Efficient circulation modification smelting method for RH furnace steel ladle top slag

A smelting method and upgrading technology, which is applied in the field of iron and steel metallurgy and steelmaking, can solve the problems of product composition stability and the influence of pass rate, the modifier cannot fully react with the slag surface, and the carbon at the end of the decarburization effect is too high, so as to avoid Secondary oxidation pollution, good kinetics and slag adsorption capacity, solve the effect of improving the inclusion removal function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

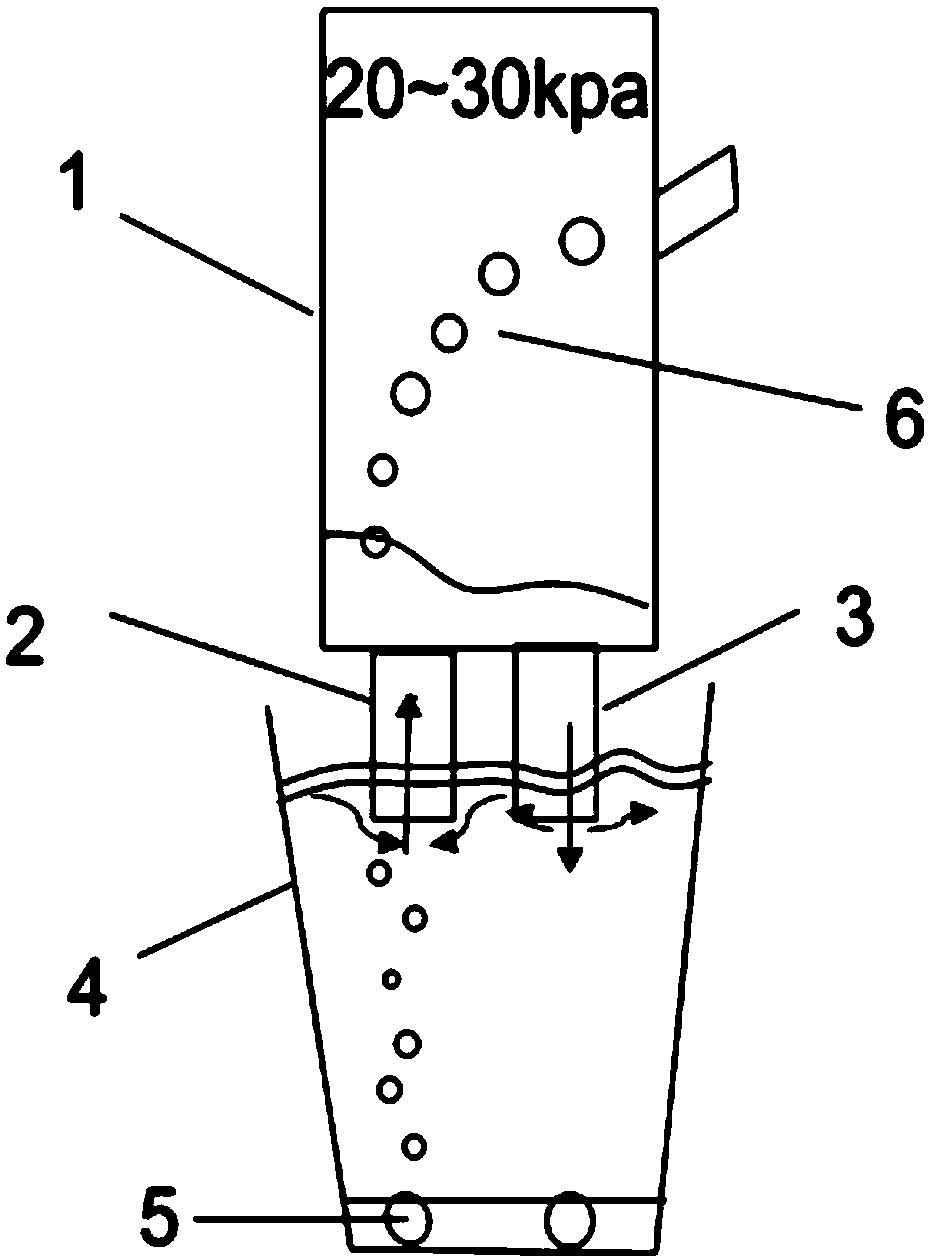

[0028] combine figure 1 As shown, a RH furnace ladle top slag efficient circulation upgrading smelting method. In the present invention, the slag is modified after deep decarburization and alloying in the RH furnace; the vacuum degree of the vacuum tank is controlled within 20-30 Pa; the depth of the dipping tube inserted into the molten steel is between 250-300 mm; The argon circulation gas rises into the vacuum tank 1, and the molten steel flows into the ladle 4 from the downcomer 3 after being degassed, and the molten steel forms a closed loop flow on the upper layer of the ladle 4; at the same time, the ladle bottom blowing 5 bottom blowing argon at the ladle ascending pipe position (the pressure is 0.2 ~0.4Mpa, the flow rate is 30~50NL / min); the amount of modifier 6 added in the vacuum tank 1 is 200~300kg, and the ladle slag is deoxidized and modified by using the rapid reaction of the steel slag interface.

[0029] An RH furnace ladle top slag efficient circulation upgr...

Embodiment 2

[0037]When smelting strip ultra-low carbon steel (grade: DCO4-S), the converter-RH furnace-CC process is adopted, and the RH furnace adopts the deep treatment smelting mode. Furnace number H183-1250, continuous casting machine section 175×1270mm, entry temperature 1601°C, oxygen 450ppm; oxygen blowing temperature rise 25°C; vacuum pump to full pump (level 5), vacuum degree controlled within 67pa, end point after natural decarburization of molten steel Carbon: 13ppm; add 140kg of aluminum particles + 110kg of high titanium for deoxidation and alloying; operate according to the steps of the invention, recompress and leave the station to sample and analyze the top slag of the ladle, the results are shown in Table 1:

[0038] Table 1 Sampling and analysis results of ladle top slag

[0039] TF

Embodiment 3

[0041] When smelting strip ultra-low carbon steel (grade: DCO4), the converter-RH furnace-CC process is adopted, and the RH furnace adopts the deep treatment smelting mode. Furnace number H181-1420, cross-section of continuous casting machine 175×1270mm; entry temperature 1611°C, oxygen 480ppm; oxygen blowing temperature rise 15°C; vacuum pump to full pump (level 5), vacuum degree controlled within 67pa, end point after natural decarburization of molten steel Carbon: 14ppm; add 150kg of aluminum particles + 110kg of high titanium for deoxidation and alloying; operate according to the steps of the invention, repress and leave the station to sample and analyze the top slag of the ladle, the results are shown in Table 2:

[0042] Table 2 Sampling and analysis results of ladle top slag

[0043] TF

SiO 2

CaO

MgO

Al 2 o 3

1.59

6.0

36.75

6.76

6.13

23.12

[0044] From the results of the invention examples, when s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com