Metal grid touch screen and preparation process thereof

A metal grid and touch screen technology, applied in the direction of instruments, electrical digital data processing, data processing input/output process, etc., can solve the problems of complex preparation process, low reflectivity, low reflectivity, etc., and achieve simple process technology, Low reflectivity, effect of reducing reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

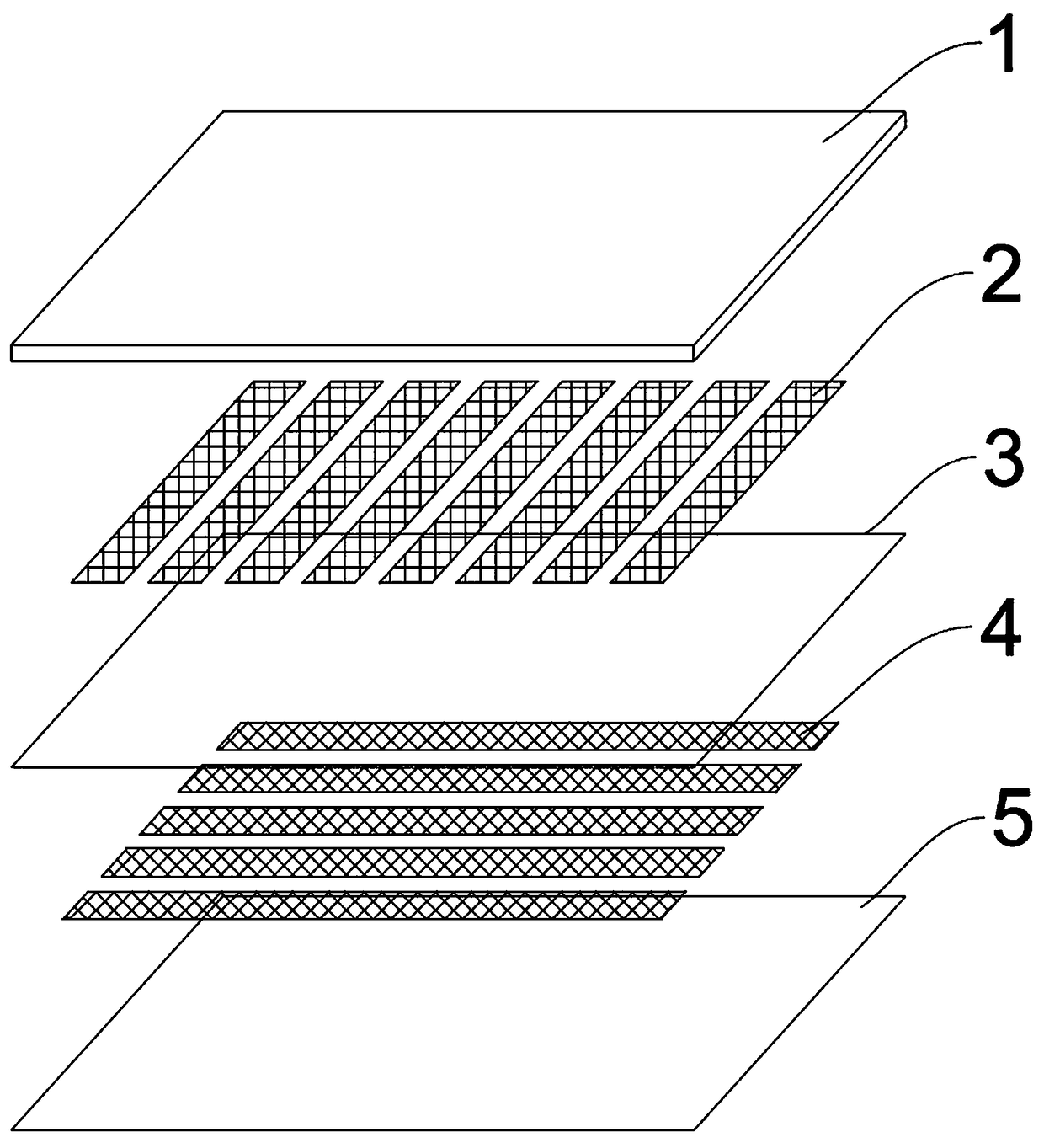

[0062] Such as figure 1 As shown, the metal grid touch screen provided in this embodiment includes sequentially arranged: a glass substrate 1, a first blackened Cu alloy grid layer 2, an OC insulating layer 3, and a second blackened Cu alloy grid layer. Cu alloy grid layer 4, OC protection layer 5, wherein,

[0063] The first blackened Cu alloy grid layer 2 contains copper oxide and copper nitride, and contains aluminum oxide;

[0064] The second blackened Cu alloy grid layer 4 contains copper oxide, copper nitride, and aluminum oxide.

[0065] The preparation process of the metal grid touch screen is as follows:

[0066] S100: Coating the first blackened Cu alloy layer on the glass substrate 1, the square resistance of the film layer is lower than 10Ω; wherein, the specific coating atmosphere is 55 vol.% nitrogen + 9 vol.% oxygen + 36 vol.% argon Composed of a mixed gas, the plating target is a Cu alloy, the composition of the Cu alloy is: copper 95wt.%, aluminum 5wt.%;

...

Embodiment 2

[0073] A metal grid touch screen provided in this embodiment, the metal grid touch screen includes: a plastic substrate, a first blackened Cu alloy grid layer, an OC insulating layer, a second blackened Cu alloy grid layer, OC protection layer, where,

[0074] The first blackened Cu alloy grid layer contains copper oxide and copper nitride, and contains zinc oxide;

[0075] The second blackened Cu alloy grid layer contains copper oxide, copper nitride, and zinc oxide.

