Method for preparing organo-silicon polymer luminescent material and application of organo-silicon polymer luminescent material to OLED device

A technology of light-emitting materials and polymers, applied in the fields of light-emitting materials, chemical instruments and methods, can solve the problems of poor stability of organic light-emitting materials, limited light-emitting wavelength range, low comprehensive light-emitting efficiency, etc. Yoke system, effect of good rollability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

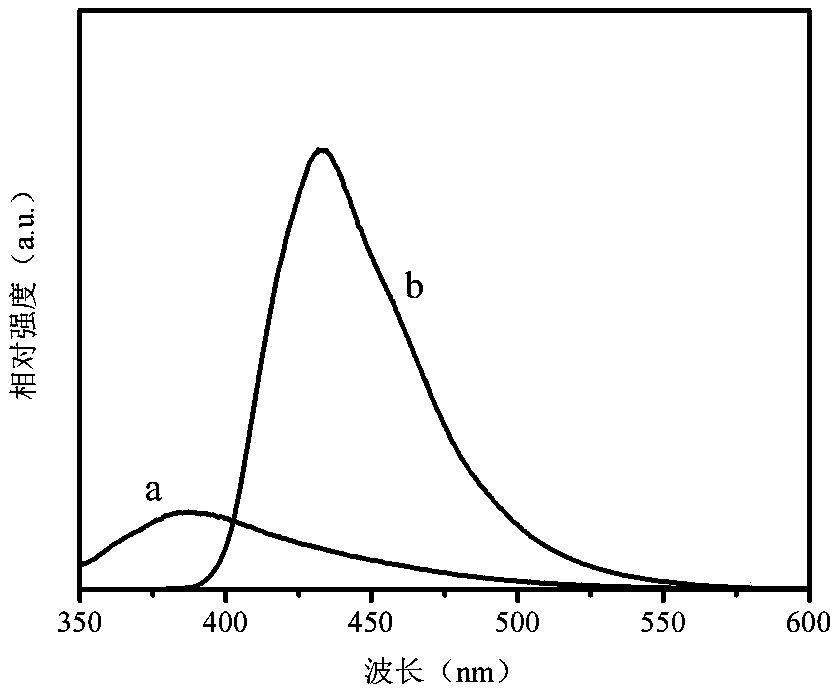

[0032] The preparation method embodiment of the organosilicon polymer luminescent material comprises the following steps:

[0033] The organosilicon polymer luminescent material is a PCS luminescent material containing anthracene groups in the side chain, and its general structural formula is as follows:

[0034]

[0035] Dissolve the ground PCS and 9-vinyl anthracene in xylene respectively, and add a catalyst to the xylene solution of 9-vinyl anthracene. After activation, mix the PCS and 9-vinyl anthracene solution into a container In the middle; set the temperature rise program, keep warm under an inert gas atmosphere, and react, and let the whole system cool down to room temperature naturally after the reaction; carry out negative pressure rotary distillation on the mixed solution after the reaction to remove the solvent to obtain a light yellow solid, and then After drying, the organosilicon polymer luminescent material is obtained.

[0036] The catalyst catalyst can b...

Embodiment 1

[0041] Preparation of PCS luminescent material with anthracene group in side chain:

[0042] (1) Weigh 3g of PCS, dissolve it in 30mL of xylene, and place the solution in a three-necked flask to check its airtightness. Then, the synthesis device was evacuated for 3 times with a vacuum pump, and the whole system was placed in an argon atmosphere protection environment.

[0043] (2) Weigh 0.5g of 9-vinylanthracene, dissolve it in 30mL of xylene, and drop into 1mL of H 2 PtCl 6 Catalyst, activation treatment about 30min.

[0044] (3) Slowly drop the above-mentioned 9-vinylanthracene solution into the three-necked flask of the synthesis device through the dropping funnel. Under magnetic stirring, allow the solution to mix thoroughly.

[0045] (4) After the reaction starts, a certain flow rate of argon gas should be maintained. Heating program: from room temperature to 80°C, the heating rate is 5°C / min, and the synthesis time is 2h. After the reaction, the whole system was na...

