High-capacity potassium-oxygen battery

An oxygen battery, high-capacity technology, applied in the direction of fuel cell half-cells and primary battery-type half-cells, can solve the problems of limiting battery capacity and energy efficiency, limiting battery cycle life, and promoting electrolyte decomposition, etc., to achieve Inhibition of surface side reactions, good practical value, and small charge and discharge overpotential effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1. Assembly of potassium-oxygen battery

[0041]The positive electrode of the potassium-oxygen battery is carbon paper (Toray TGP-H-60), the negative electrode is metal potassium sheet, and the electrolyte is 1mol / L KPF 6 / Diethylene glycol dimethyl ether solution, the diaphragm is a glass fiber diaphragm (WhatmanGF / D), and a piece of nickel foam is added as a shrapnel to meet the needs of the battery thickness, and assembled into a CR2025 button battery with oxygen diffusion holes, which will be assembled The CR2025 button battery is charged and discharged in a test device with an oxygen pressure of 1atm.

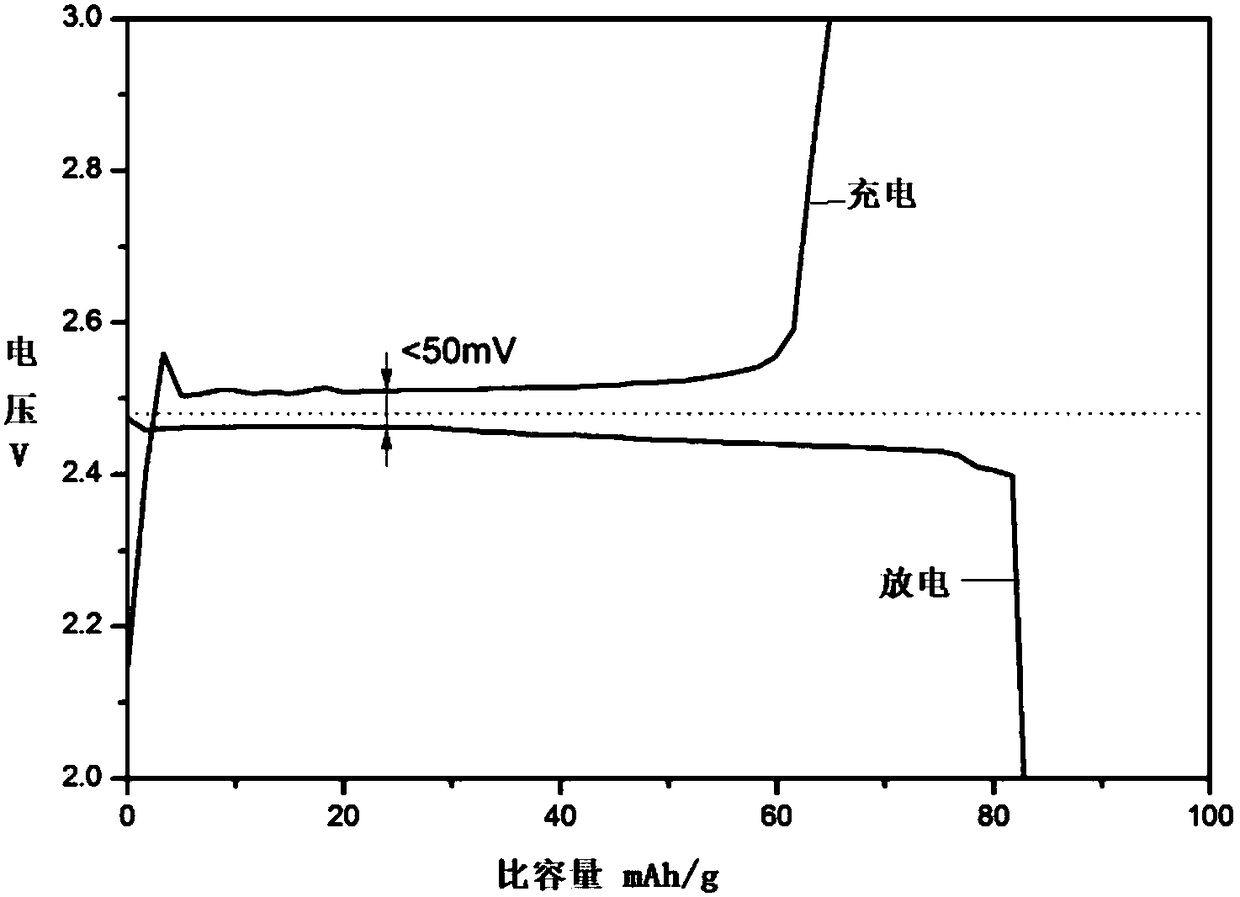

[0042] 2. Battery charge and discharge test

[0043] The charge and discharge cut-off voltage is 2V ~ 3V, and the charge and discharge current density is 0.1mA / m 2 , see the charging and discharging results figure 1 . Depend on figure 1 It can be seen from the first charge and discharge that when carbon paper is used as the electrode material, the overpotential...