[0076] The preparation process of the metal grid touch screen is as follows:

[0077] S100: Coating the first blackened Cu alloy layer on the plastic substrate, the film layer resistance is lower than 10Ω; wherein, the specific coating atmosphere is 57 vol.% nitrogen + 7 vol.% oxygen + 36 vol.% argon Composed of mixed gas, the plating target is a Cu alloy, the composition of the Cu alloy is: copper 92wt.%, zinc 8wt.%;

[0078] S200: Etching the plated first blackened Cu alloy layer by a conventional etching ...

Embodiment 3

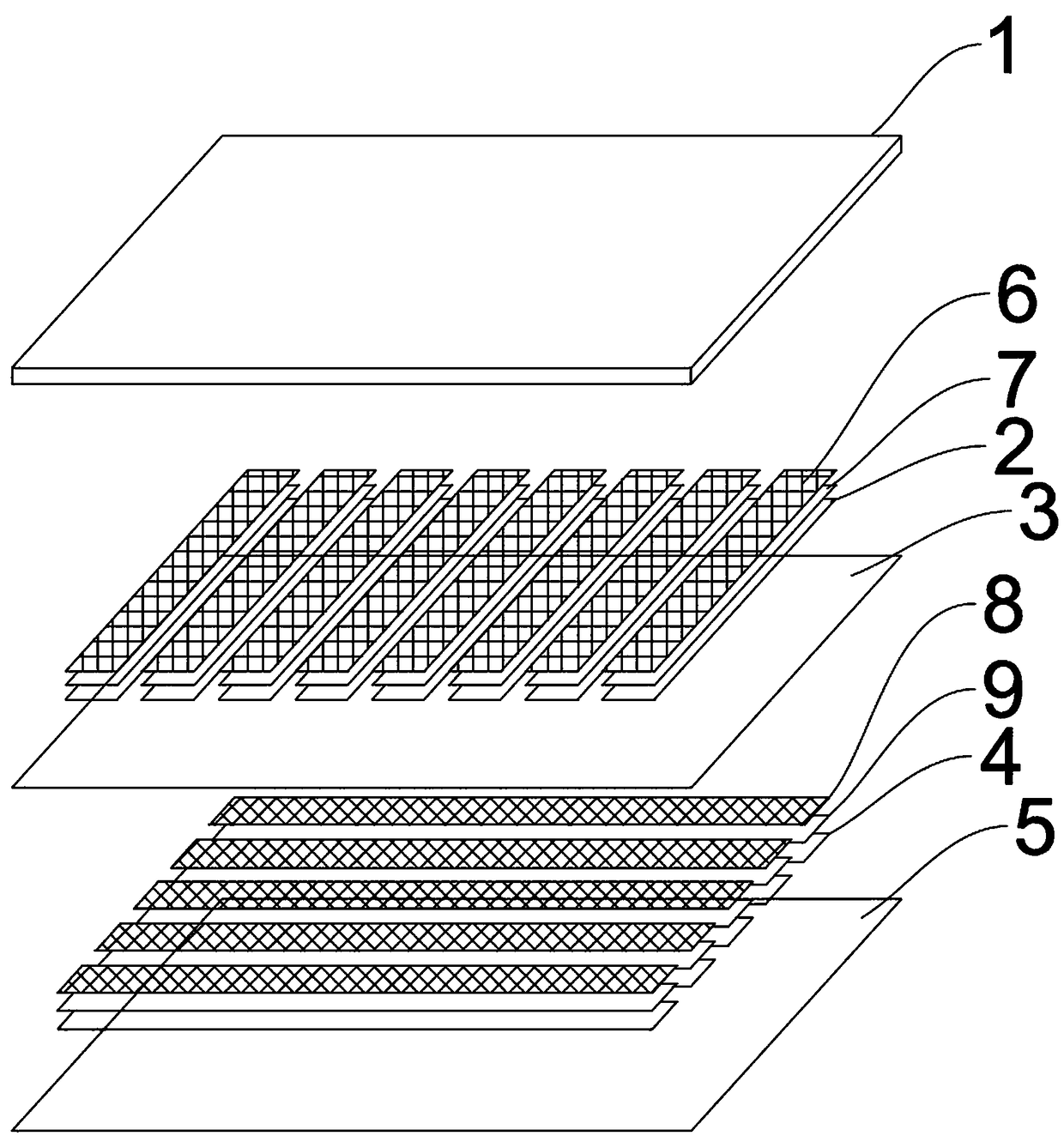

[0084] Such as figure 2 As shown, a metal grid touch screen provided in this embodiment includes sequentially arranged: a glass substrate 1, a third blackened Cu alloy grid layer 6, a first Cu grid layer 7, and a first blackened Cu alloy grid layer. Grid layer 2, OC insulating layer 4, fourth blackened Cu alloy grid layer 8, second Cu grid layer 9, second blackened Cu alloy grid layer 4, OC protective layer 5; wherein:

[0085] The first blackened Cu alloy grid layer 2 contains copper oxide, copper nitride, aluminum oxide, and zinc oxide;

[0086] The second blackened Cu alloy grid layer 4 contains copper oxide, copper nitride, aluminum oxide, and zinc oxide;

[0087] The third blackened Cu alloy grid layer 6 contains copper oxide, aluminum oxide, and zinc oxide; the fourth blackened Cu alloy layer 8 contains copper oxide, aluminum oxide, and zinc oxide;

[0088] The preparation process of the metal grid touch screen is as follows:

[0089] S101: Coating the third blackene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com