Synthesis method of O-nitrophenylacetic acid

A synthesis method and technology of o-nitrobenzene are applied in chemical instruments and methods, preparation of organic compounds, metal/metal oxide/metal hydroxide catalysts, etc., and can solve the problems of difficulty in obtaining, high cost, poor safety, etc. , to achieve the effect of strengthening the separation effect, shortening the reaction time and improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

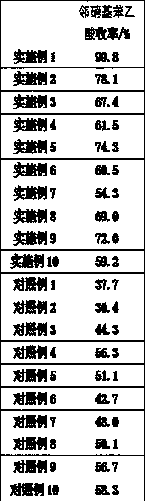

Examples

Embodiment 1

[0018] A kind of synthetic method of intermediate o-nitrophenylacetic acid is characterized in that the method comprises the following steps:

[0019] Step 1. Add 100ml of absolute ethanol into a 500ml four-necked flask equipped with a thermometer, and gradually add 0.1g of catalyst Pt-MgO-CNTs and 8g of sodium metal while stirring;

[0020] Step 2. After the reaction is completed, when the temperature drops to room temperature, add 35ml o-nitrotoluene and 56ml diethyl oxalate, heat to 45°C for 3 hours, then add water and heat up to 60°C for hydrolysis reaction;

[0021] Step 3. After reacting for 1 hour, lower the temperature to 35° C. and carry out vacuum distillation until the distilled components are cloudy liquids. will reverse

[0022] Cool the solution to 10°C and adjust the pH to 7 with sodium hydroxide solution;

[0023] Step 4, then dropwise add hydrogen peroxide solution with a concentration of 0.3M, control its dropping speed, keep the temperature below 20°C, and...

Embodiment 2

[0031] Step 2. After the reaction is completed, when the temperature drops to room temperature, add 30ml of o-nitrotoluene and 56ml of diethyl oxalate, heat to 45°C for 3 hours, then add water and heat up to 60°C for hydrolysis reaction; the rest of the steps are the same as in Example 1 .

Embodiment 3

[0033] Step 2. After the reaction is completed, when the temperature drops to room temperature, add 25ml o-nitrotoluene and 56ml diethyl oxalate, heat to 45°C for 3 hours, then add water and heat up to 60°C for hydrolysis reaction; the rest of the steps are the same as in Example 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com