Thermoplastic elastomer halogen-free flame retardant cable material for external use and preparation method thereof

A technology of thermoplastic elastomers and thermoplastic polyurethanes, applied in the direction of plastic/resin/wax insulators, insulators, organic insulators, etc., can solve problems such as short service life, decreased material flexibility, and weakened thermoplasticity and elasticity of filling materials. Improve the effect of thermoplasticity, strict ratio and scientific formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

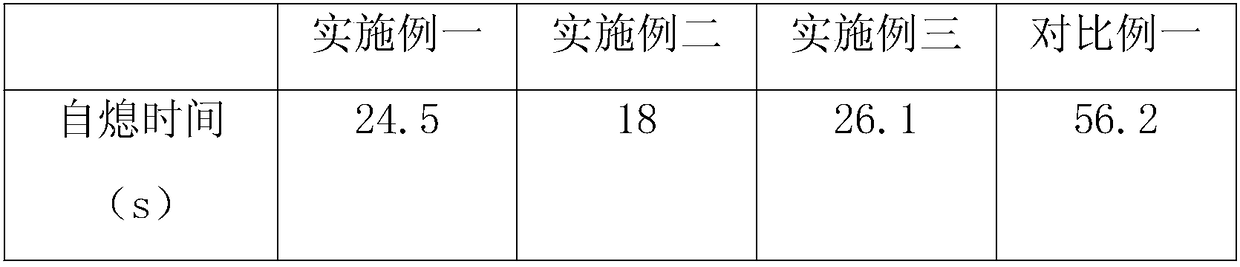

Examples

Embodiment 1

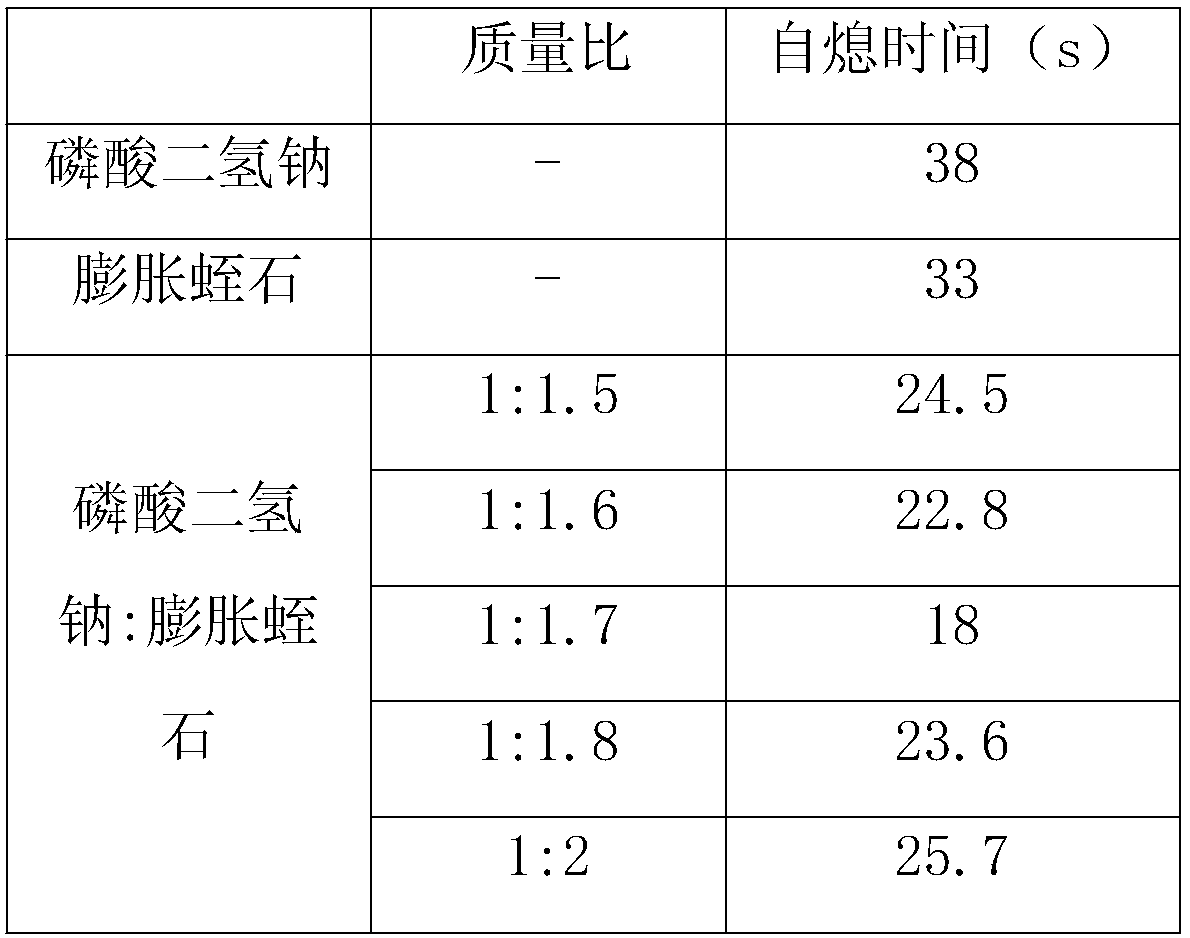

[0015] A thermoplastic elastomer halogen-free flame-retardant cable external material proposed by the present invention includes the following raw materials in parts by weight: 20 parts of thermoplastic polyurethane, 15 parts of polyethylene resin, 1 part of sodium dihydrogen phosphate, 1.5 parts of expanded vermiculite, palm 2 parts of ethyl acetate, 0.2 parts of anti-aging agent, and 0.2 parts of heat stabilizer.

[0016] Its preparation method comprises the following steps:

[0017] S1, adding the sodium dihydrogen phosphate and expanded vermiculite of the specific gravity into the grinder, and fully grind for 5 minutes to obtain the mixture A;

[0018] S2. Add the polyethylene resin with the specific gravity into the resin softening tank, heat at a high temperature of 160°C for 30 minutes, then raise the temperature to 200°C, add thermoplastic polyurethane, and mix and stir for 20 minutes to obtain a mixture B;

[0019] S3. Add the mixture A in step 1, the mixture B in st...

Embodiment 2

