Ceramic material with low dielectric constant and preparation method of ceramic material

A technology of low dielectric constant and ceramic materials, applied in clay products, other household utensils, applications, etc., can solve the problems of easy heat cracking, insufficient hardness, high dielectric, etc., to reduce the dielectric constant, reduce porosity, reduce Effect of sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

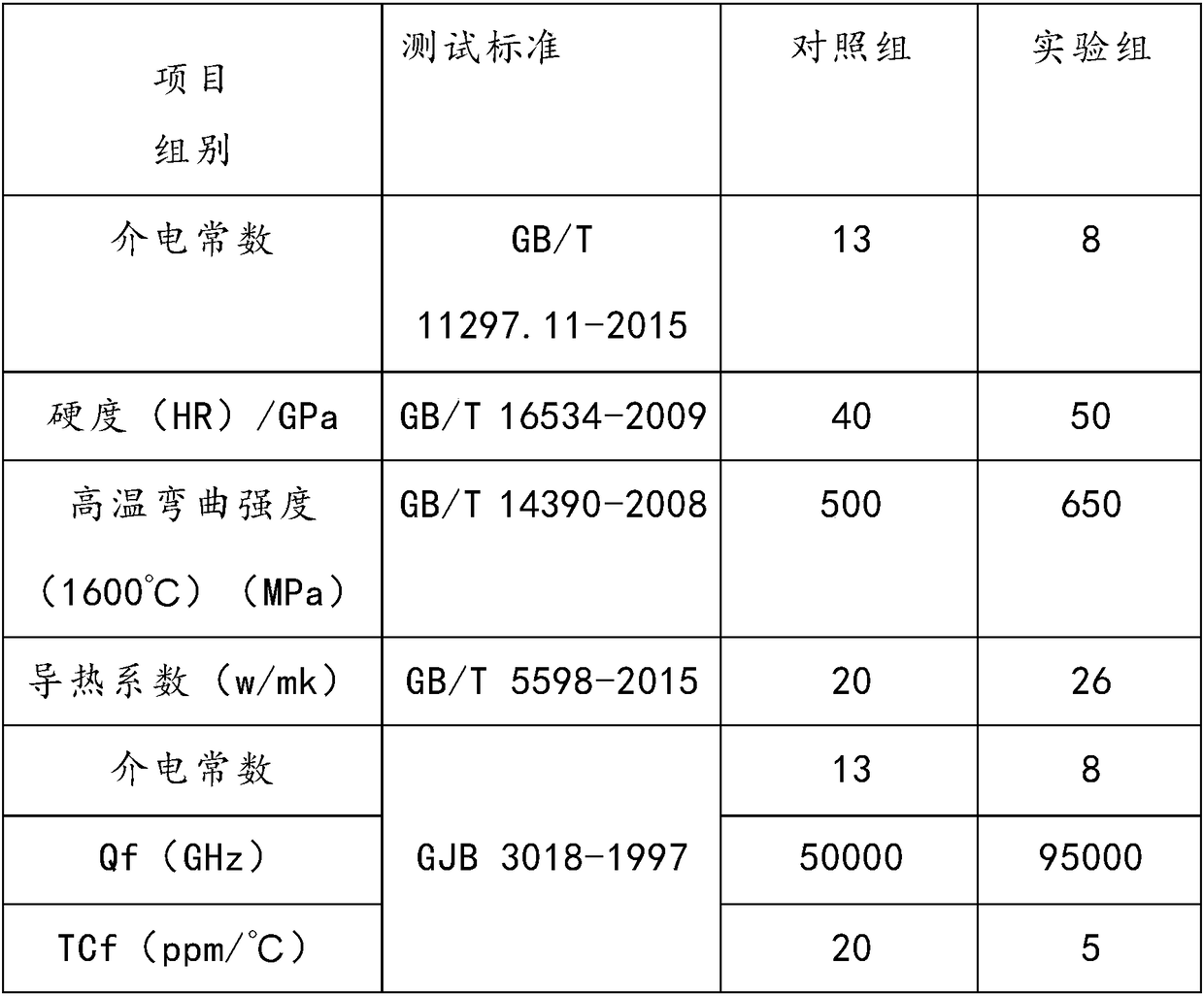

Examples

Embodiment 1

[0012] A low dielectric constant ceramic material, made of the following materials in proportion by weight: 60 parts of kaolin, 20 parts of anorthite, 17 parts of feldspar, 13 parts of sodium carboxymethyl cellulose, 11 parts of calcium titanate, 11 parts of polyvinyl alcohol, 9 parts of nano bismuth trioxide, 9 parts of boron oxide, 7 parts of zinc nitrate, 7 parts of magnesium cordierite, 6 parts of fluorite, 5 parts of tremolite, 4 parts of clinolite, 4 parts of pyrophyllite and 2 parts of yttrium aluminum garnet.

[0013] A preparation method of low dielectric constant ceramic material, comprising the following steps:

[0014] 1) Take 7 parts of magnesia cordierite, 6 parts of fluorite, 5 parts of tremolite, 4 parts of clinolite, 4 parts of pyrophyllite and 2 parts of yttrium aluminum garnet, and use a ball mill to grind it. The rotation rate of the ball mill should be 85% , the size of the powder is 3um, the pulverized powder is stirred and mixed with a mixer, the stirri...

Embodiment 2

[0023] A low dielectric constant ceramic material, made of the following materials in proportion by weight: 52 parts of kaolin, 26 parts of anorthite, 23 parts of feldspar, 17 parts of sodium carboxymethyl cellulose, 17 parts of calcium titanate, 17 parts of polyvinyl alcohol, 13 parts of nano bismuth trioxide, 13 parts of boron oxide, 11 parts of zinc nitrate, 9 parts of magnesium cordierite, 8 parts of fluorite, 7 parts of tremolite, 6 parts of clinolite, 6 parts of pyrophyllite and 4 parts of yttrium aluminum garnet.

[0024] A preparation method of low dielectric constant ceramic material, comprising the following steps:

[0025] 1) Take 9 parts of magnesium cordierite, 8 parts of fluorite, 7 parts of tremolite, 6 parts of clinolite, 6 parts of pyrophyllite and 4 parts of yttrium-aluminum garnet, and use a ball mill to grind it. The ball mill should have a rotation rate of 75% , the size of the powder is 1um, the pulverized powder is stirred and mixed with a mixer, the st...

Embodiment 3

[0034] A low dielectric constant ceramic material, made of the following materials in proportion by weight: 56 parts of kaolin, 23 parts of anorthite, 20 parts of feldspar, 15 parts of sodium carboxymethyl cellulose, 14 parts of calcium titanate, 14 parts of polyvinyl alcohol, 11 parts of nano bismuth trioxide, 11 parts of boron oxide, 9 parts of zinc nitrate, 8 parts of magnesium cordierite, 7 parts of fluorite, 6 parts of tremolite, 5 parts of clinolite, 5 parts of pyrophyllite and 3 parts of yttrium aluminum garnet.

[0035] A preparation method of low dielectric constant ceramic material, comprising the following steps:

[0036] 1) Take 8 parts of magnesium cordierite, 7 parts of fluorite, 6 parts of tremolite, 5 parts of clinolite, 5 parts of pyrophyllite and 3 parts of yttrium-aluminum garnet, and use a ball mill to crush it. The ball mill should have a rotation rate of 80% , the size of the powder is 2um, the pulverized powder is stirred and mixed with a mixer, the sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com