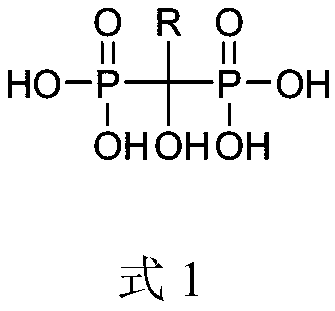

Application of organic phosphoric acid type compound to mineral flotation

A mineral flotation and compound technology, used in flotation, solid separation, etc., can solve the problems of low recovery rate of scheelite concentrate, substandard products, poor selective inhibition ability of water glass, etc., and achieve excellent flotation effect. , Improve the recovery rate and taste, the selective inhibition effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

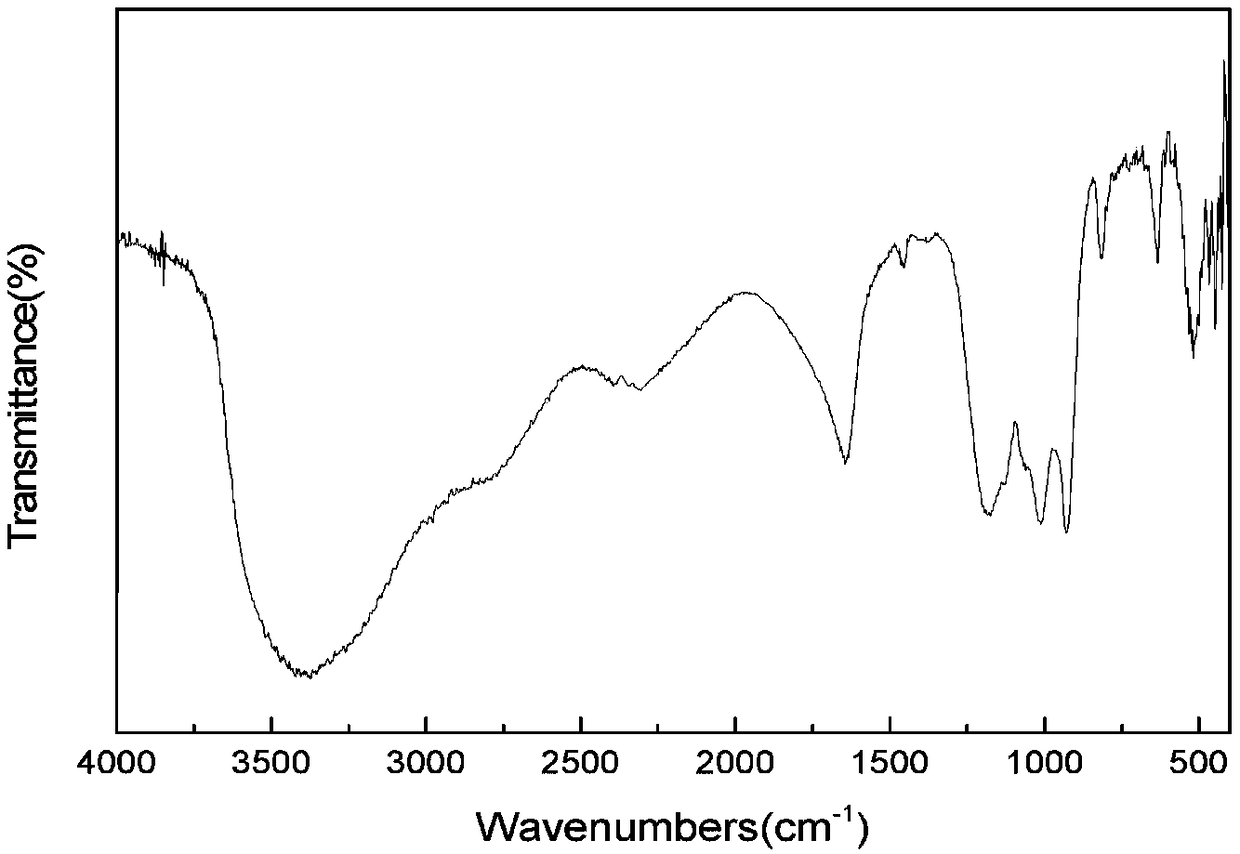

[0053] The acetic acid of 34.0g and the deionized water of 18.0g are added in the four-necked 250ml flask that stirrer, thermometer, condenser tube and dropping funnel are equipped with, start to stir; During the addition process, use a cold water bath to control the reaction temperature not higher than 35°C; after dropping phosphorus trichloride, raise the temperature to 50-60°C for constant temperature esterification reaction, the reaction time is 20min; after the reaction is completed, slowly raise the temperature to 100-60°C 120°C, reflux for 4 hours; after the reaction, pass water vapor for hydrolysis reaction for 6 hours, and steam the residual acetic acid and low boiling point substances, and the rest is the organic phosphoric acid compound inhibitor. The infrared spectrum of the inhibitor is shown in figure 1 shown.

[0054] The obtained organophosphate compound inhibitor was applied to the flotation of a certain scheelite in Hunan, which is a typical scheelite-calcit...

Embodiment 2

[0060] The acetic acid of 34.0g and the deionized water of 18.0g are added in the four-necked 250ml flask that stirrer, thermometer, condenser tube and dropping funnel are equipped with, start to stir; During the addition process, use a cold water bath to control the reaction temperature not higher than 35°C; after dropping phosphorus trichloride, raise the temperature to 50-60°C for constant temperature esterification reaction, the reaction time is 20min; after the reaction is completed, slowly raise the temperature to 100-60°C 120°C, reflux for 4 hours; after the reaction, pass water vapor for hydrolysis reaction for 6 hours, and steam the residual acetic acid and low boiling point substances, and the rest is the organic phosphoric acid compound inhibitor. The infrared spectrum of the inhibitor is shown in figure 1 shown.

[0061] The obtained organophosphate compound inhibitor was applied to the flotation of a scheelite ore in Henan. The ore is scheelite-calcite type ore, ...

Embodiment 3

[0068] The acetic acid of 34.0g and the deionized water of 18.0g are added in the four-necked 250ml flask that stirrer, thermometer, condenser tube and dropping funnel are equipped with, start to stir; During the addition process, use a cold water bath to control the reaction temperature not higher than 35°C; after dropping phosphorus trichloride, raise the temperature to 50-60°C for constant temperature esterification reaction, the reaction time is 20min; after the reaction is completed, slowly raise the temperature to 100-60°C 120°C, reflux for 4 hours; after the reaction, pass water vapor for hydrolysis reaction for 6 hours, and steam the residual acetic acid and low boiling point substances, and the rest is the organic phosphoric acid compound inhibitor. The infrared spectrum of the inhibitor is shown in figure 1 shown.

[0069] The obtained organophosphate compound inhibitor was applied to the flotation of a scheelite ore in Jiangxi. The ore is scheelite-fluorite type or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com