Method for measuring micro beryllium in aluminum alloy by using atomic emission spectroscopic analysis

A technology of atomic emission spectroscopy and measurement method, which is applied in the field of atomic emission spectroscopy to measure trace amounts of beryllium in aluminum alloys. It can solve problems such as the influence of third elements, many ions, and the influence of aluminum alloy structure, so as to improve the analysis sensitivity and accuracy. Effect of suppressing spectral line intensity and improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] instrument

[0034]The model of the spectrograph is QL-170, the photosensitive plate is Type I photosensitive plate, the light source is US-1, the total resistance of the light source is 78Ω, the spark resistance is 7.9Ω, the phaser is set to +6.6°, and the intermittent arc resistance is 23Ω. Spark current 4A, arc voltage 220V, arc current 12A, spark voltage 55V. The slit width is 20 μm, the lens is selected from three lenses, and the wavelength of the characteristic spectrum is selected from 220.0-280.0 nm.

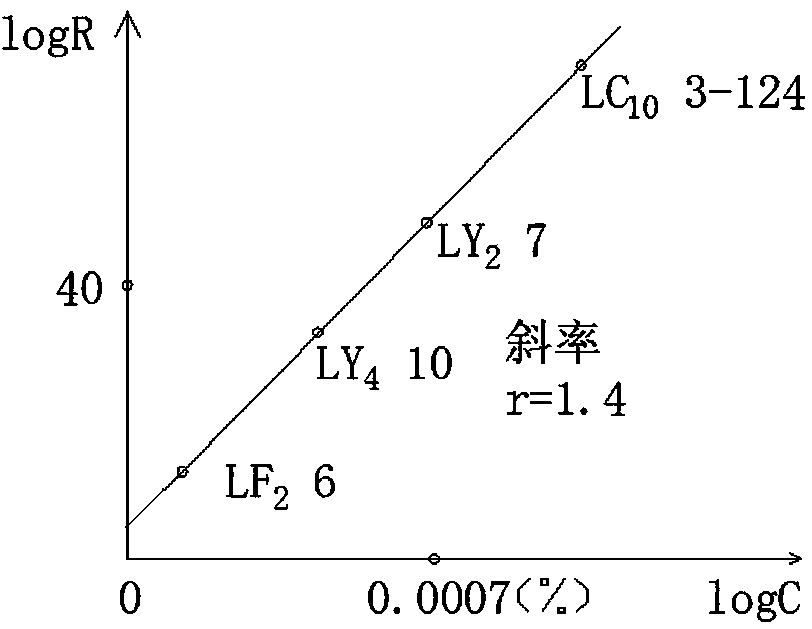

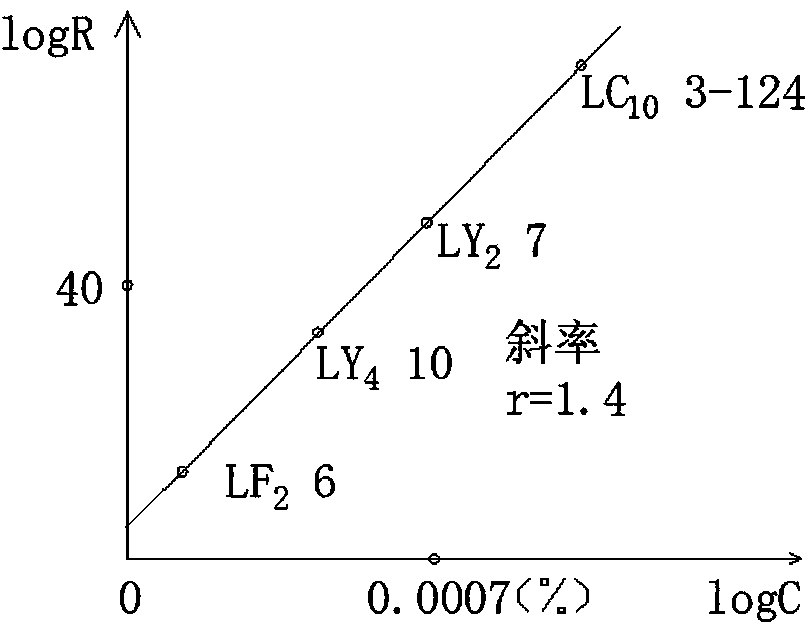

[0035] Beryllium spectral standard

[0036] LF 2 6 # , LY 2 7 # , LY 4 10 # Aluminum alloy is the procurement standard sample, among which, LF 2 6 # Anti-rust aluminum, anti-rust aluminum is Al-Mg alloy, Mg content 2.05-2.50%; LY 2 7 # It is hard aluminum, and hard aluminum is Al-Cu-Mg-Mn alloy, with Cu content of 2.70-3.10%, Mg content of 2.00-2.40%, and Mn content of 0.45-0.70%; LY 4 10 # It is hard aluminum, and hard aluminum is an Al-Cu-Mg-M...

