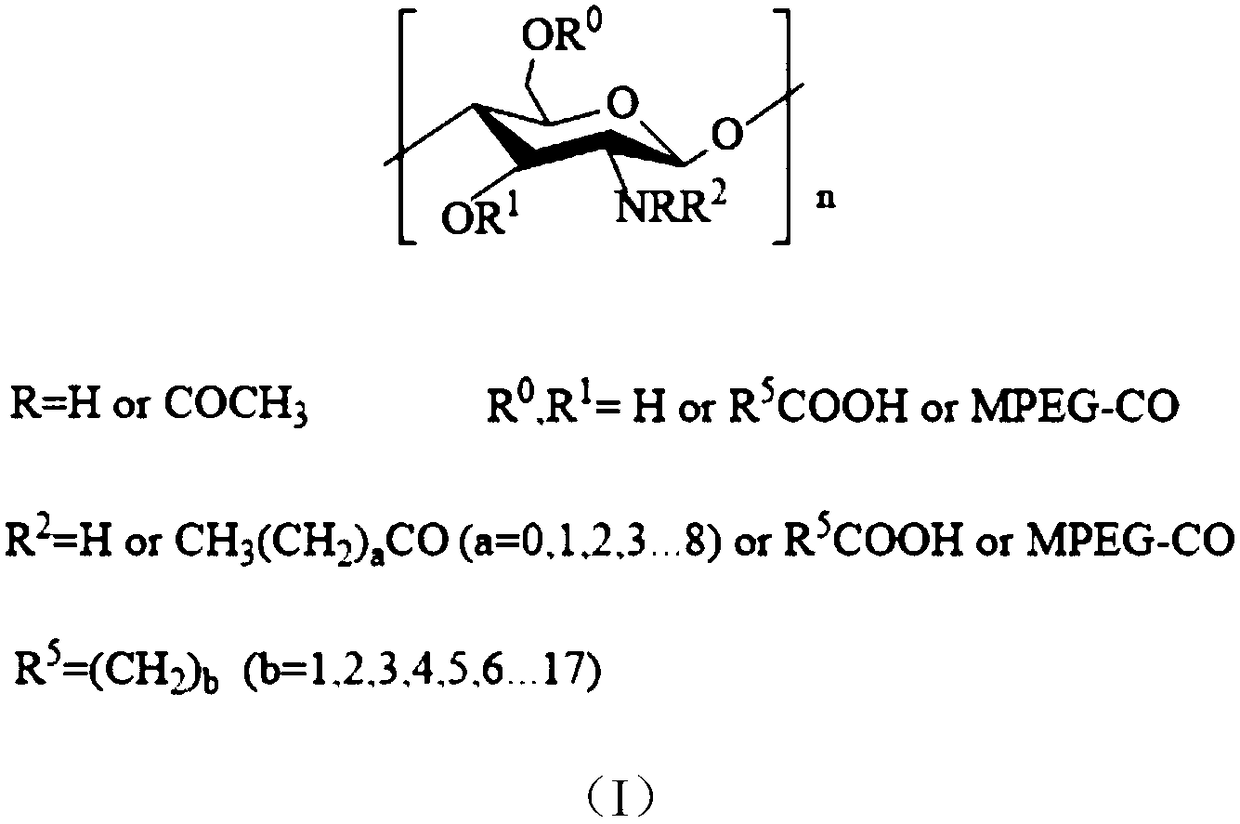

Modified chitosan type crude oil demulsifier and preparation method thereof

A technology of crude oil demulsifier and chitosan, which is applied in chemical dehydration/demulsification, petroleum industry, hydrocarbon oil treatment, etc., can solve the problems of poor environmental friendliness and secondary pollution of demulsifiers, and achieve strong competitive adsorption capacity , safe to use and wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