Embodiment 2

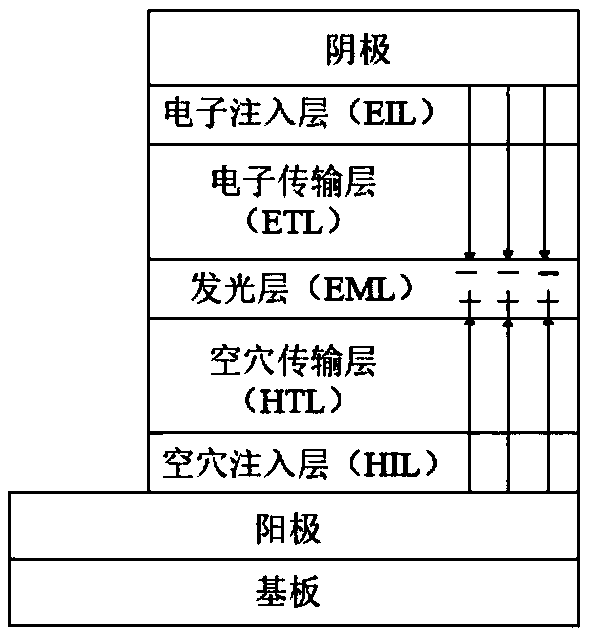

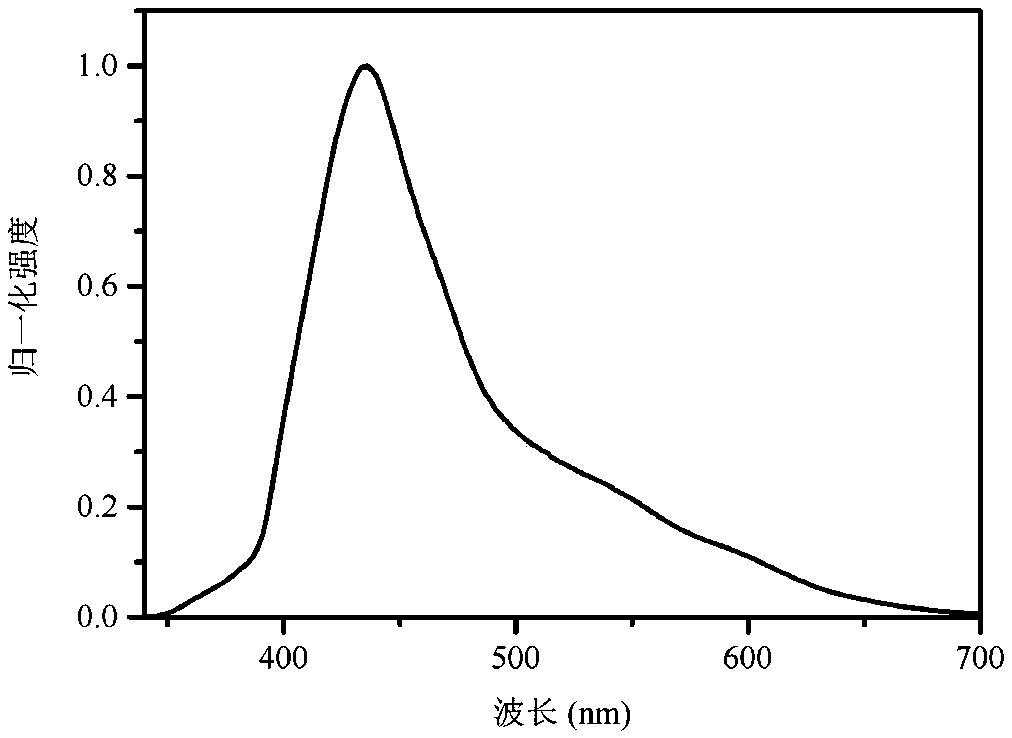

[0051] Fabrication of OLED devices:

[0052] (1) Cleaning of the anode ITO (indium tin oxide) substrate: a) Clean the cut ITO glass with a glass cleaner; b) Ultrasonic clean it with distilled water, acetone, and isopropanone for 10 minutes; c) Clean it with N 2 After drying, it was treated with ultraviolet ozone for 10 minutes.

[0053] (2) Preparation of hole transport layer: a) Spin-coat a layer of polyethylenedioxythiophene-poly(styrenesulfonic acid) (PEDOT:PSS) film on the surface of ITO glass with a thickness of 40nm; b) Quenching at 140°C 20min; c) After cooling to room temperature, spin-coat a layer of poly(9,9-dioctylfluorene-CO-N-(4-butylphenyl)diphenylamine) (TFB) on the film with toluene as solvent , with a thickness of 10nm; d) Quenching at 200°C for 20min.

[0054] (3) Preparation of the light-emitting layer: a) The anthracene-containing organosilicon polymer light-emitting material prepared above and the BCPO host material were co-dissolved in dichloromethane a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| luminance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com