Preparation method of copper nanorod reinforced asphalt planting roof root resistance material

A copper nanorod and root blocking technology is applied in the field of preparation of copper nanorod reinforced asphalt planting roof root blocking materials, which can solve problems such as flue gas, achieve the effects of environmental friendliness, improve waterproof root blocking performance, and reduce construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

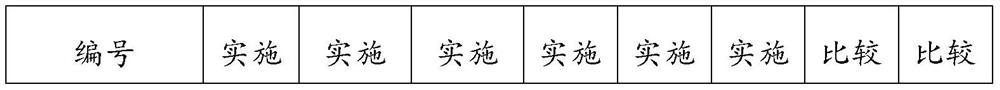

Examples

Embodiment 1

[0026] Step 1: Under mechanical stirring, dissolve 40 parts of copper chloride in a mixed solution of 50 parts of ethanol and 50 parts of deionized water, add 2 parts of ammonia water, add 10 parts of sodium borohydride, and then add 3 parts of 1% Gelatin hydrolyzate and 2 parts of polyvinylpyrrolidone were dispersed and dissolved for 0.5 hours. The mixed solution is heated to a temperature of 70-80 degrees Celsius, reacted for 2 hours, centrifuged, and washed with deionized water and ethanol to obtain copper nanorods.

[0027] Step 2: Take 10 parts of the prepared copper nanorods, add 30 parts into 5% low molecular weight polystyrene chloroform solution, heat the temperature to 40 degrees Celsius, and keep mechanical stirring for 1 hour, and obtain polystyrene modified copper nanorods .

[0028] Step 3: Add 20 parts of diesel oil to 100 parts of base petroleum asphalt, and change the base petroleum asphalt into a viscous flowable slurry by stirring and dissolving at a temper...

Embodiment 2

[0032] Step 1: Under mechanical stirring, dissolve 50 parts of copper chloride in a mixed solution of 50 parts of ethanol and 50 parts of deionized water, add 4 parts of ammonia water, and add 15 parts of sodium borohydride, then add 6 parts of 1% Gelatin hydrolyzate and 4 parts of polyvinylpyrrolidone were dispersed and dissolved for 1 hour. The mixed solution was heated to a temperature of 80 degrees Celsius, reacted for 4 hours, centrifuged, and washed with deionized water and ethanol to obtain copper nanorods.

[0033] Step 2: Take 20 parts of the prepared copper nanorods, add 40 parts into 5% low molecular weight polystyrene chloroform solution, heat the temperature to 60 degrees Celsius, and keep mechanical stirring for 2 hours, obtain polystyrene modified copper nanorods .

[0034] Step 3: Add 30 parts of diesel oil to 100 parts of base petroleum asphalt, and through stirring and dissolving at a temperature of 50° C., change the base petroleum asphalt into a viscous fl...

Embodiment 3

[0038] Step 1: Under mechanical stirring, dissolve 45 parts of copper chloride in a mixed solution of 50 parts of ethanol and 50 parts of deionized water, add 3 parts of ammonia water, and add 13 parts of sodium borohydride, then add 4 parts of 1% Gelatin hydrolyzate and 3 parts of polyvinylpyrrolidone were dispersed and dissolved for 1 hour. The mixed solution is heated to a temperature of 70-80 degrees Celsius, reacted for 3 hours, centrifuged, and washed with deionized water and ethanol to obtain copper nanorods.

[0039] Step 2: Take 15 parts of the prepared copper nanorods, add 35 parts into 5% low molecular weight polystyrene chloroform solution, heat the temperature to 50 degrees Celsius, and keep mechanical stirring for 1.5 hours, and obtain polystyrene modified copper nanorods .

[0040] Step 3: Add 25 parts of diesel oil to 100 parts of base petroleum asphalt, and through stirring and dissolving at a temperature of 45° C., change the base petroleum asphalt into a visc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com