Cable clamp

A cable fixture and fixture technology, which is applied to electrical components, pipe supports, pipes/pipe joints/pipe fittings, etc., can solve the problems of easy breakage of cable fixtures, high manufacturing costs, and inconvenience in manufacturing, and achieves simple structure, convenient manufacturing, and manufacturing. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

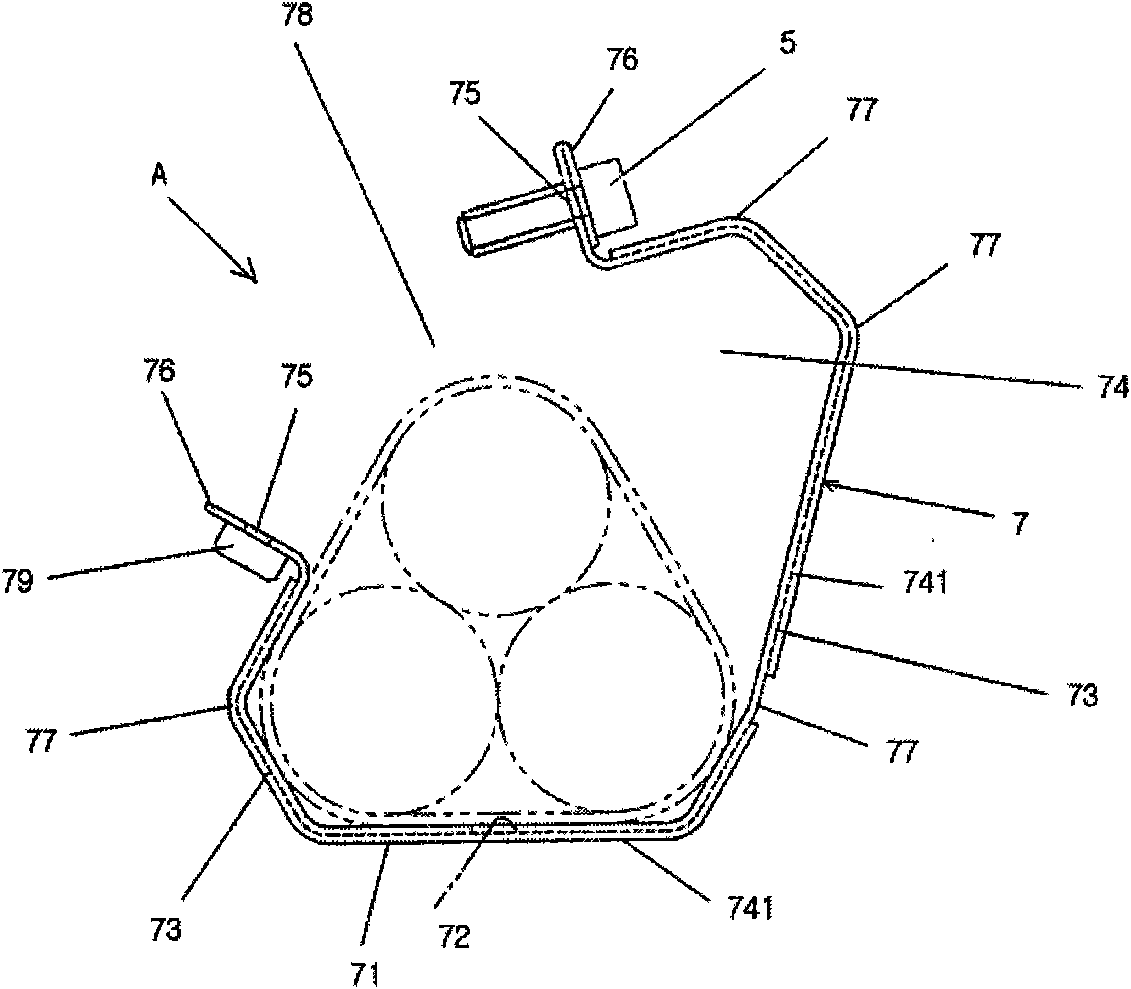

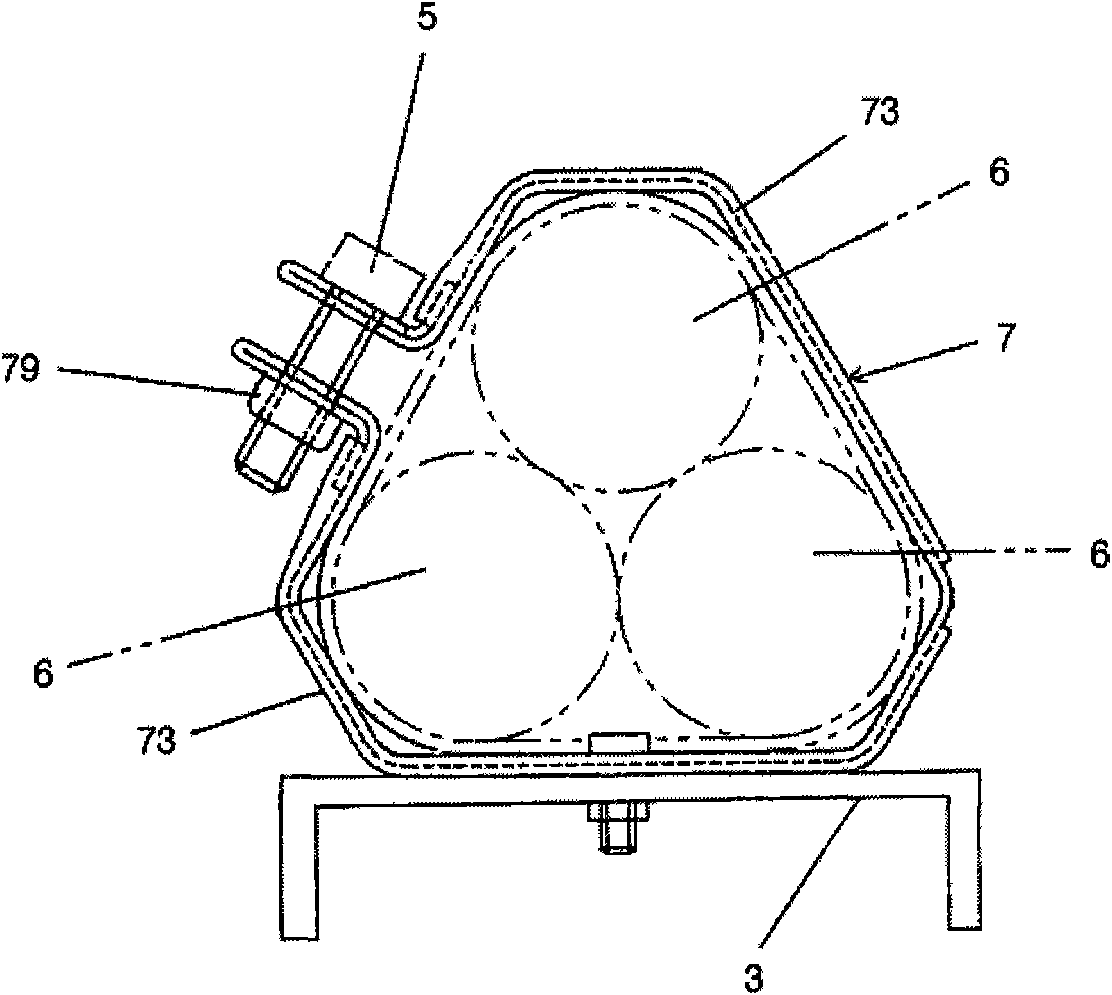

[0021] The cable clamp A in an embodiment of the present invention is as Figure 4 , Figure 5 As shown, it is composed of a hinge fixed fixture body 2 and a fixture cover 3 that can be opened and closed according to the rotation operation of the hinge shaft 1; the above fixture body 2 and fixture cover 3 can increase the strength, and are made of double-thickness edge protection with repeated twists and turns 21, 31 composition.

[0022] A clamping hole 22 is formed in the middle of the fixture body 2, and one end can be bent and extended upwards on the horizontal floor 24 with the hinge portion 23 on the fixed hinge shaft 1, and the above-mentioned horizontal floor 24 can be extended zigzagging upwards, and one end can form an outwardly inclined and zigzag joint 26; One end of the cover 3 has a hinge portion 33 that fixes the above-mentioned hinge shaft 1 and is extended upwards; in order to enable the cable to be received, it is connected to the curved curved portion 34 pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com