Preparation method of bamboo-based polycaprolactone composite sheet material modified by nano-silica and nano-titanium dioxide

A technology of nano-silica and nano-titanium dioxide, which is applied in the direction of coating, etc., can solve the problems of easy aging, insufficient antibacterial and anti-mildew performance, etc., and achieve strong anti-bacterial and anti-mildew performance, good anti-thermal oxygen aging performance, anti-thermal oxygen aging The effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

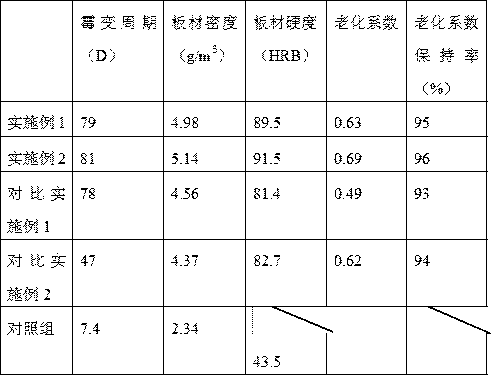

Examples

Embodiment 1

[0027] A preparation method for modifying bamboo base-polycaprolactone composite sheet with nano silicon dioxide-nano titanium dioxide, comprising the steps of:

[0028] (1) Modification method of silica:

[0029] Dry 4 parts of nano-silica at 200-205 °C for 2 hours, mix and disperse with 0.02 parts of silane coupling agent and 140 parts of toluene solution, heat and reflux in a reaction kettle at 105-115 °C for 9 hours, cool, and rotate to evaporate centrifuged, washed 3 times with absolute ethanol, and dried to obtain modified nano-silica;

[0030] (2) Pressing process of bamboo-polycaprolactone composite sheet:

[0031] After mixing 95 parts of polycaprolactone with modified bamboo powder, hydrophobized modified bamboo fiber, the material obtained in (1) and the silica immobilized antioxidant in a twin-roller masticator at 80-85°C for 11 minutes , pressed on a hot press for 10 minutes;

[0032] (3) Antibacterial and mildew-proof modification of bamboo nano-titanium dioxi...

Embodiment 2

[0044] A preparation method for modifying bamboo base-polycaprolactone composite sheet with nano silicon dioxide-nano titanium dioxide, comprising the steps of:

[0045] (1) Modification method of silica:

[0046] Dry 4 parts of nano-silica at 200-205 °C for 2 hours, mix and disperse with 0.02 parts of silane coupling agent and 140 parts of toluene solution, heat and reflux in a reaction kettle at 105-115 °C for 9 hours, cool, and rotate to evaporate centrifuged, washed 5 times with absolute ethanol, and dried to obtain modified nano-silica;

[0047] (2) Pressing process of bamboo-polycaprolactone composite sheet:

[0048] After mixing 105 parts of polycaprolactone with modified bamboo powder, hydrophobized modified bamboo fiber, the material obtained in (1) and the silica immobilized antioxidant in a double-roller masticator at 80-85°C for 11 minutes , pressed on a hot press for 10 minutes;

[0049] (3) Antibacterial and mildew-proof modification of bamboo nano-titanium di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com