A treatment method for reducing warping of electrolytic copper foil

A treatment method, electrolytic copper foil technology, applied in electrolytic process, electroforming, metal material coating process, etc., can solve the problem of destroying crystal symmetry, achieve excellent oxidation resistance, realize warping, and increase anti-peeling strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A treatment method for reducing warpage of electrolytic copper foil, the steps are as follows:

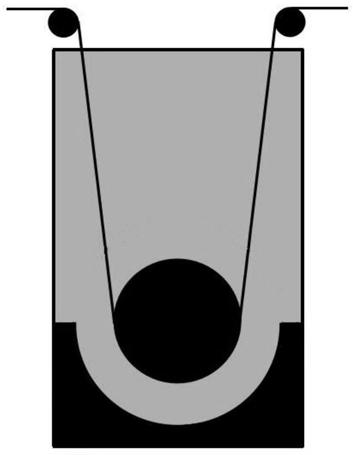

[0035] 1) Using 18μm HTE copper foil as the original foil, the diameter of the submerged transmission guide roller is 40cm, concentric arc-shaped titanium anode, and the pole distance is 5cm;

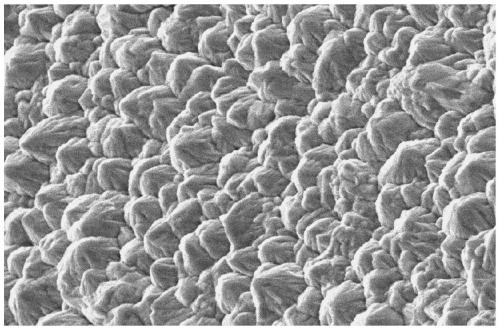

[0036] 2) Special roughening: The 18μm HTE original foil after pickling is subjected to special roughening treatment, the specific process conditions are: CuSO 4 ·5H 2 O 60g / L, H 2 SO 4 220g / L, additive 12g / L, temperature 30°C, current density 35A / dm 2 , time 2.7s;

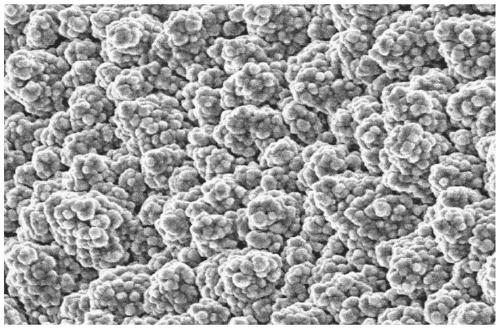

[0037] 3) Special curing: the copper foil obtained in step 2) is subjected to special curing treatment, and the process conditions are: CuSO 4 ·5H 2 O240g / L, H 2 SO 4 130g / L, protein powder 18ppm, hydroxyethyl cellulose 10ppm, sodium polydithiodipropane sulfonate 5ppm, temperature 45°C, current density 20A / dm 2 , time 2.7s;

[0038] 4) roughening: the copper foil obtained in step 3) is roughened, and the proce...

Embodiment 2

[0044] A treatment method for reducing warpage of electrolytic copper foil, the steps are as follows:

[0045] 1) Use 18μm HTE copper foil as the original foil, the diameter of the submerged transmission guide roller is 50cm, concentric arc-shaped titanium anode, and the pole distance is 5cm;

[0046] 2) Special roughening: The 18μm HTE raw foil after pickling is subjected to special roughening treatment, and the process conditions are: CuSO 4 ·5H 2 O 90g / L, H 2 SO 4 200g / L, additive 9g / L, temperature 40°C, current density 20A / dm 2 , time 3.5s;

[0047] 3) Special curing: the copper foil obtained in step 2) is subjected to special curing treatment, and the process conditions are: CuSO 4 ·5H 2 O220g / L, H 2 SO 4 140g / L, 25ppm protein powder, 12ppm hydroxyethyl cellulose, 3.4ppm sodium polydithiodipropane sulfonate, temperature 45°C, current density 15A / dm 2 , time 3.5s;

[0048] 4) The copper foil obtained in step 3) is subjected to roughening, curing, galvanized nic...

Embodiment 3

[0050] A treatment method for reducing warpage of electrolytic copper foil, the steps are as follows:

[0051] 1) Using 18μm HTE copper foil as the original foil, the diameter of the submerged transmission guide roller is 30cm, concentric arc-shaped titanium anode, and the pole distance is 5cm;

[0052] 2) Special roughening: The 18μm HTE raw foil after pickling is subjected to special roughening treatment, and the process conditions are: CuSO 4 ·5H 2 O 110g / L, H 2 SO 4 170g / L, additive 15g / L, temperature 50℃, current density 35A / dm 2 , time 4.2s;

[0053] 3) Special curing: the copper foil obtained in step 2) is subjected to special curing treatment, and the process conditions are: CuSO 4 ·5H 2 O290g / L, H 2 SO 4 120g / L, protein powder 30ppm, hydroxyethyl cellulose 6ppm, sodium polydithiodipropane sulfonate 1.6ppm, temperature 45°C, current density 30A / dm 2 , time 4.2s;

[0054] 4) The copper foil obtained in step 3) is subjected to roughening, curing, zinc-nickel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com