An LED chip with an ultraviolet through-hole structure of a multifunctional reflector and a preparation method thereof

A technology for LED chips and LED epitaxial wafers, applied in semiconductor devices, electrical components, circuits, etc., can solve problems such as unguaranteed process accuracy, high cost of precious metal materials, and inability to align holes, saving manufacturing costs and achieving uniform current distribution. The effect of improving the performance and increasing the current distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] A method for preparing an LED chip with an ultraviolet through-hole structure of a multifunctional reflector, comprising:

[0074] LED epitaxial wafer growth step: provide an epitaxial substrate, epitaxially grow LED epitaxial wafers on the epitaxial substrate, LED epitaxial wafers include n-type doped GaN films grown on epitaxial substrates, and n-type doped GaN films grown on n-type doped GaN films InGaN / GaN multiple quantum wells, p-type doped GaN films grown on InGaN / GaN quantum wells, epitaxial growth substrates are Si substrates, GaN substrates, sapphire substrates, LSAT substrates or LiGaO 2 A substrate, wherein the Si substrate (111) plane is an epitaxial plane;

[0075] CBL patterning processing steps: patterning the surface of the p-type doped GaN film with standard photolithography and inductively coupled plasma etching. O 2 As a reactive gas, it achieves the effect of forming a Schottky contact, which can improve the current congestion phenomenon, thereby in...

Embodiment 2

[0086] A method for preparing an LED chip with an ultraviolet through-hole structure of a multifunctional reflector, comprising:

[0087] LED epitaxial wafer growth step: provide an epitaxial substrate, epitaxially grow LED epitaxial wafers on the epitaxial substrate, LED epitaxial wafers include n-type doped GaN films grown on epitaxial substrates, and n-type doped GaN films grown on n-type doped GaN films InGaN / GaN multiple quantum wells, p-type doped GaN films grown on InGaN / GaN quantum wells, epitaxial growth substrates are Si substrates, GaN substrates, sapphire substrates, LSAT substrates or LiGaO 2 A substrate, wherein the Si substrate (111) plane is an epitaxial plane;

[0088] CBL patterning processing steps: patterning the surface of the p-type doped GaN film with standard photolithography and inductively coupled plasma etching. The power of the etched upper electrode is 900W, and the power of the lower electrode is 500W. O 2 As a reactive gas, it achieves the effe...

Embodiment 3

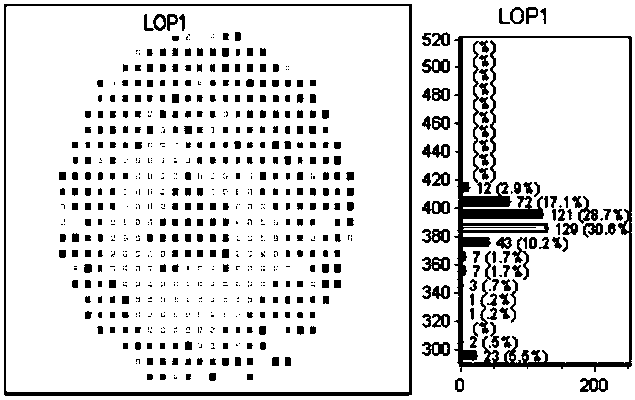

[0099] refer to Figure 1-12 , a method for preparing an LED chip with an ultraviolet through-hole structure of a multifunctional reflector, comprising,

[0100] LED epitaxial wafer growth step: provide an epitaxial substrate, epitaxially grow LED epitaxial wafers on the epitaxial substrate, LED epitaxial wafers include n-type doped GaN thin film 101 grown on the epitaxial substrate, grown on n-type doped GaN thin film 101 InGaN / GaN multiple quantum wells 102 on the InGaN / GaN quantum wells, p-type doped GaN film 103 grown on the InGaN / GaN quantum wells, the epitaxial growth substrate 100 is Si substrate, GaN substrate, sapphire substrate, LSAT substrate or LiGaO 2 A substrate, wherein the Si substrate (111) plane is an epitaxial plane;

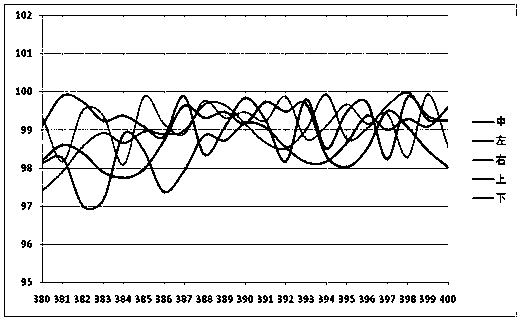

[0101] CBL patterning 104 processing steps: patterning the surface of the p-type doped GaN film 103 with the standard photolithography process and inductively coupled plasma etching method, the etching power of the upper electrode is 500W, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com