A Method of Improving the Strength and Corrosion Resistance of Cast ZK21 Magnesium Alloy

A casting magnesium alloy, ZK21 technology, applied in the field of casting ZK21 magnesium alloy process treatment, can solve the problems of poor corrosion resistance degradation speed, corrosion performance deterioration, poor corrosion resistance and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

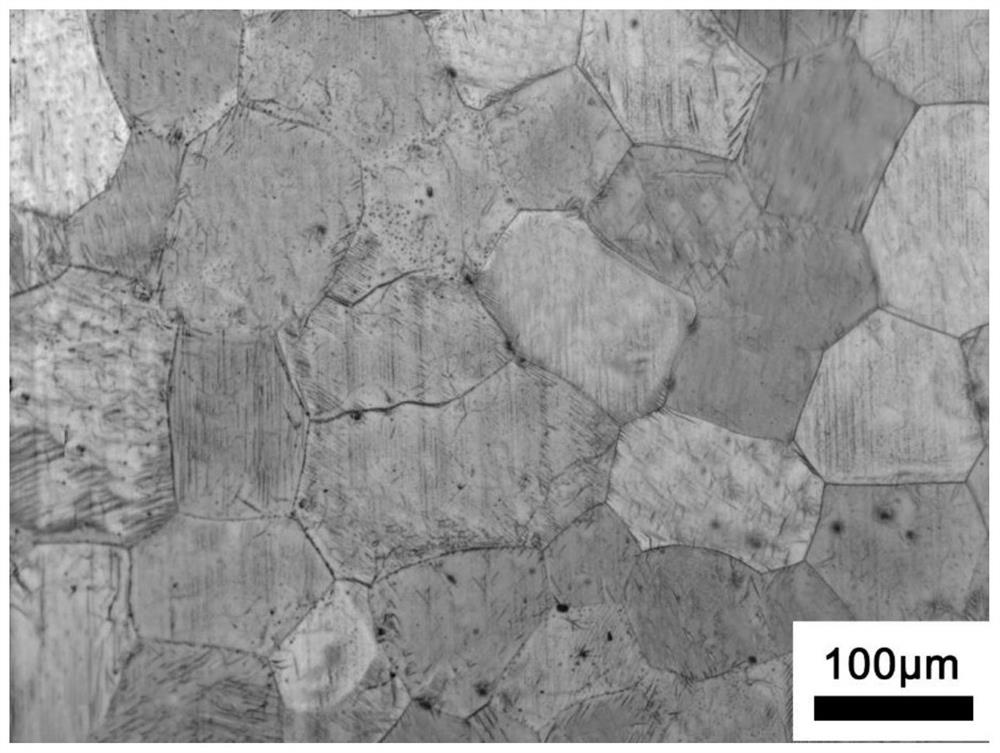

[0021] The components and mass percentages of the ZK21 cast magnesium alloy used are: Zn: 1.87%, Zr: 0.54%, and the rest are Mg and unavoidable impurities. The magnesium alloy above was subjected to solid solution treatment at a temperature of 360°C and a holding time of 12 hours. In order to prevent oxidation, pyrite powder (FeS 2 ) as protection; water cooled to room temperature. Then, the solution-treated magnesium alloy is extruded into rods through extrusion at an extrusion temperature of 350° C. and an extrusion speed of 3 mm / s.