Embodiment 2

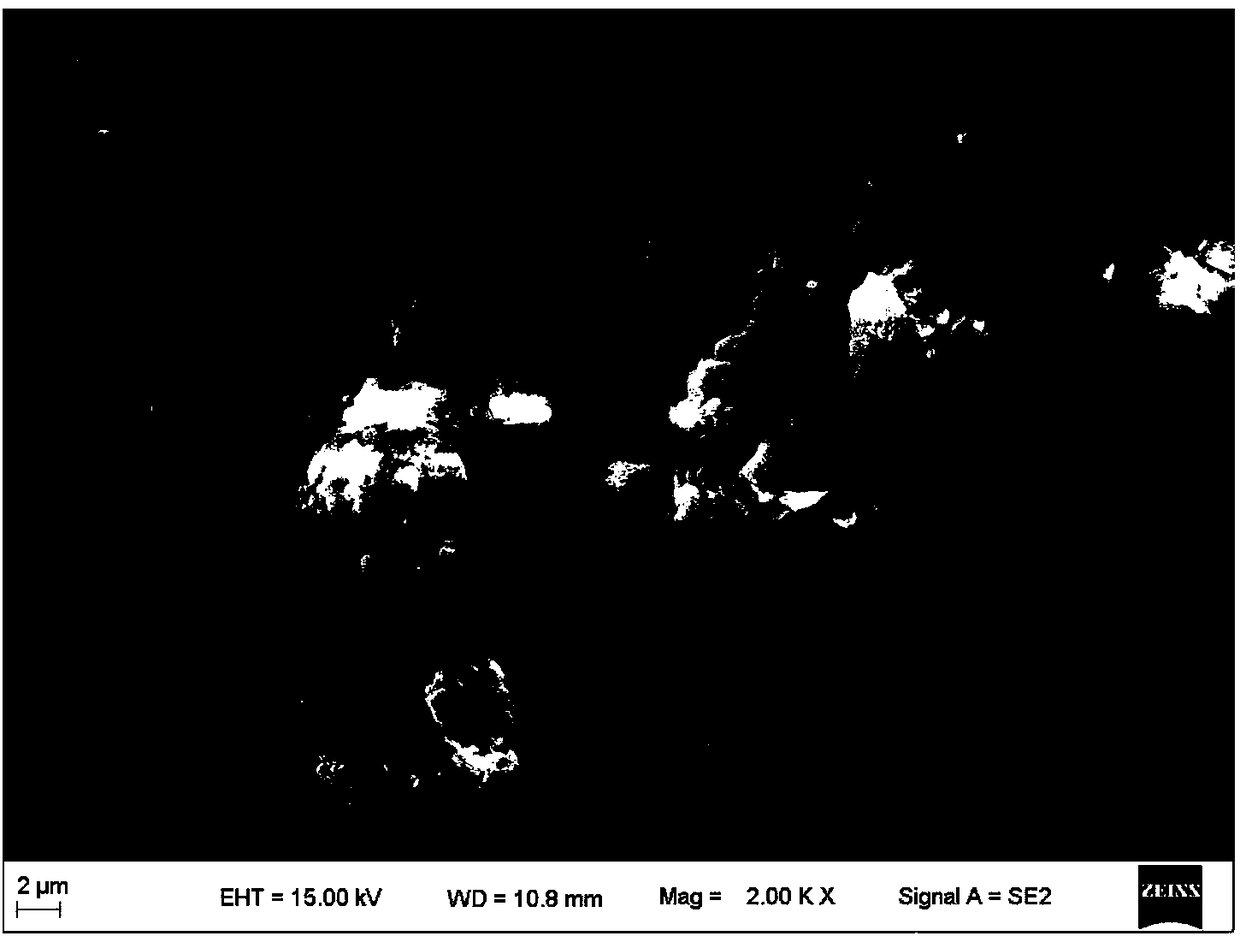

[0047] 1. Preparation of Oxygen Cathode

[0048] SuperP was vacuum baked at 120°C for 8 hours, PTFE with a concentration of 5% (the solvent was water), the ratio of SuperP and PTEF was 9:1, and an appropriate amount of ethanol was added to stir it into a viscous shape, and evenly coated on the carbon paper. After baking at 80°C for 8 hours, punch it into round pole pieces , vacuum-baked at 120° C. for 8 hours, and moved into a glove box for later use.

[0049] 2. Assembly of potassium-oxygen battery

[0050] The SuperP electrode prepared in the first part is the positive electrode of the potassium-oxygen battery, the metal potassium is the negative electrode, and the electrolyte is 1mol / L KPF 6 / Diethylene glycol dimethyl ether solution, the diaphragm is a glass fiber diaphragm (WhatmanGF / D), and a piece of nickel foam is added as a shrapnel, assembled into a CR2025 button battery with oxygen diffusion holes, and the CR2025 button battery is put into oxygen pressure Charge...

