Alginate-drug loaded nanoparticle-polycation microcapsule and preparation and application thereof

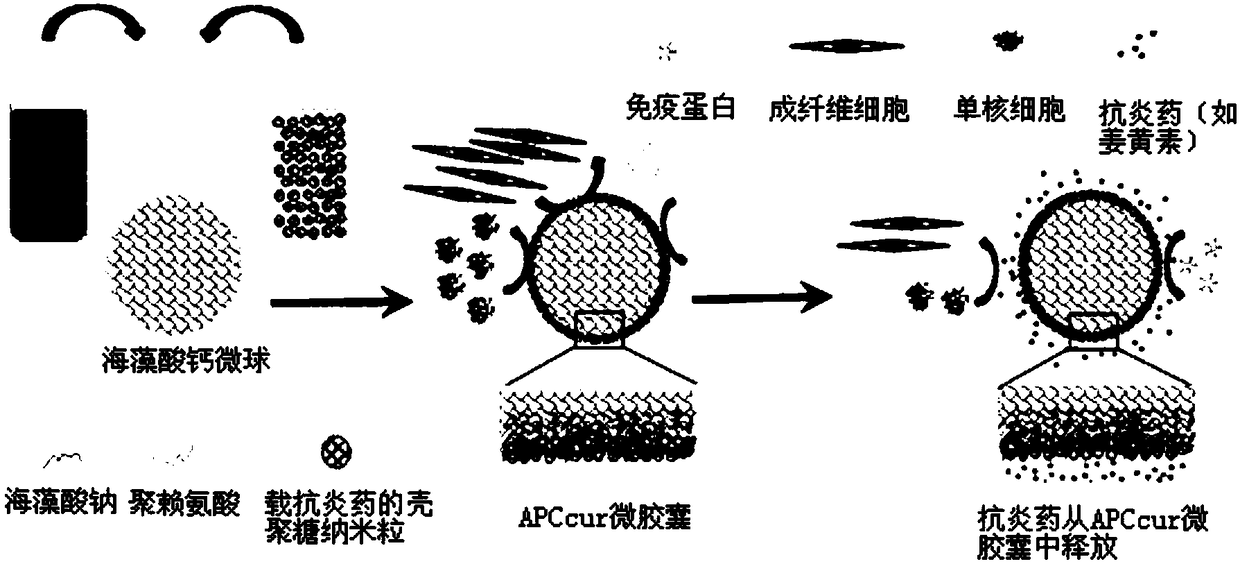

A technology of alginate and polycation, which is applied in the direction of antipyretics, drug combinations, and pharmaceutical formulas, and can solve the problem that metabolites in the capsule cannot diffuse out of the capsule, affecting the transfer of nutrients and metabolites, nutrients and oxygen supply Insufficient and other problems, to achieve superior immune isolation performance, maintain immune isolation performance, and avoid the effect of host immune response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The amphiphilic chitosan material with a hydrophobic substitution degree of 4.5 and a cationic hydrophilic group substitution degree of 60 was prepared.

[0048] Cationic amphiphilic chitosan nanoparticles loaded with curcumin were prepared under sterile conditions.

[0049] Calcium alginate gel microspheres were prepared by high voltage electrostatic method under sterile conditions.

[0050] Immerse the microspheres in the polylysine solution (polylysine molecular weight 20kDa, the solution is prepared from physiological saline, the concentration is 0.5g / L), the volume ratio of microspheres and polylysine solution is 1:10, react for 5 minutes, Wash with saline three times.

[0051] Step 3) The prepared microspheres were then immersed in the curcumin-loaded cationic amphiphilic chitosan nanoparticle solution prepared in step 1), the volume ratio of the microspheres to the nanoparticle solution was 1:10, and the reaction was performed for 10 minutes. Wash three times. ...

Embodiment 2

[0067] The reference method was used to prepare hydrophobically modified amphiphilic sodium alginate materials.

[0068] The solution of amphiphilic sodium alginate nanoparticles loaded with curcumin was prepared under sterile conditions.

[0069] Calcium alginate gel microspheres embedded with porcine hepatocytes were prepared by orifice extrusion method, and the cell content in the microspheres was 5×107 / ml microspheres.

[0070] Immerse the microspheres in polylysine solution successively (polylysine molecular weight is 20kDa, the solution is prepared by physiological saline, the concentration is 0.5g / L), the volume ratio of microspheres and polylysine solution is 1:10, react for 10 minutes , washed three times with saline.

[0071] The microspheres prepared in step 4) were immersed in the curcumin-loaded amphiphilic sodium alginate nanoparticle solution prepared in step 2), the volume ratio of the microspheres to the nanoparticle solution was 1:10, reacted for 15 minutes,...

Embodiment 3

[0075] The amphiphilic chitosan material with a hydrophobic substitution degree of 3.5 and a cationic hydrophilic group substitution degree of 62 was prepared.

[0076] Cationic amphiphilic chitosan nanoparticle solution loaded with curcumin was prepared under sterile conditions.

[0077] Calcium alginate gel microspheres embedded with porcine islet cells were prepared by high-voltage electrostatic method, and each microsphere contained 1-2 islets.

[0078] With the method of embodiment 1, microsphere is successively immersed in polylysine solution (polylysine molecular weight 20kDa, and solution is prepared by physiological saline, concentration 0.5g / L), and the cationic amphipathic chitopolymer of loading curcumin In the sugar nanoparticle solution, react with 0.2% sodium alginate solution for 10 minutes after the secondary film-forming reaction, wash with normal saline, liquefy 55mM sodium citrate, wash with normal saline, and prepare APCcur microparticles embedded with isl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com