A kind of preparation method of carbon fiber interface

A technology of carbon fiber preform and carbon fiber, which is applied in the field of carbon fiber interface preparation, can solve the problems of composite material strength reduction, high preparation temperature, and long preparation time, and achieve the effects of improving fracture toughness, solving toughness decline, and improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

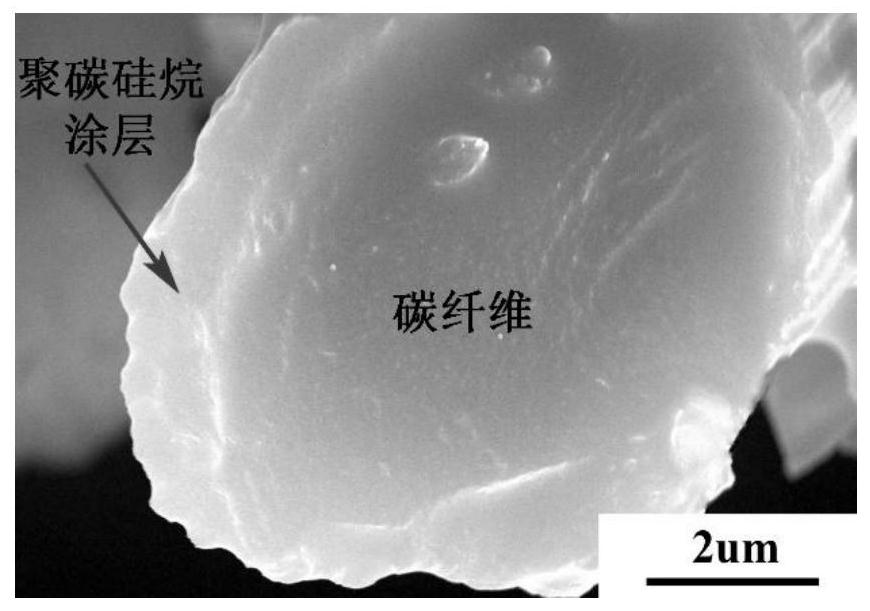

Image

Examples

Embodiment 1

[0020] Preparation of interface solution: dissolve polycarbosilane in xylene, the mass ratio of polycarbosilane to xylene is 1:10;

[0021] Vacuum pressure impregnation: Put the carbon cloth (Toray T300 1K plain weave) and the interface solution in a vacuum tank at the same time, vacuumize at -0.08MPa~-0.10MPa for 20 minutes, then slowly pressurize, and raise the air pressure to 0.8MPa, Hold for 30 minutes;

[0022] Drying and curing: After taking out the carbon cloth, cool it at room temperature for 3-10 hours, cure it in an oven at 120°C-130°C for 2-5 hours, cure it at 140-160°C for 2-5 hours, and cure it at 180-200°C 2 to 5 hours;

[0023] Prepare phenolic resin solution: dissolve phenolic resin and hexamethylenetetramine in absolute ethanol, the quality of hexamethylenetetramine is 10% of the quality of phenolic resin, and control the viscosity of the solution by controlling the content of absolute ethanol to be 50- 100mPa·s;

[0024] Vacuum pressure impregnation: put t...

Embodiment 2

[0027] Preparation of interface solution: dissolve polycarbosilane in xylene, the mass ratio of polycarbosilane to xylene is 1:10;

[0028] Vacuum pressure impregnation: Put the carbon cloth (Toray T300 1K plain weave) and the interface solution in a vacuum tank at the same time, vacuumize at -0.08MPa~-0.10MPa for 20 minutes, then slowly pressurize, and raise the air pressure to 0.8MPa, Hold for 30 minutes;

[0029] Drying and curing: After taking out the carbon cloth, cool it at room temperature for 3-10 hours, cure it in an oven at 120°C-130°C for 2-5 hours, cure it at 140-160°C for 2-5 hours, and cure it at 180-200°C 2 to 5 hours;

[0030] Preparation of boron-modified phenolic resin solution: dissolving boron-modified phenolic resin in absolute ethanol, controlling the viscosity of the solution to 50-100 mPa·s by controlling the content of absolute ethanol;

[0031] Vacuum pressure impregnation: put the prepared carbon cloth and resin solution in the vacuum tank at the s...

Embodiment 3

[0034] Preparation of interface solution: dissolve polycarbosilane in xylene, the mass ratio of polycarbosilane to xylene is 1:10;

[0035] Vacuum pressure impregnation: Put the carbon cloth (Toray T300 1K plain weave) and the interface solution in a vacuum tank at the same time, vacuumize at -0.08MPa~-0.10MPa for 20 minutes, then slowly pressurize, and raise the air pressure to 0.8MPa, Hold for 30 minutes;

[0036] Drying and curing: After taking out the carbon cloth, cool it at room temperature for 3-10 hours, cure it in an oven at 120°C-130°C for 2-5 hours, cure it at 140-160°C for 2-5 hours, and cure it at 180-200°C 2 to 5 hours;

[0037] Preparation of boron-modified resin slurry: Dissolve boron-modified phenolic resin in absolute ethanol, add borosilicate glass powder to it after fully dissolving, the mass ratio of powder to resin is 10-40%, through controlling absolute ethanol The viscosity of the content control solution is 50-100mPa·s;

[0038] Vacuum pressure impr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com