Black copper sludge dearsenification device and method

A black copper slime and arsenic removal technology, applied in the chemical industry, can solve the problems of inability to effectively separate arsenic and other valuable metals, low metal recovery rate, low leaching rate, etc. Arsenic leaching rate, enhanced ion diffusion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

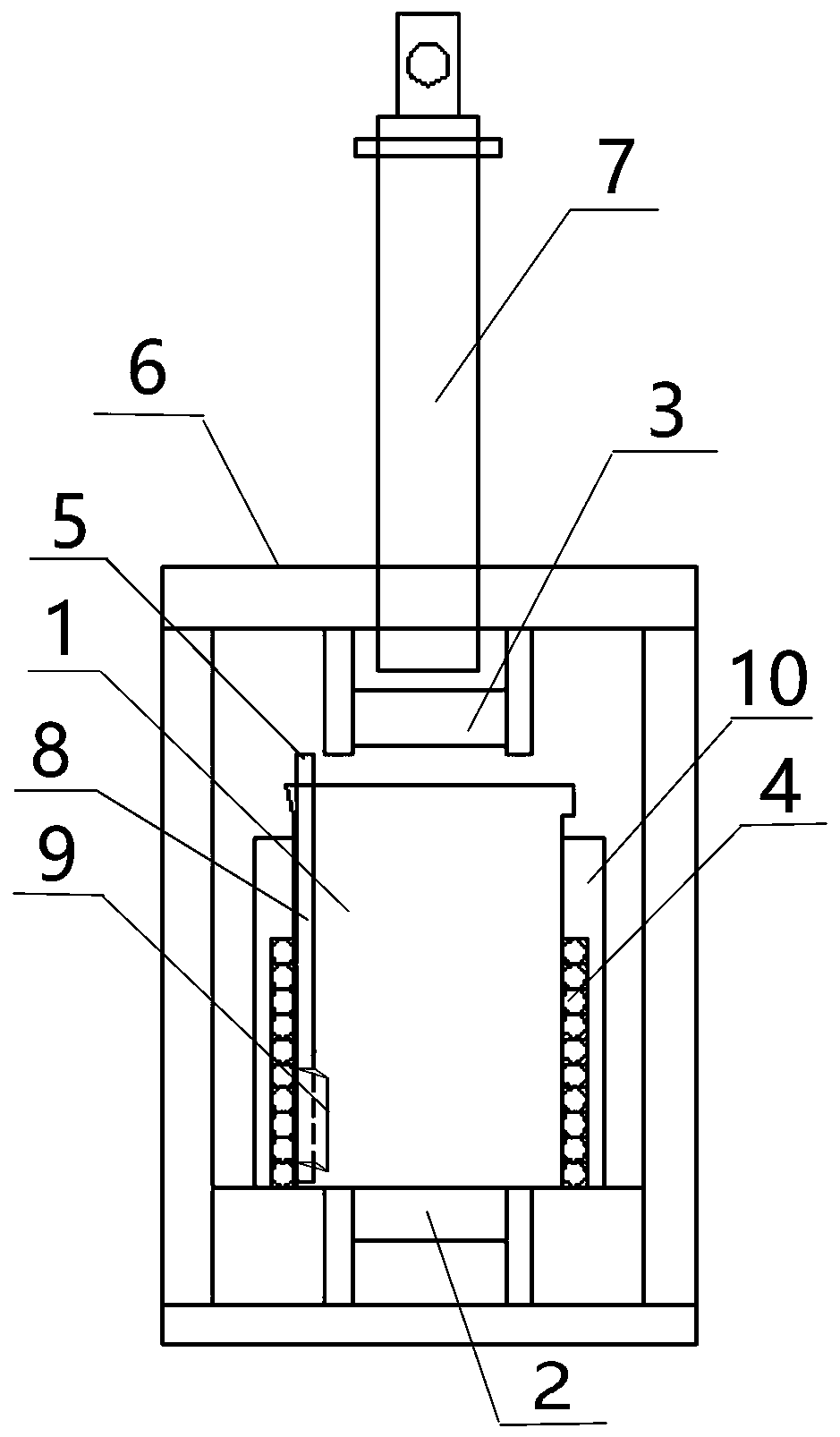

[0024] A method for removing arsenic from black copper mud, comprising the following steps: adding 33.78g of NaOH solid to reaction tank 1 for the first time, then adding 500ml of water to reaction tank 1 to completely dissolve NaOH solid, starting heating device 4 to heat NaOH solution to 80 At ~85°C, add 50g of black copper mud into the reaction tank 1, and at the same time, the air injection stirring device 5 injects air into the reaction tank with an air injection pressure of 3~5 MPa and stirs. Add 33.78g NaOH solid for the second time within 1, continue gas injection and stirring reaction under the magnetic field strength 1T for 2h, obtain leaching liquid and leaching slag, after chemical analysis of leaching liquid and leaching slag, it is detected that the leaching rate of arsenic reaches 92%, copper The enrichment rate reaches 62%, and the copper in the leaching slag is elemental copper powder.

Embodiment 2

[0026] A method for removing arsenic from black copper slime, comprising the following steps: adding 33.78g of NaOH solid to reaction tank 1 for the first time, then adding 500ml of water to reaction tank 1 to completely dissolve NaOH solid, starting heating device 4 to heat NaOH solution to 80 At ~85°C, add 50g of black copper mud into the reaction tank 1, and at the same time, the air injection stirring device 5 injects air into the reaction tank with an air injection pressure of 3~5 MPa and stirs. After reacting for 2 hours under a magnetic field strength of 2T, the Add 33.78g NaOH solid for the second time within 1, continue to inject gas and stir the reaction for 2h under the magnetic field strength 2T, and obtain the leaching solution and leaching residue. After chemical analysis of the leaching solution and leaching residue, it is detected that the leaching rate of arsenic reaches 95%. The enrichment rate reaches 71.6%, and the copper in the leaching slag is elemental co...

Embodiment 3

[0028] A method for removing arsenic from black copper slime, comprising the following steps: adding 33.78g of NaOH solid to reaction tank 1 for the first time, then adding 500ml of water to reaction tank 1 to completely dissolve NaOH solid, starting heating device 4 to heat NaOH solution to 80 At ~85°C, add 50g of black copper mud into the reaction tank 1, and at the same time, the air injection stirring device 5 injects air into the reaction tank with an air injection pressure of 3~5 MPa and stirs. Add 33.78g NaOH solid for the second time within 1, and continue to inject gas and stir the reaction for 2h under the magnetic field strength 3T to obtain the leaching solution and leaching residue. After chemical analysis of the leaching solution and leaching residue, it is detected that the leaching rate of arsenic reaches 96.4%. The enrichment rate reaches 80%, and the copper in the leaching slag is elemental copper powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com