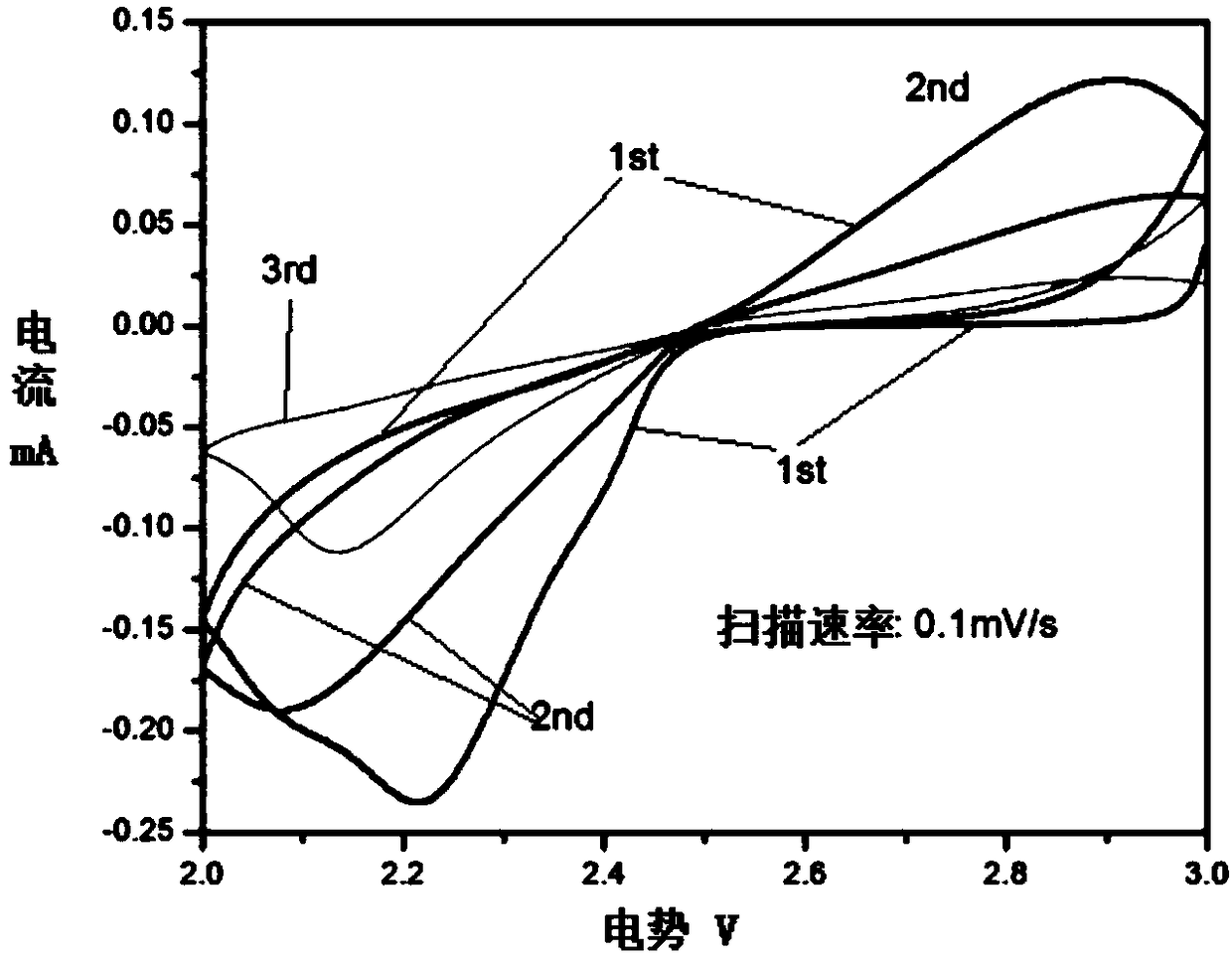

Embodiment 3

[0057] 1. Preparation of Oxygen Cathode

[0058] SuperP is vacuum baked at 120°C for 8 hours, and PTFE with a concentration of 5% (the solvent is water) is added. The ratio of SuperP and PTEF is 9:1. Add an appropriate amount of ethanol and stir it into a viscous shape, and evenly coat it on the nickel foam. After baking at 80°C for 8 hours, punch it into round pole pieces , vacuum-baked at 120° C. for 8 hours, and moved into a glove box for later use.

[0059] 2. Assembly of potassium-oxygen battery

[0060] The SuperP electrode prepared in the first part is the positive electrode of the potassium-oxygen battery, the metal potassium is the negative electrode, and the electrolyte is 1mol / L KPF 6 / diethylene glycol dimethyl ether solution, the diaphragm is a glass fiber diaphragm (WhatmanGF / D), and a piece of nickel foam is added as a shrapnel to assemble a CR2025 button battery with oxygen diffusion holes. Put the assembled CR2025 button battery with oxygen diffusion holes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com