[0021] A thermoplastic elastomer halogen-free flame-retardant cable external-use material proposed by the present invention includes the following raw materials in parts by weight: 25 parts of thermoplastic polyurethane, 23 parts of polyethylene resin, 1.8 parts of sodium dihydrogen phosphate, 2.5 parts of expanded vermiculite, palm 2.6 parts of ethyl acetate, 0.27 parts of anti-aging agent, and 0.3 parts of heat stabilizer.

[0022] Its preparation method comprises the following steps:

[0023] S1, adding the sodium dihydrogen phosphate and expanded vermiculite of the specific gravity into a grinder, and fully grind for 10 minutes to obtain a mixture A;

[0024] S2. Add the polyethylene resin with the specific gravity into the resin softening tank, heat at a high temperature of 180°C for 45min, then raise the temperature to 230°C, add thermoplastic polyurethane, and mix and stir for 25min to obtain a mixture B;

[0025] S3. Add the mixture A in step 1, the mixture B in step ...

Embodiment 3

[0027] A thermoplastic elastomer halogen-free flame-retardant cable external material proposed by the present invention includes the following raw materials in parts by weight: 30 parts of thermoplastic polyurethane, 35 parts of polyethylene resin, 2.5 parts of sodium dihydrogen phosphate, 5 parts of expanded vermiculite, palm 3 parts of ethyl acetate, 0.3 parts of anti-aging agent, and 0.5 parts of heat stabilizer.

[0028] Its preparation method comprises the following steps:

[0029] S1, adding the sodium dihydrogen phosphate and expanded vermiculite of the specific gravity into the grinder, and fully grind for 15 minutes to obtain the mixture A;

[0030] S2. Add the polyethylene resin of the specific gravity into the resin softening tank, heat at a high temperature of 200°C for 60 minutes, then raise the temperature to 250°C, add thermoplastic polyurethane, and mix and stir for 30 minutes to obtain a mixture B;

[0031] S3. Add the mixture A in step 1, the mixture B in st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com