Chromium-zirconium-copper alloy and preparation method thereof

A chromium zirconium copper and alloy technology, applied in the field of alloys, can solve the problems of large particle spacing of product structure, unsuitable for billet processing, high alloy porosity and oxygen content, and achieve uniform alloy structure, improve uniformity, and good structure uniformity. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

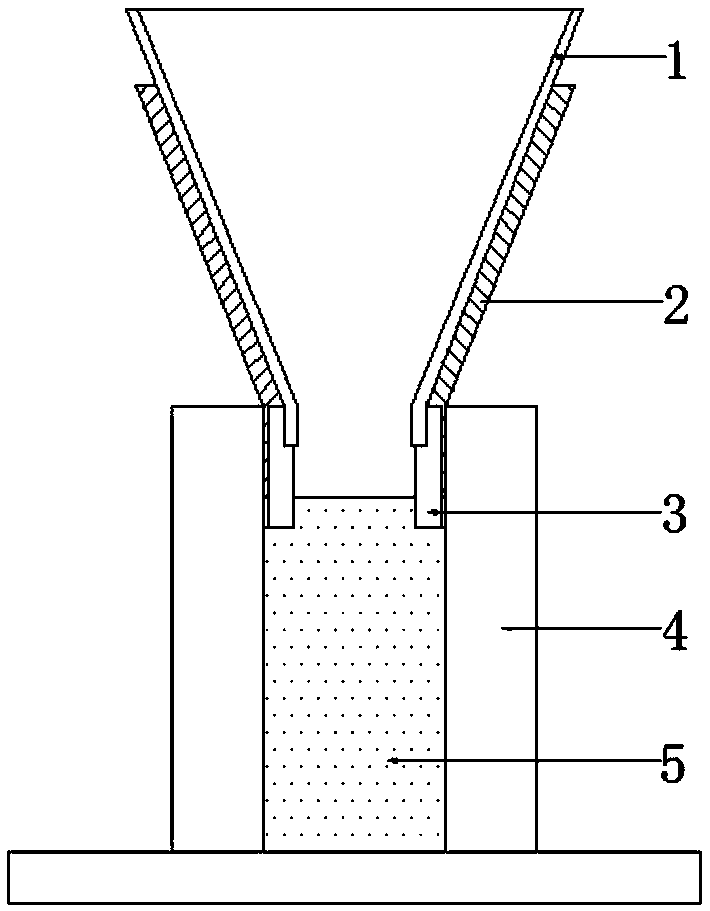

Image

Examples

Embodiment 1

[0087] According to the preset composition: 10wt% chromium, 0.3wt% zirconium, 0.5wt% magnesium and mixed rare earths (rich in lanthanum, cerium, praseodymium, neodymium rare earth elements), the balance is copper, chromium zirconium copper alloy Weighing:

[0088] The raw material of chromium element is chromium powder with a particle size of 1mm, and the burning loss is calculated as 3%; the raw material of zirconium element is zirconium sponge with a particle size of 1mm, and the burning loss is calculated as 14%; the raw material of magnesium and mixed rare earths is pure Magnesium and cerium-rich mixed rare earth, the raw materials of copper element are copper foil, oxygen-free copper rod, copper plate and copper pellets, the mass of copper foil is 38g (the mass content is less than 0.5% of the total mass of the raw material of copper element), oxygen-free The copper rod is 75% of the total copper raw material mass, the copper particle is 22.7% of the total copper raw mate...

Embodiment 2

[0111] According to the preset composition: 8wt% chromium, 0.01wt% zirconium, 0.01wt% magnesium and mixed rare earth (rich in lanthanum, cerium, praseodymium, neodymium rare earth elements), the balance is copper, chromium-zirconium-copper alloy Weighing:

[0112]The raw material of chromium element is chromium powder with a particle size of 0.9mm, and the burning loss is calculated as 2%; the raw material of zirconium element is sponge zirconium with a particle size of 0.9mm, and the burning loss is calculated as 11%; the raw material of magnesium and mixed rare earths is 0.9mm mm of pure magnesium and cerium-rich mixed rare earth, the raw materials of copper element are copper foil, oxygen-free copper rod, copper plate and copper pellets, the mass of copper foil is 35g (the mass content is less than 0.5% of the total mass of the raw material of copper element), The oxygen-free copper rod is 71.2% of the mass of the total copper raw material, and the copper particle is 25% of...

Embodiment 3

[0135] According to the preset composition: 15wt% chromium, 0.5wt% zirconium, 1wt% magnesium and mixed rare earths (rich in lanthanum, cerium, praseodymium, and neodymium rare earth elements), the balance is copper, and the chromium-zirconium-copper alloy is weighed material:

[0136] The raw material of chromium element is chromium powder with a particle size of 2mm, and the burning loss is calculated as 5%; the raw material of zirconium element is sponge zirconium with a particle size of 2mm, and the burning loss is calculated as 17%; the raw material of magnesium and mixed rare earths is pure Magnesium and cerium-rich mixed rare earth, the raw materials of copper element are copper foil, oxygen-free copper rod, copper plate and copper particles, the mass of copper foil is 35g (the mass content is less than 0.5% of the total mass of copper element raw materials), oxygen-free copper The rod is 70% of the mass of the total copper raw material, and the copper particles are 25.8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com