Low-molecular weight siliceous acrylic resin for photosensitive silver paste and preparation method thereof

A low-molecular-weight, silico-acrylic technology, used in optomechanical equipment, optics, photolithography on patterned surfaces, etc., and can solve problems such as line adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The photosensitive silver paste described in this embodiment is prepared by the following method with low molecular weight silicon-containing acrylic resin:

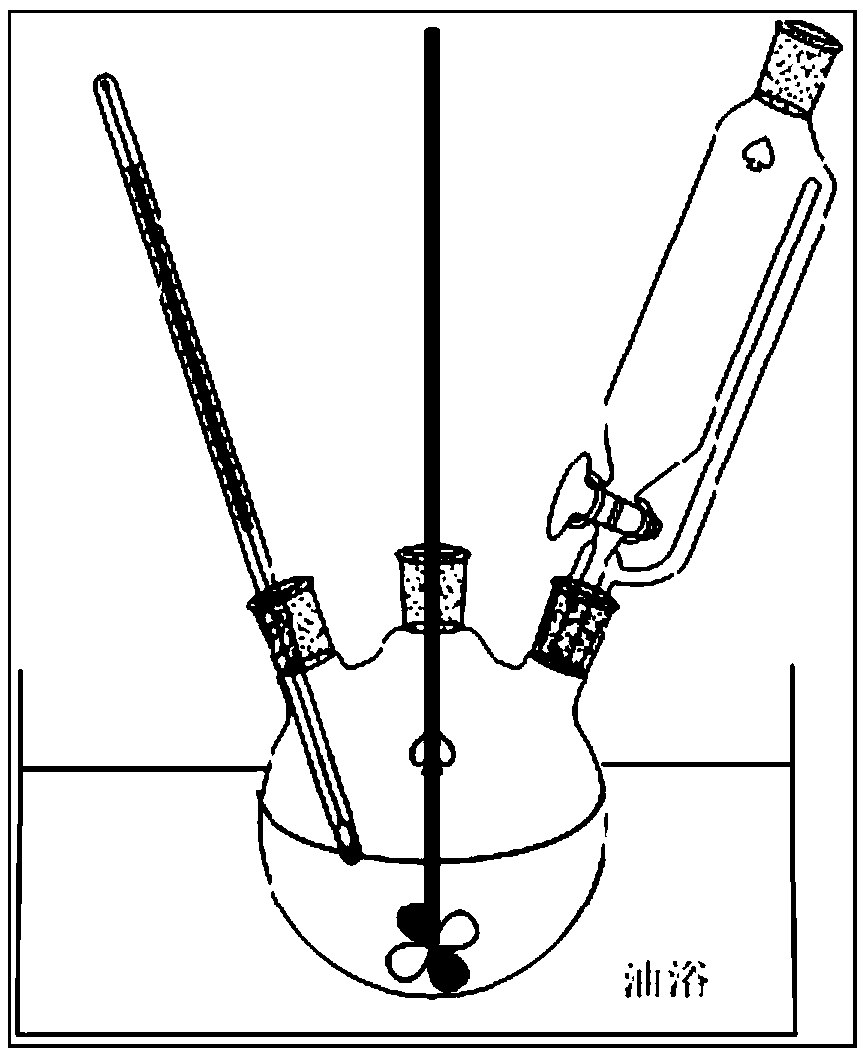

[0034] Under a nitrogen atmosphere, 100g of dipropylene glycol methyl ether and 0.005g of benzoyl peroxide were packed into a 500mL four-necked flask with mechanical stirring, a thermometer and a reflux condenser, and placed in an oil bath at 60°C (such as figure 1 shown). 99.9 g of methyl methacrylate, 0.1 g of methacrylic acid, 0.005 g of acryloxypropyltrimethoxysilane, 0.01 g of initiator and 0.01 g of chain transfer agent were mixed and transferred to a constant pressure dropping funnel. When the temperature in the reaction flask reached 60°C, the constant pressure dropping funnel was opened, and the mixture was added dropwise and reacted for 1 h. Raise the temperature to 70°C for 1 hour, cool to room temperature and store in a PP plastic bottle; the photosensitive silver paste obtained in this example has a ...

Embodiment 2

[0036] The photosensitive silver paste described in this embodiment is prepared by the following method with low molecular weight silicon-containing acrylic resin:

[0037] Under a nitrogen atmosphere, 100g of n-butanol and 0.05g of benzoyl peroxide were packed into a 500mL four-neck flask with mechanical stirring, a thermometer and a reflux condenser, and placed in an oil bath at 70°C (such as figure 1 shown). 80g of methyl methacrylate, 10g of acrylic acid, 10g of butyl acrylate, 0.05g of acryloxypropyltriethoxysilane, 0.05g of initiator and 0.05g of chain transfer agent were mixed and transferred to a constant pressure dropping funnel. When the temperature in the reaction flask reached 70°C, the constant pressure dropping funnel was opened, and the mixture was added dropwise and reacted for 2 hours. Raise the temperature to 80°C for 2 hours, cool to room temperature and transfer to PP plastic bottle for storage. The molecular weight of the low molecular weight silicon-con...

Embodiment 3

[0039] The photosensitive silver paste described in this embodiment is prepared by the following method with low molecular weight silicon-containing acrylic resin:

[0040] Under a nitrogen atmosphere, 233g terpineol and 0.1g benzoyl peroxide were packed into a 500mL four-necked flask with mechanical stirring, a thermometer and a reflux condenser, and placed in an oil bath at 80°C (such as figure 1 shown). 70g methyl methacrylate, 50g maleic anhydride, 30g isobutyl methacrylate, 10g hydroxyethyl methacrylate, 0.1g methacryloxypropylmethyldimethoxysilane, 0.1g initiator Agent and 0.1g chain transfer agent were mixed and transferred to a constant pressure dropping funnel. When the temperature in the reaction flask reached 80°C, the constant pressure dropping funnel was opened, and the mixture was added dropwise and reacted for 3 hours. Raise the temperature to 90°C for 3 hours, cool to room temperature and transfer to PP plastic bottle for storage. The molecular weight of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com