polymer and dielectric material technology, applied in the field of dielectric material preparation, can solve the problems of low dielectric constant, and achieve the effects of good stability, good high temperature resistance, high dielectric constant and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

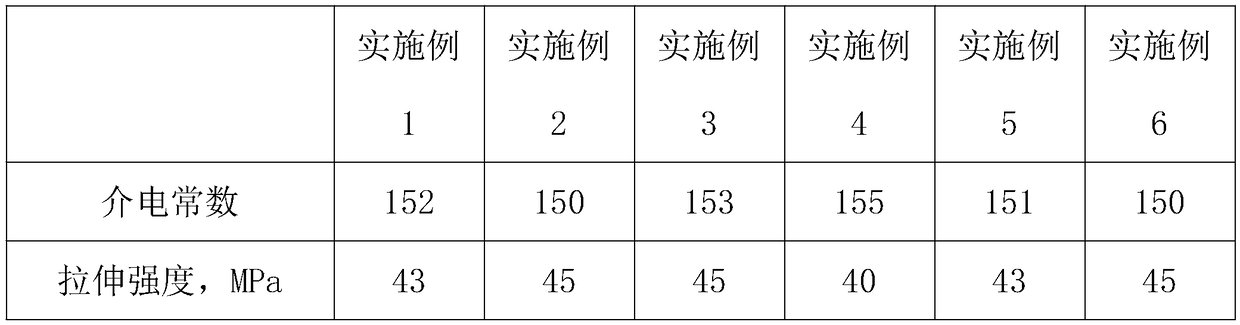

Examples

Embodiment 1

[0024] A method for preparing a high-performance polymer-based composite dielectric material, comprising the following steps:

[0025] (1) Mix nano-barium titanate, silane coupling agent and absolute ethanol, ultrasonically treat for 1 hour at a power of 500W, filter after the treatment, and dry the solid to obtain modified nano-barium titanate; wherein, the nano-barium titanate The dosage ratio of barium titanate, silane coupling agent and absolute ethanol is 1g: 0.01mL: 30mL;

[0026] (2) Dissolve the modified nano-barium titanate in an organic solvent, then add maleic anhydride, stir and mix evenly, react at 40°C for 2 hours, filter after the reaction, and dry the precipitate to obtain maleic anhydride Branch modified nano barium titanate; Wherein, the mass ratio of described modified nano barium titanate, maleic anhydride is 1:0.3;

[0027] (3) Mix the maleic anhydride graft-modified nano-barium titanate prepared above with deionized water, then add an emulsifier, stir an...

Embodiment 2

[0030] A method for preparing a high-performance polymer-based composite dielectric material, comprising the following steps:

[0031] (1) Mix nano-barium titanate, silane coupling agent and absolute ethanol, ultrasonically treat for 3 hours at a power of 1000W, filter after the treatment, and dry the solid to obtain modified nano-barium titanate; wherein, the nano-barium titanate The dosage ratio of barium titanate, silane coupling agent and absolute ethanol is 1g: 0.05mL: 30mL;

[0032] (2) Dissolve the modified nano-barium titanate in an organic solvent, then add maleic anhydride, stir and mix evenly, react at 60°C for 5 hours, filter after the reaction, and dry the precipitate to obtain maleic anhydride Branch modified nano barium titanate; Wherein, the mass ratio of described modified nano barium titanate, maleic anhydride is 1:0.5;

[0033] (3) Mix the above-mentioned maleic anhydride graft-modified nano-barium titanate and deionized water, then add an emulsifier, stir ...

Embodiment 3

[0036] A method for preparing a high-performance polymer-based composite dielectric material, comprising the following steps:

[0037] (1) Mix nano-barium titanate, silane coupling agent and dehydrated alcohol, ultrasonically treat for 1.5h under 600W power, filter after the treatment, and dry the solid to obtain modified nano-barium titanate; wherein, the The dosage ratio of nano barium titanate, silane coupling agent and absolute ethanol is 1g: 0.02mL: 30mL;

[0038] (2) Dissolve the modified nano-barium titanate in an organic solvent, then add maleic anhydride, stir and mix evenly, react at 45°C for 3 hours, filter after the reaction, and dry the precipitate to obtain maleic anhydride Branch modified nano barium titanate; Wherein, the mass ratio of described modified nano barium titanate, maleic anhydride is 1:0.35;

[0039] (3) Mix the above-mentioned maleic anhydride graft-modified nano barium titanate and deionized water, then add an emulsifier, stir and mix evenly, add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com