Embodiment 2

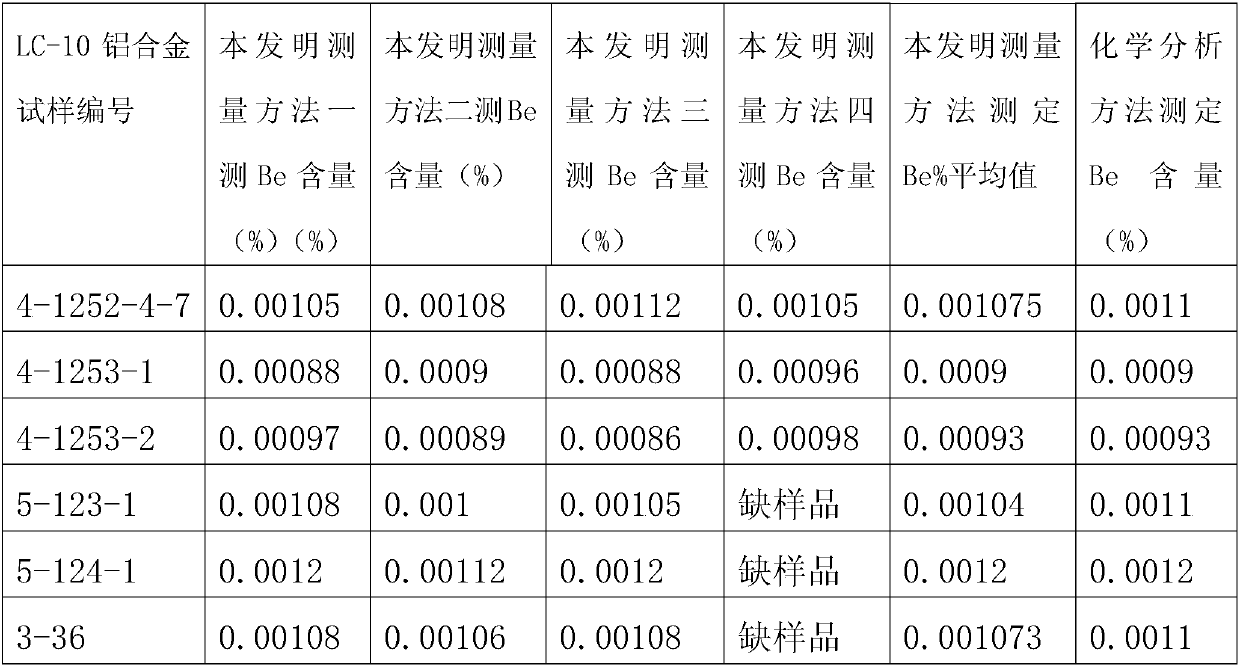

[0045] The parameters are the same as in Example 1. The upper electrode of the spectrograph is made of high-purity copper with a purity of 99.99% and processed into a flat-topped cone with a diameter of 6-8mm and a taper of 30-70°. The diameter of the discharge plane is 0.5-4.0mm. Take the LC-10 aluminum alloy sample numbered 4-1253-1 of the same specifications as the beryllium spectral standard sample as the lower electrode, and process the end face corresponding to the upper electrode into a plane by lathe. The aluminum alloy sample was clamped at the lower electrode of the spectrograph, and the spectroscopic analysis was carried out using the same spectroscopic conditions as the beryllium spectral standard sample, and the spectroscopic analysis was repeated four times.

[0046] Substituting the obtained aluminum alloy sample beryllium spectral lines into the standard curve, the calculated content of beryllium in the aluminum alloy sample is 0.00088%, 0.0009%, 0.00088%, 0.00...

Embodiment 3

[0048] The parameters are the same as in Example 1. The upper electrode of the spectrograph is made of high-purity copper with a purity of 99.99% and processed into a flat-topped cone with a diameter of 6-8mm and a taper of 30-70°. The diameter of the discharge plane is 0.5-4.0mm. Take the LC-10 aluminum alloy sample numbered 4-1253-2 of the same specifications as the beryllium spectral standard sample as the lower electrode, and process the end face corresponding to the upper electrode into a plane by lathe. The aluminum alloy sample was clamped at the lower electrode of the spectrograph, and the spectroscopic analysis was carried out using the same spectroscopic conditions as the beryllium spectral standard sample, and the spectroscopic analysis was repeated four times.

[0049] Substituting the obtained beryllium spectral lines of the aluminum alloy sample into the standard curve, the calculated content of beryllium in the aluminum alloy sample is 0.00097%, 0.00089%, 0.0008...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Taper | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Total resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com