Coproduction technology of titanium white, iron oxide red and polymerized chlorinated ferrous sulfate

A technology for chlorinating ferrous sulfate and ferrous sulfate solution, which is applied in the chemical industry, can solve the problems of high cost of by-product treatment, poor removal ability of non-ferrous impurities, small pollution, etc., to achieve diversified utilization and shorten production cycle , The effect of stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

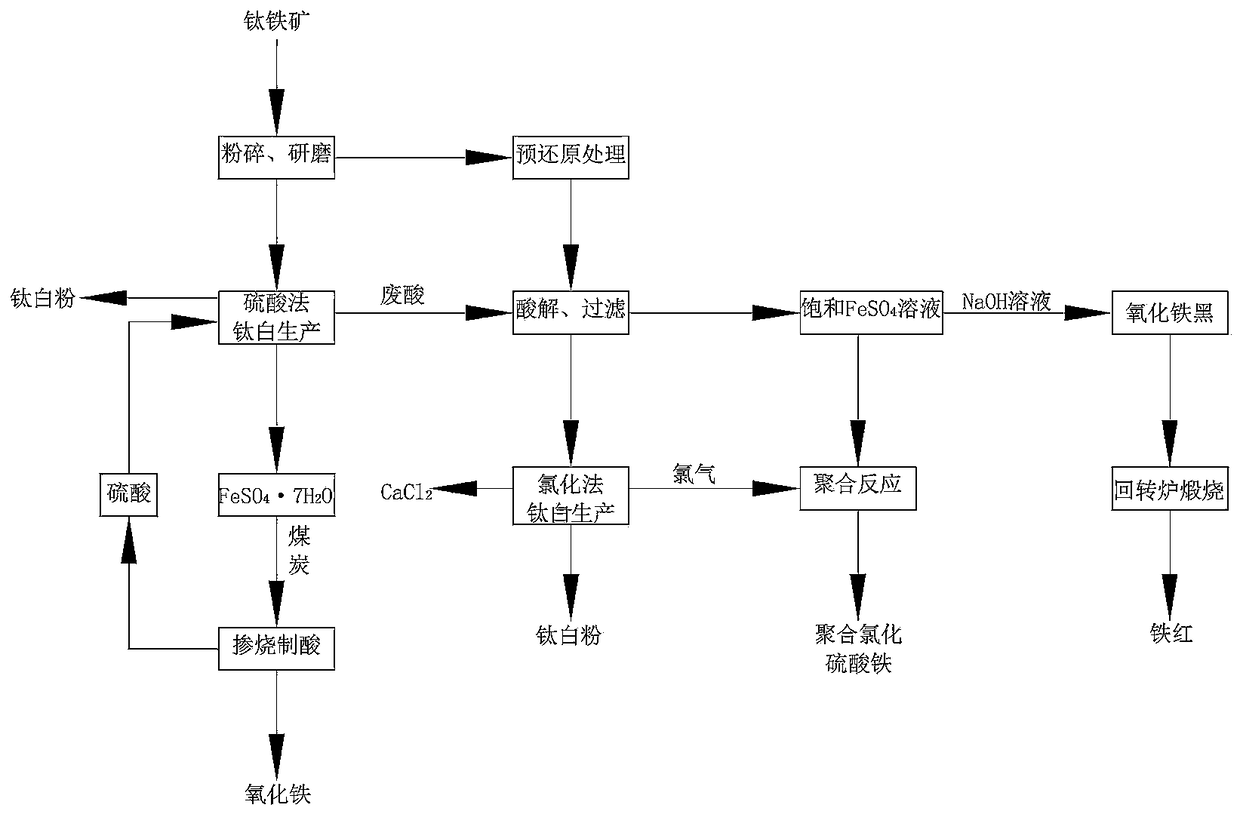

[0037] A kind of coproduction technique of titanium dioxide, iron red, polyferrous chloride chloride comprises the following steps:

[0038] Step1, pretreatment, pulverizing and grinding the ilmenite ore, part of it is used as raw material for sulfuric acid titanium dioxide production, and part of it is sent to ilmenite pre-reduction treatment;

[0039] Step2, sulfuric acid titanium dioxide production, the ilmenite ore after crushing and grinding in Step1 is carried out sulfuric acid titanium dioxide production, to obtain titanium dioxide, ferrous sulfate heptahydrate and waste acid;

[0040] Step3, acid hydrolysis, take the ilmenite that has been pre-reduced in Step1, add it to the waste acid produced in Step2 to mix and react, and perform solid-liquid separation after a period of reaction, wherein the solid phase is washed and dried The obtained synthetic rutile is used for the production of titanium dioxide by the chloride method, and the liquid phase is a saturated ferrous...

Embodiment 2

[0046] Under the conditions based on Example 1, the metallization rate of ilmenite after reduction was 85%, and the concentration of waste sulfuric acid used was 13%, and reacted for 0.5h at a certain ratio to obtain a synthetic rutile product of 86 grades;

[0047] Then add 20% sodium hydroxide solution to the saturated ferrous sulfate solution, control the pH value to 11, and react at 80°C for 3 hours to obtain a black iron oxide sample;

[0048] Further, using the above-mentioned iron black sample as raw material, calcining at 650°C for 1 hour to obtain an iron red sample;

[0049] Put the saturated ferrous sulfate solution in a closed reaction container, continue to circulate chlorine gas, the reaction temperature is 50°C, react for 12 hours, the pH value is reduced to 0.5, and the polymerized ferric sulfate chloride is obtained.

Embodiment 3

[0051] Under the conditions based on Example 1, the metallization rate of ilmenite after reduction is 90%, and the concentration of waste sulfuric acid used is 22%, and reacted for 1h at a certain ratio to obtain a synthetic rutile product of 91 grades;

[0052] Then add 20% sodium hydroxide solution to the saturated ferrous sulfate solution, control the pH value to 8, and react at 90°C for 4 hours to obtain a black iron oxide sample;

[0053] Further, using the above-mentioned iron black sample as raw material, calcining at 500°C for 3 hours to obtain an iron red sample;

[0054] Put the saturated ferrous sulfate solution in a closed reaction container, continue to circulate chlorine gas, the reaction temperature is 70°C, react for 6 hours, the pH value is reduced to 0.3, and the polymerized ferric sulfate chloride is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com