Production process of chopped basalt fibers

A chopped fiber and production process technology, which is applied in the field of surface modification of inorganic materials, can solve the problems of increased production troubles and costs, product performance fluctuations, increased production costs, etc., achieve high uniformity of heating, save power consumption, and save electricity bills Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

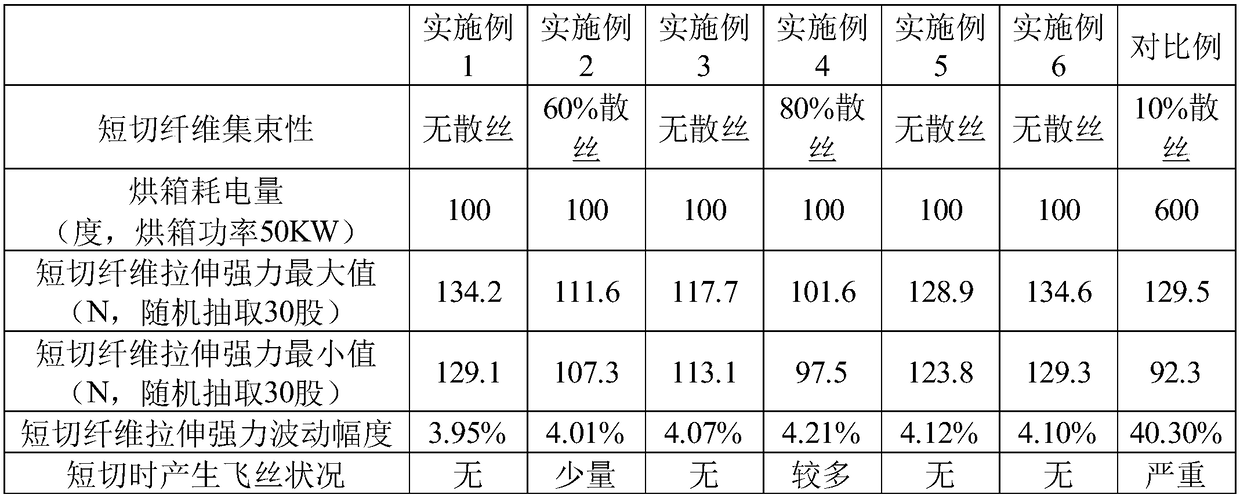

Examples

Embodiment 1

[0025] A basalt chopped fiber production process,

[0026] 1.1) Continuous fiber step: the fiber raw material is melted in a furnace, and the temperature of the furnace is 1500° C. for melting. The fiber raw material in the molten state flows out of the furnace body through the bushing plate. The temperature of the bushing plate is 1390°C. Then, it is drawn by the wire drawing machine with a line speed of 1000m / min. The sizing agent is completely covered by the oiler. The line speed is 50m / min. Then, it is plied by the bundle wheel and arranged by the wire unwinder, and then drawn and wound on the take-up drum to obtain continuous fibers. The sizing agent is composed of the following components in terms of mass percentage: film-forming agent (polyurethane emulsion) 0.5-25%, coupling agent (γ-aminopropyltriethoxysilane) 0.1-1.5%, lubricant (propylene glycol front stage) polyether) 0.01-1.5%, antistatic agent (lithium nitrate) 0.1-1.5%, fiber monofilament dispersant 0.1-5%, an...

Embodiment 2

[0032] A production process of basalt chopped fiber. It is the same as Example 1 except the following:

[0033]Prepare 4kg chopped lubricant (add 3997.2g deionized water in the preparation tank, stirring speed 120r / min, add 2g polyvinyl alcohol, 0.4g coconut oil fatty acid diethanolamide, 0.4g acetylene glycol again, stir 3min Can).

Embodiment 3

[0035] A production process of basalt chopped fiber. It is the same as Example 1 except the following:

[0036] Prepare 4kg of chopped lubricant (add 3944g of deionized water to the preparation tank, stir at a speed of 120r / min, add 40g of polyvinyl alcohol, 8g of coconut oil fatty acid diethanolamide, 8g of acetylene glycol, and stir for 3 minutes).

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com