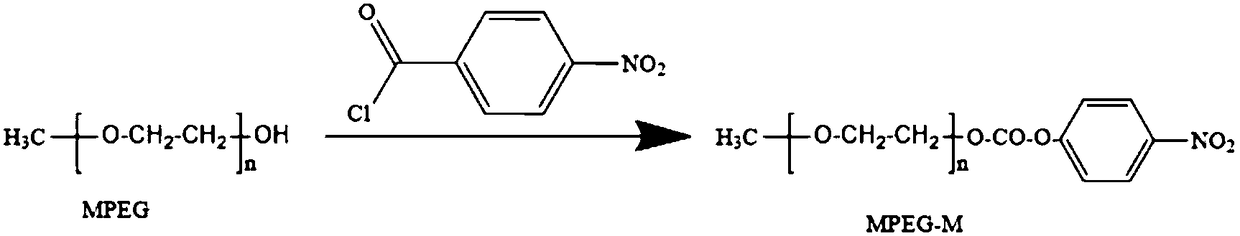

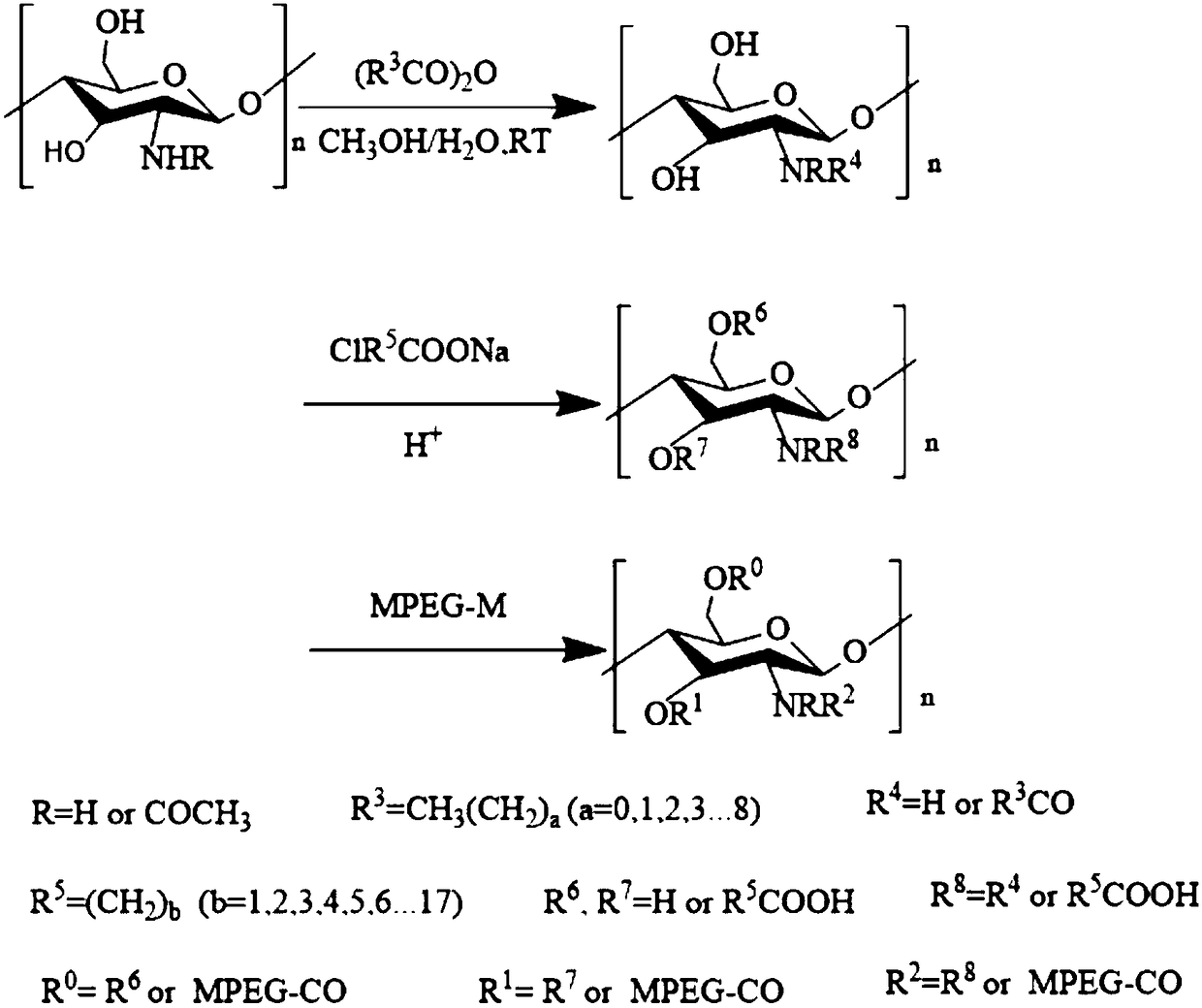

Method used

Image

Examples

Embodiment 1

[0041] Prepare the N-n-butyrylation carboxymethyl chitosan of polyethylene glycol monomethyl ether graft, concrete steps are as follows:

[0042] (1) Synthesis of N-acylated chitosan: 2g chitosan (CS) (M w =179.17kDa, degree of deacetylation >95%, viscosity 100-200mPa·s) dissolved in 40mL of 10% acetic acid aqueous solution, added 160mL of methanol to dilute, added 5.9mmol of n-butyric anhydride under stirring condition, left at room temperature for 24h, then added 260mL of acetone was used as precipitant, and the precipitate was washed three times with methanol and ether respectively, and freeze-dried to obtain white water-soluble solid N-n-butyrylated chitosan (A 4 CS).

[0043] Wherein the consumption of n-butyric anhydride is 0.5 times of the amount of amino substance contained in chitosan, and concrete calculation method is as follows:

[0044] The sugar unit of chitosan is glucosamine residue, and the molecular weight of this residue (sugar unit of chitosan) is 161, an...

Embodiment 2

[0049] Prepare the N-n-hexanoylated carboxymethyl chitosan grafted with polyethylene glycol monomethyl ether, the specific steps are as follows:

[0050] (1) Synthesis of N-acylated chitosan: 2g chitosan (CS) (M w =179.17kDa, degree of deacetylation >95%, viscosity 100-200mPa·s) dissolved in 40mL of 10% acetic acid aqueous solution, added 160mL of methanol to dilute, under stirring conditions, added 5.9mmol of n-hexanoic anhydride according to 0.5 times