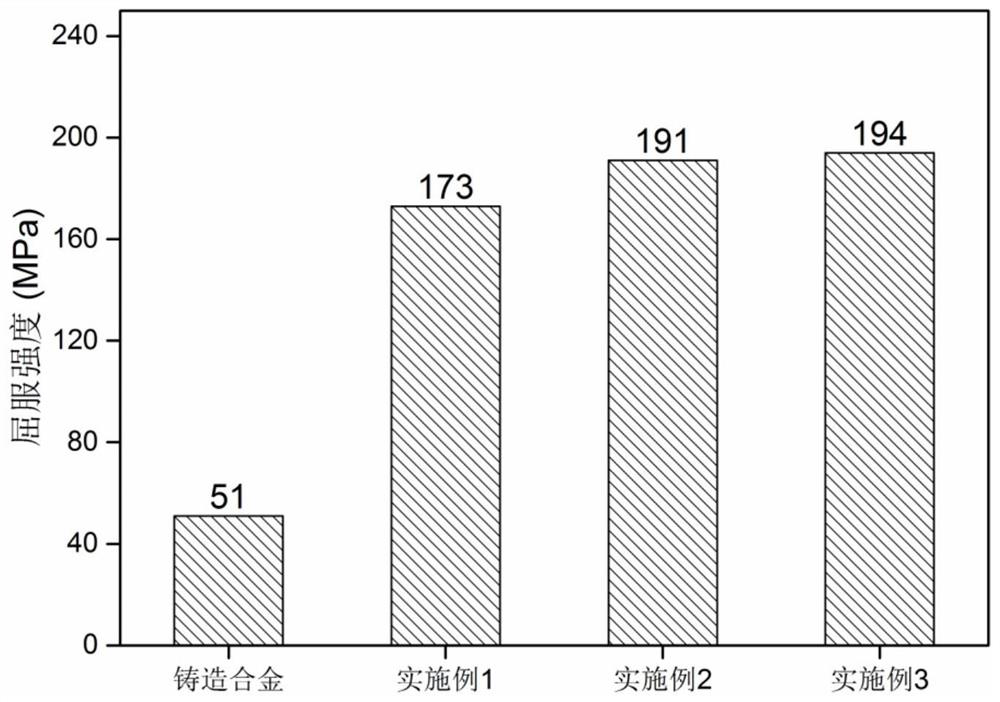

[0022] The properties of the alloy obtained in this embodiment are as follows: the yield strength is 173 MPa, and the average corrosion rate after soaking in Hank's solution for 240 hours is 0.55 mm / year.

Embodiment 2

[0024] The components and mass percentages of the ZK21 cast magnesium alloy used are: Zn: 1.87%, Zr: 0.54%, and the rest are Mg and unavoidable impurities. The magnesium alloy above was subjected to solid solution treatment at a temperature of 400°C and a holding time of 12 hours. In order to prevent oxidation, pyrite powder (FeS 2 ) as protection; water cooled to room temperature. Then, the solution-treated magnesium alloy is extruded into rods through extrusion at an extrusion temperature of 350° C. and an extrusion speed of 3 mm / s.

[0025] The properties of the alloy obtained in this embodiment are as follows: the yield strength is 191MPa, and the average corrosion rate after soaking in Hank's solution for 240 hours is 0.48mm / year.

Embodiment 3

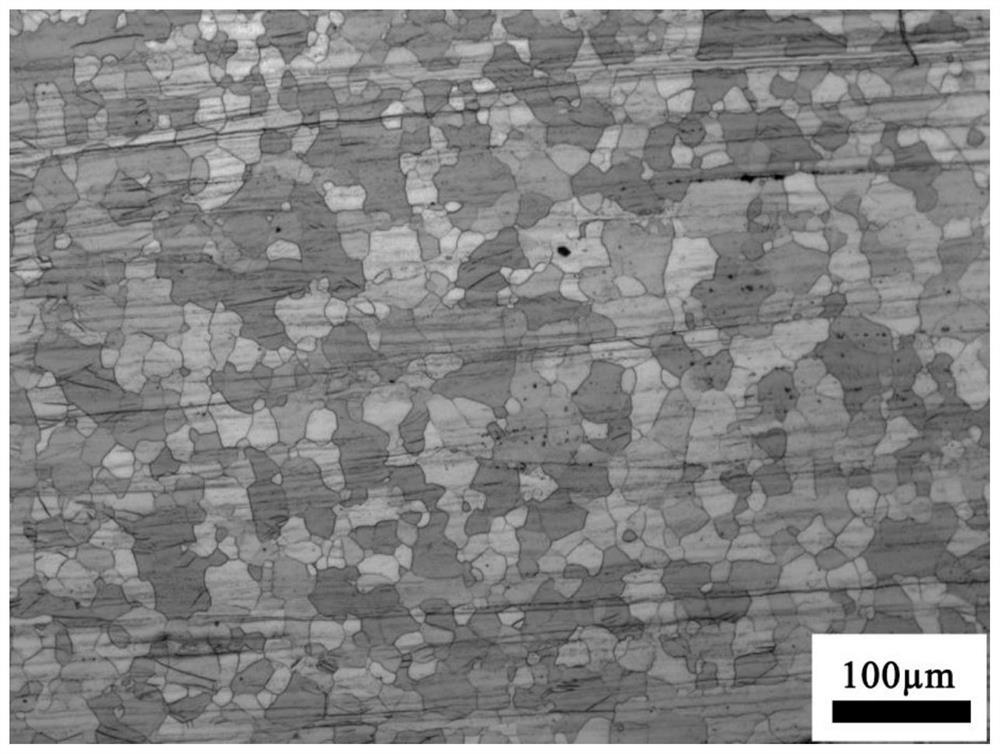

[0027] The components and mass percentages of the ZK21 cast magnesium alloy used are: Zn: 1.87%, Zr: 0.54%, and the rest are Mg and unavoidable impurities. The magnesium alloy above was subjected to solid solution treatment at a temperature of 400°C and a holding time of 24 hours. In order to prevent oxidation, pyrite powder (FeS 2 ) as protection; water cooled to room temperature. Then, the solution-treated magnesium alloy is extruded into rods through extrusion at an extrusion temperature of 350° C. and an extrusion speed of 3 mm / s.

[0028] The properties of the alloy obtained in this embodiment are as follows: the yield strength is 194MPa; the average corrosion rate after soaking in Hank's solution for 240 hours is 0.32mm / year.

[0029] Comparative analysis of the three examples shows that Example 3 has the best overall performance, and has both excellent strength and corrosion resistance. Its properties are as follows: the yield strength is 194MPa, and the average corro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com