the amount of amino substances, and at room temperature Put 260mL acetone under the conditions and add 260mL acetone as precipitating agent, respectively wash three times through methanol and ether, lyophilize and obtain white water-soluble solid N-n-hexanoylated chitosan (A 6 CS). Wherein the calculation method of n-hexanoic anhydride consumption is described in step (1) with reference to embodiment 1.

[0051] (2) Carboxymethylation of N-n-hexanoylated chitosan: get 1.128g A 6 Add 100mL of distilled water to CS in a 250mL ...

Embodiment 3

[0055] Prepare the N-octanoyl carboxymethyl chitosan grafted with polyethylene glycol monomethyl ether, and the specific steps are as follows:

[0056] (1) Synthesis of N-acylated chitosan: 2g chitosan (CS) (M w =179.17kDa, deacetylation degree>95%, viscosity 100~200mPa·s) was dissolved in 40mL10% acetic acid aqueous solution, added 160mL methanol to dilute, under stirring condition, add n-octylic anhydride 5.9mmol according to the amount of amino substance 0.5 times, in After standing at room temperature for 24 h, 260 mL of acetone was added as a precipitating agent, and the precipitate was washed three times with methanol and ether, and freeze-dried to obtain a white water-soluble solid N-n-octanoyl chitosan (A 8 CS). Wherein the calculating method of n-octanoic anhydride consumption is described with reference to step (1) among the embodiment 1.

[0057] (2) Carboxymethylation of N-octanoyl chitosan: get 1.256g A 8 Add 100mL of distilled water to CS in a 250mL three-neck...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com